Understanding the Relationship of 3PLs and Dropship Services

Last updated on February 28, 2025

In this article

17 minutes

17 minutes

- Understanding 3PL (Third-Party Logistics)

- Advantages of 3PLs

- Disadvantages of 3PLs

- Understanding Dropshipping

- Advantages of Dropshipping

- Disadvantages of Dropshipping

- Key Differences Between 3PL and Dropshipping

- How Dropshipping and 3PLs Interact

- Full Service Automation Integrations (Dynamic Fulfillment)

- Challenges of Managing Inventory in Dropshipping

- Future Outlook

- Conclusion

- Frequently Asked Questions

In today’s rapidly evolving ecommerce landscape, entrepreneurs are constantly seeking efficient ways to manage inventory, fulfill orders, and scale their businesses. Two popular models that frequently intersect are third-party logistics (3PL) and dropshipping. While these terms are sometimes used interchangeably, they represent distinct approaches to supply chain management, each with unique advantages and considerations.

Understanding 3PL (Third-Party Logistics)

What is 3PL?

A third-party logistics provider (3PL) is a company that offers outsourced logistics services, including fulfillment services, handling various aspects of the supply chain on behalf of another business. 3PL providers essentially function as extensions of a business’s operations, taking over the physical aspects of inventory management and order fulfillment while the business focuses on product development, marketing, and customer relationships.

How 3PLs Work

The typical 3PL relationship begins when a business sends its inventory to the 3PL’s warehouse facilities. The 3PL then:

- Receives and catalogs inventory

- Stores products in organized warehouse spaces

- Integrates with the business’s ecommerce platform

- Processes incoming orders automatically

- Picks, packs, and ships orders to end customers

- Provides tracking information and delivery updates

- Handles returns and exchanges as needed, ensuring efficient order fulfillment throughout the entire process

Advantages of 3PLs

Using a 3PL provider can bring numerous benefits to a business, including:

- Expertise and Infrastructure: 3PLs offer specialized logistics knowledge and advanced infrastructure (warehouse systems, equipment) that would be costly for businesses to develop independently.

- Scalability: Businesses can rapidly scale operations during peak periods (handling 5-10x normal volume) without investing in additional resources, and avoid excess capacity costs during slower periods.

- Focus on Core Competencies: By outsourcing logistics, businesses can redirect energy toward strategic activities like product innovation, marketing, and customer relationships.

- Geographic Expansion: 3PLs with networks of fulfillment centers enable businesses to reduce shipping times and costs, offer competitive delivery options, and expand internationally with minimal risk.

- Cost Efficiency: 3PLs negotiate lower shipping rates (25-50% less), convert fixed costs to variable expenses, and can reduce total fulfillment costs by 15-30% compared to in-house operations.

Disadvantages of 3PLs

3PL providers also have disadvantages:

- Loss of Control: Businesses surrender direct oversight of fulfillment operations, creating accountability challenges when problems arise and limiting ability to make real-time adjustments.

- Setup Costs and Minimums: Initial onboarding fees ($500-$5,000) and monthly minimums ($500-$2,000) create financial barriers, especially for startups or businesses with fewer than 100-200 monthly orders.

- Integration Challenges: Connecting ecommerce platforms with 3PL systems can be technically complex, requiring substantial development work and ongoing maintenance.

- Reduced Branding Opportunities: Standard 3PL procedures prioritize efficiency over customization, limiting opportunities for distinctive packaging and unboxing experiences.

- Additional Fees: Ancillary charges for long-term storage, special handling, returns processing, and other services can increase fulfillment costs by 20-40% above base rates.

Understanding Dropshipping

What is Dropshipping?

Dropshipping is a retail fulfillment model where online stores don’t keep products in stock. Instead, when a customer places an order, the store purchases the item from a third party (usually a manufacturer or wholesaler) who ships the product directly to the customer. The seller never handles the product physically but acts as a middleman between supplier and customer. Dropshipping fulfillment services play a crucial role in this model by partnering with third-party logistics providers (3PLs) to manage order fulfillment, scale operations, and enhance customer experience.

