Best 3PL for Small Business: A Complete Guide to Third-Party Logistics

Last updated on February 28, 2025

In this article

25 minutes

25 minutes

- What is 3PL?

- Why Small Businesses Should Consider 3PL Services

- Key 3PL Services for Small Businesses

- Selecting the Right 3PL Partner

- Implementation Best Practices

- Types of 3PL Services

- Tailored Approach vs. One-Size-Fits-All

- Common Challenges and Solutions in 3PL Partnerships

- The Future of 3PL for Small Business

- Conclusion

- Frequently Asked Questions

Third-party logistics (3PL) providers have become vital partners for small businesses looking to compete in today’s market. Utilizing 3PL for small businesses can alleviate resource constraints and optimize supply chain management. As consumer expectations for fast shipping continue to rise and supply chain complexities increase, 3PL services offer small businesses the infrastructure and expertise needed to deliver exceptional customer experiences without massive capital investments.

What is 3PL?

Third-party logistics (3PL) refers to outsourcing logistics and fulfillment operations to a specialized company. These providers, often referred to as fulfillment companies, handle various aspects of the supply chain, including warehousing, inventory management, order fulfillment, shipping, and returns processing. Essentially, 3PLs enable small businesses to focus on their core competencies while experts manage the complex logistics of getting products to customers.

Why Small Businesses Should Consider 3PL Services

Cost Efficiency

For small businesses, building and maintaining in-house logistics operations requires significant capital investment, which can be mitigated by partially or fully partnering with fulfillment companies. Warehousing space, equipment, technology, and staff all represent fixed costs that can strain limited resources. 3PLs offer a variable cost model where businesses only pay for the services and space they use, converting fixed costs to scalable operating expenses.

This model is particularly advantageous during seasonal fluctuations when order volumes may spike temporarily. Rather than investing in year-round capacity to handle peak periods, businesses can leverage 3PL resources that expand and contract with demand.

Geographical Expansion

Small businesses often start by serving local markets but eventually seek growth through geographical expansion. Building fulfillment infrastructure across multiple regions is prohibitively expensive for most small operations. 3PLs with established networks allow businesses to position inventory strategically across the country or even globally, reducing shipping times and costs.

This distributed inventory model enables small businesses to offer competitive shipping options like two-day or next-day delivery that would otherwise be impossible without multiple warehouses.

Technology Access

Modern logistics requires sophisticated technology systems, including warehouse management systems (WMS), transportation management systems (TMS), and order management platforms. Quality 3PLs invest in advanced technology and integrate with popular ecommerce platforms and marketplaces.

These integrations provide small businesses with real-time visibility into inventory levels, order status, and shipping information; capabilities that would require substantial investment to develop independently. This also enables data-driven decisions about inventory placement, stock levels, and shipping methods.

Expertise and Best Practices

Logistics specialists at 3PLs bring valuable expertise that can help small businesses optimize their supply chain. From warehouse layout and pick-and-pack procedures to carrier selection and route optimization, 3PLs implement best practices developed across numerous clients and industries.

This knowledge can be particularly valuable when navigating complex shipping regulations, customs requirements, or specialized handling needs for certain products.

Key 3PL Services for Small Businesses

Warehousing and Inventory Management

3PLs provide secure warehousing with organized inventory systems, which are crucial for effective supply chain management. Professional warehouse staff manage receiving, storage, and inventory counting, while technology solutions track stock levels and locations. This visibility helps prevent stockouts and overstock situations.

Order Fulfillment

When customers place orders, 3PLs handle the entire fulfillment process:

- Picking items from warehouse shelves

- Packing orders securely with appropriate materials

- Preparing shipping labels and documentation

- Handing off to carriers for final delivery

Many 3PLs also offer value-added services like custom packaging, promotional inserts, gift wrapping, or product kitting.

Shipping Optimization

Fulfillment providers typically maintain relationships with multiple carriers and can negotiate better rates based on their aggregate shipping volume than a small business can compel. They can help small businesses select the optimal shipping method for each order based on cost, transit time, and service requirements.

