3PL vs 4PL: Differences in Supply Chain Management

Last updated on February 19, 2025

In this article

12 minutes

12 minutes

- Understanding Logistics Terminology

- Defining Third-Party Logistics (3PL): The Operational Experts

- Defining Fourth-Party Logistics (4PL): The Master Coordinators

- Advantages and Limitations of Each Model

- The Role of Technology in Shaping 3PL and 4PL Services

- Why Businesses Transition from 3PLs to 4PLs

- Industry-Specific Logistics Solutions

- Choosing the Right Logistics Model

- Frequently Asked Questions

As supply chain management has become more and more complex, ecommerce businesses have become more open to seeking external expertise from a logistics company to optimize their logistics workflows. Two primary business models have emerged to address these needs: third-party logistics (3PL) and fourth-party logistics (4PL). The pros and cons of each model make choosing between them a particularly personal decision, and the importance of that selection can have vastly different impacts on a company’s growth trajectory.

Understanding Logistics Terminology

Logistics terminology can be complex and overwhelming, especially for those new to the industry. Understanding the different types of logistics services and their definitions is crucial for making informed decisions about your supply chain. Here are some key terms to know:

- First-Party Logistics (1PL): This refers to a company that handles its own logistics operations. This includes everything from transportation to warehousing and inventory management. Essentially, the company is self-reliant and does not outsource any logistics activities.

- Second-Party Logistics (2PL): A 2PL is a company that provides transportation services but does not own or operate warehouses or inventory management systems. They are typically carriers or freight companies that move goods from one point to another.

- Third-Party Logistics (3PL): A 3PL provider offers a range of logistics services, including transportation, warehousing, and inventory management, on behalf of a client. They manage specific logistics functions, allowing businesses to focus on their core activities.

- Fourth-Party Logistics (4PL): A 4PL provider offers comprehensive supply chain management services. They oversee the entire supply chain, including freight forwarding and customs clearance for import/export, logistics, transportation, inventory management, and reverse logistics (ecommerce returns), often coordinating multiple 3PLs and other service providers.

- Lead Logistics Provider (LLP): Similar to a 4PL, an LLP provides comprehensive supply chain management services. They act as the single point of contact for all logistics activities, ensuring seamless coordination and integration across the supply chain.

Defining Third-Party Logistics (3PL): The Operational Experts

Third-party logistics providers are companies that specialize in executing specific logistics functions. Their primary role involves managing core operational tasks such as managing receiving and safe storage of inventory, and ecommerce order fulfillment when an order is received. By leveraging established infrastructure and expertise, 3PLs enable brands and retailers to focus on their core business while outsourcing the repetitive and tactical job.

3PLs typically own or lease their assets, including warehouse(s), storage racks and bins, software and hardware for managing operations, heavy equipment for moving large volumes of goods (e.g. forklifts), sometimes robots for picking and packing, sometimes a fleet of trucks for moving pallets of inventory, among other things. The idea is that online businesses can scale order volume up or down to follow peak seasons without the resource burden of building and maintaining their own internal logistics capabilities. The resulting relationship allows ecommerce companies to benefit from reliable and robust operational efficiency, (without the overhead of fixed assets, additional labor, and maintenance), while allowing them to retain strategic oversight of the supply chain.

Lastly, while 3PLs excel at managing the straightforward and individual parts of an arguably simple fulfillment workflow, they tend to lack the ability to optimize supply chains more holistically. It gets worse for brands and retailers that rely on multiple 3PLs which typically results in fragmented communication, reduced visibility, and increased regular maintenance of the inventory, technologies, and relationships, which disrupts the “seamless system” that is the point of outsourcing fulfillment operations in the first place.

Defining Fourth-Party Logistics (4PL): The Master Coordinators

Fourth-party logistics providers take a broader approach, positioning themselves as supply chain architects. Rather than performing logistics tasks directly, 4PLs orchestrate the relationships and efforts of multiple solution providers, including 3PLs, parcel and freight carriers, freight forwarders, etc., to streamline the entire supply chain network. Their role extends beyond logistics execution to include strategic consulting, risk management, and technology integration.

Operating as a single point of contact for all (or nearly all) logistics activities, 4PLs manage logistics on behalf of their clients, overseeing end-to-end supply chain operations, from booking ocean freight and customs clearance to shipment tracking and carrier claims for missed SLAs. Ecommerce businesses are still strategically aligned and may be responsible for much of the decision-making, (e.g. product sourcing, manufacturing relationships, procurement activities, and production schedules), but the consolidation of all the moving parts from factory to delivery, and even reverse logistics (e-commerce returns) into a single program governed by a single solution is what makes 4PLs special.