How Dropshipping Works

- A customer places an order on the seller’s ecommerce store

- The seller automatically or manually forwards the order details to the supplier

- The supplier processes the order, packages the product, and ships it directly to the customer

- The seller keeps the margin between their retail price and the supplier’s wholesale price

Advantages of Dropshipping

Low Startup Costs

Dropshipping fundamentally transforms the economics of launching an ecommerce business by virtually eliminating upfront inventory investment. Traditional retail models typically require $10,000-$100,000+ in initial inventory purchases before selling a single product, creating significant financial barriers to entry. With dropshipping, entrepreneurs can establish fully operational online stores with investments as low as $100-$500, primarily covering website hosting, ecommerce platform subscriptions, and basic marketing expenses.

Reduced Overhead

The operational simplicity of dropshipping eliminates numerous fixed costs that typically burden traditional ecommerce businesses. Without physical inventory, entrepreneurs avoid warehouse leases ($2,000-$10,000+ monthly depending on location and size), utilities, insurance, security systems, and maintenance expenses. The absence of inventory handling eliminates the need for forklifts, shelving systems, packaging stations, and other warehouse equipment—investments that typically cost $25,000-$100,000 for even modest operations.

Perhaps most significantly, dropshipping businesses avoid the substantial personnel costs associated with traditional fulfillment: no warehouse managers ($50,000-$80,000 annually), pickers and packers ($15-$20/hour), receiving staff, or inventory control specialists.

Location Independence

Dropshipping liberates entrepreneurs from geographic constraints. Since the business operates entirely through digital interfaces; ecommerce platforms, supplier portals, marketing tools, and communication systems, owners can manage operations from anywhere with reliable internet connectivity.

This location independence enables diverse business scenarios impossible in traditional retail: digital nomads running seven-figure stores while traveling continuously, entrepreneurs accessing global markets from rural areas with limited local opportunities, expatriates building businesses serving their home countries while living abroad, or parents operating substantial enterprises around family responsibilities from home offices.

Wide Product Selection

Dropshipping fundamentally transforms inventory economics, enabling businesses to offer expansive product catalogs that would be financially impossible under traditional inventory models. While conventional retailers might stock 500-2,000 SKUs based on capital constraints and warehouse space, dropshipping stores routinely offer 10,000+ products without incremental investment or operational complexity.

This catalog flexibility creates multiple strategic advantages: the ability to function as comprehensive category destinations rather than specialized boutiques, opportunities to capture long-tail search traffic across thousands of specific product queries, and the capacity to rapidly adapt to emerging trends without inventory liquidation concerns. The breadth of selection enables sophisticated merchandising strategies like “good-better-best” pricing tiers, complementary product ecosystems, and comprehensive solution selling across related categories.

Easy to Test Products

The ability to rapidly test new products with minimal financial risk represents one of dropshipping’s most powerful strategic advantages, enabling an iterative, data-driven approach to product selection impossible in traditional retail.

With conventional inventory models, adding a new product typically requires committing to minimum order quantities (often 100+ units), investing $500-$5,000 before knowing if the item will resonate with customers.

Dropshipping transforms this equation—entrepreneurs can add dozens or hundreds of products to their stores in days, investing only the time required for product research and listing creation.

Disadvantages of Dropshipping

Lower Profit Margins

While traditional retailers typically achieve 50-80% gross margins through direct manufacturer relationships and volume purchasing, dropshipping businesses generally operate with 15-30% margins due to working through intermediaries who capture significant value in the supply chain.

This margin pressure intensifies in highly visible product categories where price competition is transparent and fierce. The competitive landscape exacerbates these challenges—the low barriers to entry create saturated markets where numerous sellers offer identical products, frequently triggering price wars that further erode margins.

Expensive Shipping

Unlike traditional ecommerce where orders are fulfilled from a single warehouse, dropshipping frequently involves multiple suppliers shipping independently to the same customer. When customers purchase multiple products in a single order that source from different suppliers, they receive multiple shipments — a three-item order from three suppliers typically generates shipping charges 200-300% higher than consolidated fulfillment, substantially eroding profitability or forcing difficult decisions about shipping subsidies.

Inventory Issues

The absence of direct inventory control creates persistent operational vulnerabilities for dropshipping businesses, particularly regarding stock availability and accuracy. Unlike traditional retail where inventory is physically on-hand and continuously monitored, dropshippers rely entirely on supplier inventory systems that vary dramatically in sophistication and reliability. Inventory data typically refreshes only periodically (every few hours or daily), creating windows where items showing as available may actually be depleted.