Returns Management

Processing returns efficiently is crucial for customer satisfaction, and a quality fulfillment service can manage the entire returns process. 3PLs can manage the entire returns process, including:

- Receiving returned items

- Inspecting products for damage

- Restocking sellable items

- Processing refunds or exchanges

- Disposing of or refurbishing damaged goods

Reporting and Analytics

Quality 3PLs provide detailed reporting on key performance indicators (KPIs) like order accuracy, shipping times, inventory levels, and return rates. These insights help small businesses identify improvement opportunities and make data-driven decisions.

Selecting the Right 3PL Partner

Choosing the right third-party logistics provider is a critical decision that can significantly impact your small business’s operational efficiency, customer satisfaction, and bottom line. The selection process should be approached methodically, with careful consideration of both your current requirements and future growth plans.

Assess Your Needs

Before approaching potential 3PL partners, small businesses should conduct a thorough internal assessment of their logistics requirements. Start by analyzing your order volume and patterns, including daily averages, weekly fluctuations, and seasonal peaks. Understanding these patterns helps identify a 3PL with the capacity to handle your business during both normal operations and peak periods without service degradation.

Handling Requirements: Examine your product characteristics in detail, considering dimensions, weight, fragility, and any special handling requirements. Products that require climate control, have hazardous materials classifications, or need special security measures will narrow your field of potential partners to those with appropriate capabilities. Take inventory of items requiring batch tracking, expiration date management, or serial number tracking, as these needs will influence your technology requirements.

Geographic Distribution: The geographic distribution of your customer base plays a crucial role in 3PL selection. Map out where your customers are located and analyze what percentage fall within various shipping zones. This analysis will help determine whether you need a single fulfillment center or multiple locations to meet customer delivery expectations. Consider both your current market footprint and areas where you plan to expand in the near future.

Technology Integration: Technology integration capabilities are increasingly important in the modern supply chain. Document your current technology ecosystem, including ecommerce platforms, inventory management systems, and order processing software. The right 3PL partner should offer seamless integration with these systems to provide real-time inventory visibility, order status updates, and comprehensive reporting. Consider whether you need customer-facing features like branded tracking pages or specialized reporting for your business analytics.

Budget: Budget constraints inevitably influence your 3PL selection. Beyond comparing basic rate cards, consider the complete financial picture, including implementation costs, minimum monthly commitments, peak season surcharges, and potential hidden fees. Evaluate your preferences for fixed versus variable costs and determine what cost-per-order metrics would make outsourcing to a 3PL financially advantageous compared to in-house fulfillment.

Growth Projections: Finally, factor in your growth projections when selecting a 3PL partner. Consider not just order volume increases but also how your business might evolve; whether through new product lines, additional sales channels, or expansion into new geographic markets. The ideal 3PL partner should be able to accommodate your growth without requiring you to switch providers as your business scales, which can be disruptive and costly.

Evaluate Provider Capabilities

When researching potential 3PL partners, begin by examining their warehouse network relative to your customer base. The strategic location of fulfillment centers can dramatically impact shipping costs and delivery times. Evaluate not just the geographic positioning but also the facilities themselves; their size, security measures, cleanliness, and technological sophistication. Ask about operational hours, including weekend processing capabilities and cut-off times for same-day shipping, which can be critical for meeting customer expectations.

Technology systems and integration capabilities have become differentiating factors among 3PL providers. Beyond basic warehouse management systems, look for advanced features like automated inventory alerts, exception management, and comprehensive reporting dashboards. Discuss integration methods, whether through APIs, EDI connections, or pre-built integrations with popular ecommerce platforms. Request demonstrations of their technology and ask about implementation timelines and support during the onboarding process.

Experience with similar products or businesses should weigh heavily in your decision. A 3PL that understands the unique requirements of your industry will anticipate challenges and implement appropriate solutions without extensive guidance. Ask for client references within your industry and inquire about their retention rates for businesses similar to yours. A provider with relevant expertise can offer valuable insights and best practices specific to your product category.

Carrier relationships and shipping options directly impact your ability to meet customer delivery expectations. Evaluate the breadth of a 3PL’s carrier network, including major national carriers, regional options, and specialized services. Ask about their negotiated rates and how these discounts are passed along to clients. Consider whether they offer strategic services like zone skipping or consolidation programs that could reduce your shipping expenses. Their approach to carrier management, including performance monitoring and contingency planning for service disruptions, reveals much about their operational sophistication.