While 4PLs provide unmatched value for about the same money (or less), their services come with certain trade-offs. The most notable is a reduction in direct control over operational tasks, (same as with 3PLs), but in many cases, brands and retailers are using 4PLs to distribute inventory and take advantage of smart order routing to achieve the lowest final mile transportation costs possible. The participation of many staff across several locations often means even less control than with 3PLs (but with the cost advantages mentioned). Additionally, the initial costs associated with engaging a 4PL can be higher, but again, these are often offset by long-term efficiency gains. And the invention of new peer-to-peer 4PL business models has tapped into “excess capacity”, much as the gig economy has, to leverage even more competitive pricing.

In simpler terms:

- 3PL: Does the work

- 4PL: Manages the work done by others (including 3PLs)

Advantages and Limitations of Each Model

Both 3PLs and 4PLs offer distinct advantages tailored to specific business needs. For smaller organizations or those with straightforward logistics requirements, (e.g. don’t require aggressive delivery expectations such as the Amazon Seller Fulfilled Prime program), 3PLs provide cost-effective solutions and the ability to scale operations without significant capital investment (i.e. infrastructure, people, etc.). The 3PL model also allows businesses to retain more control while outsourcing mundane daily operational tasks.

However, the limitations of 3PLs become apparent as supply chains grow in complexity. Fragmented operations, reduced visibility, and communication challenges can hinder efficiency. In such cases, 4PLs tend to be a more suitable choice, offering a more comprehensive supply chain management solution by managing all supply chain activities, end-to-end optimization, and a consultative approach that includes insights that can help SMBs grow strategically. However, compared to smaller single-location 3PLs, (“mom and pop” operations), larger 3PLs that operate multiple locations can indeed offer more flexibility within their defined wheelhouse, including improved disaster recovery and the distributed inventory benefits already addressed.

The primary limitation of 4PLs is the reduced direct control over logistics operations. Again, still a limitation with outsourcing fulfillment to any provider, but more so with 4PLs because they manage more of the business’s requirements. Additionally, the initial investment required to engage a 4PL can be a barrier for smaller businesses (depending on the 4PL business model, as described previously). Nevertheless, the long-term benefits of improved efficiency and streamlined communication (what we call managed services) from the 4PL’s innovative supply chain solutions often outweigh these initial challenges.

In either model, Sellers are freed up to focus on product discovery, design, marketing, sales…growth. Which net-net, is a positive outcome.

The Role of Technology in Shaping 3PL and 4PL Services

Both 3PL and 4PL providers are leveraging tools such as artificial intelligence, real-time visibility, and predictive analytics to enhance their service offerings. While 3PLs use technology to optimize specific logistics functions, 4PLs integrate these tools across the entire network of vendors, consolidating visibility and operations into a single platform for unified decision-making and performance monitoring.

Some are already working on using agentic artificial intelligence for even more accurate demand forecasting and order and inventory management solutions including humanless procurement and intelligent inventory placement.

Benefits of Outsourcing Logistics Services

Outsourcing logistics services can bring numerous benefits to a company, enhancing efficiency and allowing businesses to focus on their core competencies. Here are some key advantages:

- Increased Efficiency: Logistics providers have the expertise and resources to optimize supply chain operations, reducing costs and improving delivery times. Their specialized knowledge ensures that logistics processes are streamlined and effective.

- Improved Customer Service: By providing real-time tracking and updates, logistics providers enhance customer satisfaction and loyalty. Customers appreciate the transparency and reliability that professional logistics services offer.

- Reduced Costs: Logistics providers can negotiate better rates with carriers and suppliers, leading to significant savings in transportation and inventory costs. Their established relationships and bulk purchasing power often result in lower expenses.

- Increased Flexibility: Logistics providers can quickly adapt to changing market demands and supply chain disruptions. This flexibility allows companies to respond effectively to unforeseen circumstances and maintain smooth operations.

- Access to Advanced Technology: Many logistics providers utilize advanced technology, such as transportation management systems, warehouse management systems, and inventory management systems. These tools provide valuable insights and improve overall supply chain performance.

Why Businesses Transition from 3PLs to 4PLs

The shift from 3PL to 4PL partnerships often follows the growth of a merchant’s business. As companies expand (or scale), their supply chains become more complex, more intricate, with requirements spanning more and more geographies, more vendors, and more sales channels. This complexity necessitates a move beyond the transactional focus of 3PLs toward the strategic value provided by 4PLs.

Several factors drive this migration:

- Increasing Complexity: Managing multiple 3PL relationships can result in fragmented operations and a lack of centralized oversight.

- Global Expansion: Businesses operating in international markets require sophisticated coordination to navigate cross-border logistics and compliance requirements.

- End-to-End Visibility: The need for real-time tracking and seamless integration across supply chain functions becomes paramount as more capital is tied up in more inventory in more places.

- Strategic Initiatives: Organizations pursuing innovative supply chain strategies benefit from the specialized expertise of 4PLs.

- Technology Support: The ability to consolidate all the disparate cogs of the wheel into a single platform with single points of contact is often one of the most deciding factors in the transition to 4PL services.