This inventory opacity produces the dropshipping model’s most dreaded scenario: processing customer orders for products that prove to be unavailable, necessitating cancellations, backorders, or substitutions that damage customer trust and generate negative reviews.

Quality Control Challenges

The inability to physically inspect products before they reach customers creates fundamental quality assurance challenges unique to the dropshipping model. Traditional retailers implement multiple quality checkpoints; receiving inspections, periodic inventory audits, and final verification during picking, to ensure customers receive merchandise matching expected specifications and in good condition.

Dropshippers, however, rely entirely on suppliers’ quality processes, effectively outsourcing this critical aspect of customer experience with limited oversight capability. This quality control gap manifests in several problematic scenarios: products arriving with manufacturing defects that would have been caught in standard inspections, packaging damage during extended storage at supplier facilities, outdated or previous-generation products shipped without notification, and incorrect items due to supplier picking errors.

Supplier Dependency

The extreme reliance on suppliers as operational partners rather than merely product sources creates unique vulnerability for dropshipping businesses compared to inventory-based models. Traditional retailers maintain buffer inventory that insulates them from temporary supplier disruptions and provides negotiating leverage. Dropshippers, however, connect customer expectations directly to supplier performance without intermediary control points, creating existential dependency.

This dependency manifests across multiple business dimensions: any supplier fulfillment delay instantly becomes the dropshipper’s customer service problem, supplier stock maintenance directly determines product availability, supplier shipping methods define delivery timeframes, and supplier packaging represents the customer’s unboxing experience.

The relationship asymmetry often creates challenging power dynamics—suppliers typically prioritize their direct B2C operations and large wholesale accounts over dropshipping partners, creating service disparities during capacity constraints.

Key Differences Between 3PL and Dropshipping

Dropshipping: No Inventory Costs

The financial model of dropshipping centers on eliminating upfront inventory investment, creating a distinctive cash flow profile and cost structure. This capital efficiency extends throughout the business lifecycle, as product catalog expansions require no additional investment beyond digital assets and marketing. The tradeoff for this capital efficiency comes in unit economics—dropshipped products typically cost 30-50% more than equivalent items purchased in wholesale quantities, significantly compressing gross margins.

The 3PL fulfillment model creates a hybrid cost structure combining significant upfront inventory investment with professional fulfillment economics. Businesses must first purchase inventory at wholesale; this inventory ownership creates working capital requirements, carrying costs, and obsolescence risks absent in dropshipping, but enables wholesale pricing typically 30-50% lower than dropshipping sources.

3PLs allow Order Fulfillment Customization

Unlike inventory models where businesses control each fulfillment step, dropshippers must accept suppliers’ existing quality standards, packaging approaches, and shipping methods with minimal customization opportunity.

The 3PL fulfillment model creates a structured framework where businesses maintain significant control over critical customer experience elements while outsourcing operational execution.

3PL relationships operate as directed partnerships where the business establishes specifications, standards, and protocols executed by the 3PL. Businesses specify packaging materials, inserts, and presentation elements the 3PL implements.

Scalability

The dropshipping model offers unparalleled product catalog scalability while introducing distinctive operational scaling challenges as order volume increases. The model’s most significant scaling advantage lies in inventory breadth; businesses can expand from dozens to thousands of products without additional capital investment or operational complexity.

The 3PL model creates a structured framework for predictable operational scaling while requiring proportional capital investment to support growth.

Professional 3PLs maintain excess capacity designed to accommodate client growth and seasonal fluctuations, with sophisticated warehouse management systems, staffing models, and physical infrastructure capable of handling 5-10x volume increases during peak periods.

How Dropshipping and 3PLs Interact

3PL Warehouse for Dropshipping (Hybrid Inventory Model)

This hybrid approach balances owned inventory with dropshipped products to optimize both customer experience and business operations. Implementation typically begins with inventory segmentation analysis, where businesses analyze sales data to identify the top 20% of products that generate 80% of revenue (following the Pareto principle). Companies then employ demand forecasting techniques, using historical data and seasonality trends to predict which products should be stocked versus dropshipped. To manage this dual approach effectively, businesses implement specialized inventory management software such as Skubana, Linnworks, or InventorySource that can track both owned and dropshipped inventory in a unified dashboard. Many also set up automatic reordering systems, establishing par levels for 3PL-stored items with automatic purchase orders triggered when inventory reaches predetermined threshold levels.