Scalability is essential for growing businesses. Discuss how the 3PL handles volume fluctuations, both predicted (like holiday seasons) and unexpected (such as viral product success). Inquire about their capacity planning process and staffing model for peak periods. Review their contractual flexibility, including minimum commitments, storage space adjustments, and expansion possibilities. The right partner will offer room to grow without overly restrictive terms that penalize growth or changing business needs.

Value-added services can differentiate 3PL providers and offer convenience beyond basic pick, pack, and ship operations. These might include kitting and assembly, custom packaging, gift wrapping, monogramming, or product customization. Returns management capabilities are increasingly important in ecommerce, so evaluate their reverse logistics processes, including inspection procedures, disposition options, and restocking efficiency. For specialized products, confirm they have appropriate certifications or handling protocols, whether for hazardous materials, temperature-sensitive items, or high-value merchandise requiring enhanced security.

By thoroughly assessing your needs and methodically evaluating potential partners against these criteria, you’ll be positioned to select a 3PL provider that can support both your current requirements and future growth. Remember that the relationship with your 3PL is a partnership, not just a vendor arrangement. The right cultural fit, communication style, and mutual commitment to success are just as important as the technical capabilities and pricing structure.

Technology Compatibility

Ensure the 3PL’s systems can integrate smoothly with your ecommerce platform, inventory management software, and other business systems. Real-time data exchange between systems is essential for maintaining accurate inventory counts and order status information.

Pricing Structure

Understand how the 3PL charges for services. Common pricing components include:

- Storage fees (typically per pallet, bin, or square foot)

- Order fulfillment fees (per order or per item)

- Special project fees (receiving, returns processing)

- Minimum monthly charges

- Onboarding or setup fees

Compare total costs rather than individual line items, as pricing structures vary widely between providers.

Implementation Best Practices

Starting with a new 3PL is particularly harrowing for a small business. Here are some best practices to help make the transition as smooth and pain-free as possible.

Start With a Pilot

Rather than transferring all fulfillment operations immediately, consider starting with a subset of products or a specific geographic region. This approach allows you to test processes and integration points before full-scale implementation.

Develop Clear SOPs

Work with your 3PL to develop standard operating procedures (SOPs) that define responsibilities, communication protocols, and performance expectations. Document handling requirements for different products, quality control procedures, and exception management processes.

Plan for Seasonal Variations

Discuss how your 3PL will handle peak periods well in advance. Understand their capacity limitations and additional costs that may apply during high-volume periods like Black Friday or holiday seasons.

Establish KPIs and Regular Reviews

Define key performance indicators (KPIs) that align with your business objectives, such as order accuracy, on-time shipping, inventory accuracy, and returns processing time. Schedule regular reviews to evaluate performance against these metrics.

Types of 3PL Services

Third-party logistics (3PL) companies offer a wide range of services to help businesses manage their supply chain and logistics operations. These services are designed to streamline processes, reduce costs, and enhance customer satisfaction. Here are some common types of 3PL services:

- Order Fulfillment Services: 3PL providers handle the entire order fulfillment process, from receiving and storing inventory to picking, packing, and shipping orders to customers. This comprehensive service ensures that orders are processed efficiently and accurately, leading to timely deliveries and happy customers.

- Inventory Management: Effective inventory management is crucial for avoiding stockouts and overstock situations. 3PL companies manage inventory levels, track stock movements, and provide real-time inventory reports. This helps businesses optimize their inventory levels, reduce carrying costs, and ensure that products are always available when customers need them.

- Fulfillment Centers: 3PL providers operate fulfillment centers, which are specialized warehouses that store inventory and handle order fulfillment operations. These centers are strategically located to reduce shipping times and costs, ensuring that products reach customers quickly and efficiently.

- International Shipping: Expanding into global markets can be challenging due to complex customs regulations and logistics requirements. 3PL companies provide international shipping services, including customs clearance, freight forwarding, and logistics management. This expertise helps businesses navigate international shipping complexities and reach customers worldwide.