Industry-Specific Logistics Solutions

Different industries have unique logistics requirements, and logistics providers must be able to adapt to these needs. Here are some examples of industry-specific logistics solutions:

- Ecommerce Logistics: Ecommerce companies require fast and flexible logistics solutions to meet the demands of online shoppers. Logistics providers must offer real-time tracking, same-day shipping, and flexible return processes to ensure customer satisfaction.

- Pharmaceutical Logistics: Pharmaceutical companies need specialized logistics solutions to ensure the safe and secure transportation of temperature-sensitive products. Logistics providers must provide temperature-controlled transportation, secure storage, and comprehensive tracking and monitoring; also often requiring serialization and/or lot-tracking capabilities.

- Automotive Logistics: Automotive companies require logistics solutions that can handle the transportation of large and heavy parts, as well as the management of complex multinational supply chains. Logistics providers must offer specialized transportation services, including heavy haul and oversized loads that introduce diseconomies of scale.

- Food and Beverage Logistics: Food and beverage companies need logistics solutions that can handle the transportation of perishable products and management of complex supply chains. Logistics providers must provide temperature-controlled transportation, secure storage, and detailed tracking and monitoring to ensure product quality and safety. Often, they require registration with the Food and Drug Administration (FDA) to be able to track infectious diseases back to the source, or food-grade certification for the safe preparation, handling, and distribution of consumable food products.

By understanding and addressing the specific needs of different industries, logistics providers can offer tailored solutions that enhance supply chain efficiency and effectiveness.

Choosing the Right Logistics Model

The decision to outsource fulfillment operations to 3PL or 4PL services largely depends on a company’s size, internal operational capability, requirement for control (e.g. specialized products), and strategic priorities. Startups and smaller businesses may find the simpler nature of 3PLs sufficient to meet their logistics needs, often opting for a local business in or near their home community. Conversely, larger organizations with intricate supply chains and global reach more often require more comprehensive management provided by 4PLs. The shift signals a move from tactical to strategic supply chain management, enabling businesses to leverage expanded vendor involvement so they can concentrate on their core competencies.

As global markets evolve and supply chains become increasingly dynamic, the distinction between 3PLs and 4PLs will likely continue to shift. Businesses must carefully evaluate their current logistics needs while considering both current requirements and future growth objectives.

Frequently Asked Questions

What is an example of 4PL?

Amazon: As one of the world’s largest e-commerce platforms, it is one of the most well-known examples of 4PL. Amazon offers a comprehensive 4PL solution, including warehousing, transportation, and inventory management, all under one “roof”.

What is 3PL vs 4PL vs 5PL?

When looking for a logistics provider, there’s a good chance you’ll come across the terms 3PL, 4PL, and 5PL (and sometimes 6PL, 7PL, and 8PL). Short for third-party logistics, fourth-party logistics, and fifth-party logistics, respectively, they are essentially used to describe the breadth of services offered by an external logistics provider.

When would you use a 4PL instead of a 3PL?

Scalability: If your business anticipates significant growth in the future, partnering with a 3PL may provide more flexibility to adapt to changes. 4PLs may offer better solutions for businesses that need comprehensive management and coordination across multiple solution providers.

Why choose 4PL?

The 4PL acts as a strategic orchestrator, managing the entire supply chain and coordinating the logistics functions performed by 3PLs. This cooperation allows the 4PL to optimize supply chain operations for maximum efficiency and cost-effectiveness.

Why would a company choose to use a 4PL?

If you’re looking for a single point of control over your entire supply chain, a 4PL can provide this by managing all aspects of logistics from suppliers to end customers and then back again (reverse logistics). With extensive and rich partner networks, 4PLs can often achieve economies of scale that 3PLs cannot.

Is Walmart a 3PL?

Order fulfillment at Walmart is a service provided by Walmart Fulfillment Services (WFS) for ecommerce Sellers on the Walmart Marketplace platform. WFS works like many other third-party logistics services (3PL), where Walmart’s team takes charge of your inventory management and order fulfillment operations.

What is 4PL in simple words?

Fourth-party logistics, also known as 4PL, is an operational model in which a business outsources its entire supply chain management and logistics to one external service provider.

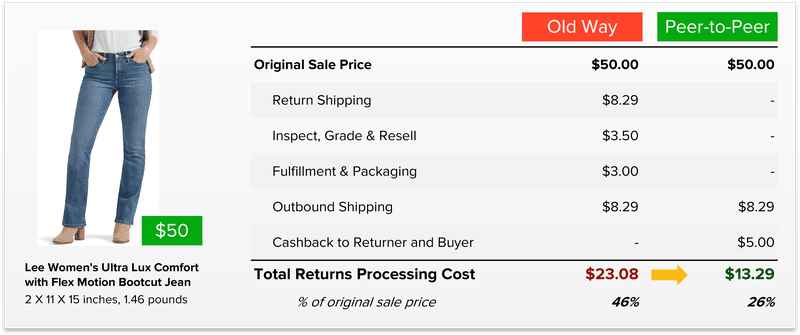

Up to 64% Lower Returns Processing Cost