The benefits of this hybrid model are substantial and multifaceted. Reduced stockouts ensure core products are always available for immediate shipment, while better cash flow management keeps capital tied up only in proven sellers. Customer satisfaction improves with faster delivery for the most common purchases. The approach also provides excellent risk mitigation, as new product lines can be tested via dropshipping before committing to inventory purchase. Seasonal flexibility allows businesses to expand offerings during peak seasons without warehouse expansion.

As a real-world example, a home goods retailer might stock their bestselling bedding collections with a 3PL while dropshipping decorative accessories, seasonal items, and furniture. This strategy allows them to ship core products quickly while offering an extensive catalog without the associated inventory costs.

Shipping 3PL for Dropshipping (2-Step Dropshipping)

This model creates a buffer between suppliers and customers, addressing many traditional dropshipping challenges. The process flow begins when a customer places an order on the merchant’s website. The order is then sent to the dropship supplier, who ships products to the merchant’s 3PL facility rather than directly to the customer. The 3PL receives, processes, repackages, and ships to the end customer, creating a more controlled fulfillment experience.

The infrastructure requirements for this approach include cross-docking facilities with dedicated areas within the 3PL warehouse for quickly processing incoming dropship orders. Quality control protocols establish standardized inspection procedures for all incoming dropshipped products. Custom packaging materials such as branded boxes, inserts, and marketing materials are stored at the 3PL. An order management system provides the software backbone that can track items from multiple suppliers through the consolidation process.

Additional advantages of this model include quality assurance, offering the opportunity to inspect products before they reach customers. Value-added services become possible, including personalization, gift wrapping, or custom inserts. Returns management is centralized, with potential for restocking suitable items. Shipping carrier optimization allows 3PLs to choose the most cost-effective shipping method for each package. Multi-channel fulfillment enables orders from various sales channels to be consolidated and fulfilled consistently.

Cost considerations should not be overlooked, as this approach typically incurs higher operational costs than direct dropshipping. These include an additional shipping leg from supplier to 3PL, 3PL handling and processing fees, potential storage fees for items awaiting consolidation, and often minimum monthly order volume requirements to be cost-effective.

Full Service Automation Integrations (Dynamic Fulfillment)

This sophisticated approach creates a unified ecosystem where fulfillment decisions are automated and optimized. Technical components include API-based integrations providing direct connections between ecommerce platforms, supplier networks, 3PL systems, and shipping carriers. Decision logic engines contain algorithms that determine the optimal fulfillment path based on multiple variables. Real-time inventory visibility offers live inventory feeds from both owned warehouse stock and dropship supplier availability. Shipping time calculators estimate delivery dates based on fulfillment method, carrier options, and destination. Middleware solutions such as Convictional, Fabric, or ChannelApe facilitate communication between disparate systems.

The advanced capabilities of this approach are significant. Split order fulfillment automatically divides orders for optimal processing, with some items coming from 3PL and others dropshipped. Geographic routing sends orders to the fulfillment option closest to the end customer. Margin-based routing chooses fulfillment methods that preserve profitability on each order. Dynamic supplier selection automatically chooses between multiple dropship suppliers based on availability, price, and performance. Predictive stocking uses AI to identify which dropshipped items should be converted to stocked inventory.

Challenges and considerations for this model include system complexity, which requires a sophisticated technology stack and often custom development work. Integration maintenance demands ongoing technical resources to maintain connections as platforms evolve. Exception handling processes must be established for managing orders when automated decisions encounter problems. Data synchronization ensures consistent information across all platforms in near real-time. Training requirements mean staff need understanding of complex systems and troubleshooting capabilities.

The implementation timeline typically requires 6-12 months for full deployment. Many businesses implement in phases, starting with core integrations and gradually expanding functionality. Extensive testing is necessary before full deployment to ensure all systems work seamlessly together and can handle various edge cases and exceptions.

Challenges of Managing Inventory in Dropshipping

Inventory management is a critical component of any dropshipping business, directly impacting customer satisfaction and profitability. However, managing inventory in a dropshipping model presents unique challenges. Unlike traditional retail, where businesses hold their own stock, dropshipping relies on third-party suppliers to maintain inventory levels.