- Returns Management: Handling returns efficiently is essential for maintaining customer satisfaction. 3PL providers manage the entire returns process, including inspecting and restocking returned items, and providing refunds or replacements to customers. This streamlined process ensures that returns are processed quickly and accurately.

- Freight Management: Managing freight operations can be complex and time-consuming. 3PL companies handle various freight services, including truckload, less-than-truckload, and intermodal shipping. They optimize routes, negotiate rates, and ensure that shipments are delivered on time and within budget.

- Warehouse Management: Efficient warehouse management is critical for smooth logistics operations. 3PL providers manage warehouse operations, including receiving, storing, and shipping inventory. They use advanced technology and best practices to ensure that warehouses operate efficiently and accurately.

By leveraging these 3PL services, small businesses can focus on their core competencies while experts handle the logistics, leading to improved operational efficiency and customer satisfaction.

Tailored Approach vs. One-Size-Fits-All

When it comes to 3PL services, a tailored approach is often more effective than a one-size-fits-all approach. A tailored approach involves working with a 3PL provider that understands the unique needs and requirements of your business and provides customized solutions to meet those needs.

A one-size-fits-all approach, on the other hand, involves working with a 3PL provider that offers a standardized set of services that may not be tailored to your specific business needs. This approach can lead to inefficiencies, increased costs, and decreased customer satisfaction.

Common Challenges and Solutions in 3PL Partnerships

Even the most carefully selected third-party logistics partnerships encounter obstacles. Understanding common challenges and implementing proactive solutions can help small businesses maintain productive relationships with their 3PL providers and ensure seamless operations for their customers.

Inventory Discrepancies

Inventory discrepancies between your internal records and your 3PL’s warehouse management system can create significant operational issues, from overselling products to unnecessary reordering. These mismatches typically stem from several root causes. Receiving errors may occur when shipments arrive at the warehouse with quantities that don’t match purchase orders or packing slips. Picking errors can happen when warehouse staff select incorrect items or quantities for orders. System synchronization delays between your ecommerce platform and the 3PL’s inventory management system can temporarily create discrepant records. Additionally, theft, damage, or misplacement within the warehouse can lead to physical inventory counts that don’t match digital records.

To mitigate these challenges, establish a comprehensive inventory management protocol with your 3PL partner. Implement regular cycle counting programs where portions of inventory are counted on a rotating basis rather than relying solely on annual physical inventories. This approach allows discrepancies to be identified and resolved before they become significant problems. Develop a formal reconciliation process that includes comparing your system’s inventory levels with the 3PL’s records on a weekly or monthly basis, investigating variances above an established threshold, and documenting adjustments with root cause analysis.

Consider implementing advanced inventory tracking technologies such as barcode scanning or RFID systems that reduce human error in the receiving and picking processes. Establish clear protocols for handling damaged or unsellable inventory, including immediate notification and documentation requirements. Finally, negotiate inventory accuracy guarantees in your service level agreement (SLA), with specific remediation steps if accuracy falls below agreed-upon thresholds.

Communication Gaps

Communication breakdowns between small businesses and their 3PL providers can lead to misaligned expectations, unresolved issues, and deteriorating service quality. These gaps often emerge during periods of high volume or staff changes, when regular communication patterns may be disrupted. Cultural differences between organizations, including communication styles and problem-solving approaches, can exacerbate these challenges. Additionally, unclear escalation paths can leave urgent issues unaddressed while they work through standard communication channels.

To establish effective communication, begin by creating a comprehensive contact matrix that identifies primary and backup contacts for various functions at both organizations, including operations, customer service, IT, and executive leadership. Document preferred communication methods for different scenarios and expected response times. Schedule regular performance review meetings, typically monthly or quarterly, to discuss key metrics, address recurring issues, and align on upcoming initiatives or volume forecasts.

Implement a shared digital workspace or portal where both teams can access real-time information, track ongoing issues, and document operational decisions. Define clear escalation procedures for urgent situations, including criteria for escalation, communication channels for different severity levels, and resolution timeframes. Consider embedding team members at each other’s locations during critical periods like new product launches or peak seasons to facilitate direct communication and rapid problem-solving.