- Stockouts: Running out of stock can lead to lost sales and disappointed customers. Without direct control over inventory, dropshipping businesses must rely on suppliers to keep stock levels updated, which can be unpredictable.

- Inventory Tracking: Keeping track of inventory levels across multiple suppliers can be complex. Accurate inventory tracking is essential to avoid stockouts and overstocking, but it can be challenging without the right systems in place.

- Supplier Management: Managing relationships with multiple suppliers can be difficult, especially when dealing with different lead times, shipping costs, and quality standards. Effective supplier management is crucial to ensure a reliable supply chain.

By outsourcing inventory management to a 3PL provider, dropshipping businesses can overcome these challenges. A 3PL provider can handle tasks such as inventory tracking, supplier management, and order fulfillment, ensuring that products are delivered to customers quickly and efficiently. This not only improves customer satisfaction but also enhances the overall efficiency and profitability of the dropshipping business.

Future Outlook

The next few years will likely see the emergence of hyperlocal fulfillment networks revolutionizing delivery expectations. These ultra-fast delivery systems will operate at the neighborhood level through micro-fulfillment centers, bringing products even closer to consumers and enabling delivery windows measured in hours rather than days.

Sustainability-driven distribution is rapidly transitioning from a marketing advantage to a competitive necessity. As consumers increasingly factor environmental impact into purchasing decisions, carbon-neutral fulfillment options will become standard offerings.

Automated decision optimization represents another major shift, with AI systems increasingly handling complex fulfillment decisions without human intervention. These sophisticated systems will analyze thousands of variables simultaneously—including inventory positions, carrier capacity, weather patterns, and customer preferences—to make optimal routing and fulfillment decisions in milliseconds.

The shopping experience itself will transform through AR/VR enhanced customer experiences, allowing virtual product interaction before purchase decisions. These technologies will bridge the gap between online convenience and in-store tactile experiences, reducing return rates by setting accurate expectations and increasing conversion rates by building purchase confidence.

These evolving models represent the cutting edge of ecommerce operations, blending the flexibility of dropshipping with the control and reliability of 3PL fulfillment to create resilient, scalable businesses that can compete effectively in today’s demanding market.

Conclusion

Both 3PL and dropshipping offer valuable approaches to ecommerce fulfillment, each with distinct advantages and challenges. While dropshipping provides a low-risk entry point for new entrepreneurs, 3PL services offer more control and potentially better economics at scale. Increasingly, successful ecommerce businesses are finding ways to leverage both models, using dropshipping to test products and expand their catalog while utilizing 3PL services for their proven best-sellers.

As competition in ecommerce intensifies, the businesses that will thrive are those that strategically employ the right fulfillment approach for each product and stage of growth, creating a seamless customer experience regardless of the back-end logistics involved. Understanding the nuances of both dropshipping and 3PL services, and how they can work together, provides a significant competitive advantage in today’s dynamic ecommerce landscape.

Frequently Asked Questions

What is Dropshipping?

Selling products without physical inventory. When an order is placed, the seller creates a Purchase Order for the supplier to ship to the customer directly.

What is a 3PL?

3PLs, (third-party logistics) are warehouses that do not belong to the seller, but the seller uses to store and distribute inventory.

What are the differences between dropshipping and using a 3PL?

Dropshipping means taking orders with no inventory, which can have issues if the supplier has inventory issues. Dropshipping comes from the supplier, which can lead to further distances, and thusly, more costly shipping. 3PLs process orders quickly and effectively.

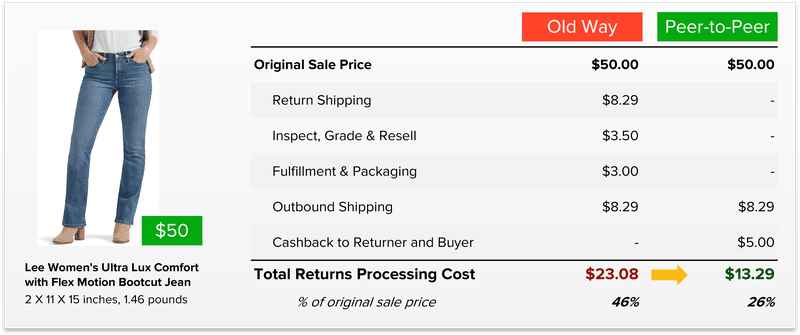

Up to 64% Lower Returns Processing Cost