Technology can bridge many communication gaps through automated alerts for exceptions, shared dashboards for performance metrics, and integrated ticketing systems for issue tracking. However, remember that technology should complement, not replace, human relationships. Invest time in building personal connections between team members at both organizations, possibly through periodic in-person meetings or virtual team-building activities.

Customer Experience Control

Many small businesses hesitate to outsource fulfillment operations due to concerns about losing control over the customer unboxing experience, which has become increasingly important in the ecommerce landscape. This apprehension is understandable; the moment a customer opens a package represents a critical touchpoint for brand impression and customer satisfaction. When fulfillment moves to a 3PL warehouse, business owners no longer personally oversee each package’s preparation, potentially leading to inconsistent presentation or missed opportunities for brand reinforcement.

To maintain control over the customer experience while leveraging 3PL efficiencies, develop detailed packing instructions that specify every aspect of order preparation. Create visual guides with photographs showing proper product orientation, tissue paper folding techniques, insert placement, and final package appearance. Document specific requirements for different order types, such as gift orders versus standard purchases. Review and update these instructions regularly based on seasonal changes, new products, or evolving brand standards.

Invest in high-quality branded packaging materials that elevate the unboxing experience. Custom boxes, tissue paper, tape, thank-you cards, and product information inserts all contribute to a cohesive brand presentation. Consider including unexpected delights like product samples, discount codes for future purchases, or personalized notes for repeat customers. While these materials increase costs slightly, they significantly enhance perceived value and brand loyalty.

Implement a quality assurance program with your 3PL that includes random sampling of packed orders before shipment. Some businesses arrange for photos of randomly selected packages to be shared daily, while others conduct periodic on-site audits at the warehouse to observe packing procedures firsthand. Mystery shopper programs, where you or team members place occasional orders through normal channels, can provide valuable insight into the actual customer experience.

Closely monitor customer feedback related to packaging and presentation through reviews, social media mentions, and direct customer service inquiries. Establish specific metrics for packaging-related issues and review these regularly with your 3PL partner. Create a dedicated feedback loop where packaging concerns can be quickly addressed through operational adjustments.

Remember that customer experience extends beyond the physical unboxing to include accurate shipping estimates, proactive communication about delays, and seamless returns processes. Work with your 3PL to ensure these elements are aligned with your brand standards and customer expectations. By treating packaging specifications as non-negotiable brand requirements rather than optional guidelines, you can maintain a consistent customer experience while benefiting from 3PL operational efficiencies.

The Future of 3PL for Small Business

The third-party logistics landscape is evolving rapidly, driven by technological advances, changing consumer expectations, and competitive pressures. Forward-thinking small businesses can gain significant advantages by partnering with 3PLs that are embracing innovative approaches to fulfillment and logistics management.

Micro-fulfillment Centers and Urban Logistics

Traditional warehouse networks with large, centralized facilities in suburban or rural areas are being supplemented by strategically placed micro-fulfillment centers in densely populated urban locations. These smaller facilities, often 10,000-30,000 square feet compared to traditional warehouses of 100,000+ square feet, position inventory closer to end consumers in metropolitan areas. By utilizing underused real estate like vacant retail spaces or basement areas of existing buildings, 3PLs can offer same-day or even two-hour delivery windows for small businesses that previously couldn’t compete with major retailers.

The micro-fulfillment model particularly benefits small businesses selling time-sensitive products like perishable goods, premium consumer electronics, or fashion items where immediate gratification drives purchasing decisions. These centers typically stock high-velocity SKUs rather than complete inventories, using sophisticated algorithms to predict which products should be positioned in each urban location based on local demand patterns. For small businesses, this creates opportunities to offer Amazon-like delivery speeds without the massive infrastructure investment that would otherwise be required.

As this trend accelerates, expect to see 3PLs offering tiered delivery options with corresponding pricing models, allowing your customers to choose between same-day, next-day, or standard shipping based on their urgency and willingness to pay. This flexibility enables small businesses to capture sales from both convenience-oriented and price-sensitive customer segments.

Robotics and Automation Advancements

Warehousing automation, once accessible only to large enterprises with massive volumes, is increasingly becoming available to smaller merchants through their 3PL partners. Collaborative robots (cobots) that work alongside human warehouse staff are being deployed for repetitive tasks like inventory movement, picking, and packing. Unlike earlier industrial robots that required segregated operation areas, these newer systems integrate safely into existing workflow patterns, enhancing productivity without requiring complete warehouse redesigns.

Autonomous mobile robots (AMRs) that transport items between picking stations and packing areas are reducing human walking time within warehouses, which traditionally accounts for up to 60% of the picking process. Pick-to-light systems guide warehouse workers to the correct locations and quantities using LED indicators, dramatically improving accuracy and speed. Automated storage and retrieval systems (AS/RS) maximize vertical space utilization, increasing storage density while improving picking efficiency.

For small businesses, these technological advances translate to faster order processing, higher accuracy rates, and ultimately, lower per-order fulfillment costs as their 3PL partners pass along efficiency gains. Additionally, these systems generate rich operational data that can inform inventory planning, product slotting, and warehouse layout optimizations. As labor costs continue to rise and skilled warehouse workers become harder to find, automation allows 3PLs to maintain service levels without proportional cost increases.

The coming years will likely see increasing personalization capabilities within automated environments, allowing for custom packaging, inserts, and even product configurations to be executed efficiently at scale. This development will be particularly valuable for small businesses seeking to maintain brand distinctiveness while leveraging standardized fulfillment infrastructure.

Sustainability Initiatives

Environmental consciousness is rapidly shifting from a nice-to-have feature to a business imperative as consumers increasingly factor sustainability into their purchasing decisions. Progressive 3PLs are implementing comprehensive sustainability programs that go beyond basic recycling to include carbon-neutral shipping options, energy-efficient facilities, and eco-friendly packaging alternatives.

Carbon-neutral shipping programs typically involve calculating the carbon footprint of transportation activities and then purchasing verified carbon offsets to counterbalance these emissions. Some 3PLs are transitioning their delivery fleets to electric vehicles for last-mile delivery or partnering with carriers that use alternative fuels for longer routes. At the warehouse level, investments in solar panels, LED lighting, motion sensors, and high-efficiency HVAC systems are reducing energy consumption and associated carbon emissions.

Packaging sustainability represents a particularly visible area of innovation. Biodegradable void fill materials, right-sized packaging that eliminates unnecessary space, and reusable shipping containers are becoming more common. Some 3PLs now offer packaging made from post-consumer recycled materials or innovative alternatives like mushroom-based packaging for cushioning products during transit.

For small businesses, aligning with environmentally conscious 3PLs offers multiple benefits. Eco-friendly practices can be highlighted in marketing materials and on product packaging, appealing to environmentally conscious consumers. Sustainable packaging often reduces dimensional weight charges from carriers, potentially lowering shipping costs. Additionally, as environmental regulations continue to evolve, working with compliant 3PLs helps insulate small businesses from potential regulatory challenges or consumer backlash.

Enhanced Returns Solutions

The returns process has evolved from an operational afterthought to a critical component of the customer experience and a significant driver of customer loyalty. Innovative 3PLs are developing comprehensive reverse logistics solutions that transform returns from a necessary cost center into a strategic advantage for small businesses.

At-home pickup services eliminate the need for customers to bring returns to shipping locations, significantly improving convenience. Some 3PLs have established partnerships with gig economy platforms or local courier services to provide scheduled pickup windows, mirroring the convenience of the original delivery experience. Mobile return processing, where drivers can inspect items and process refunds at the point of pickup, accelerates the customer’s financial resolution while reducing return shipping costs for items that don’t need to go back to the warehouse.

Instant refund capabilities, enabled by integration between 3PL systems and merchant payment platforms, allow customers to receive immediate credit upon initiating a return rather than waiting for the item to be received and processed at the warehouse. While this approach carries some fraud risk, advanced algorithms can assess return history and purchase patterns to determine eligibility for instant refunds.

Sophisticated 3PLs now offer multiple disposition paths for returned items based on condition, value, and restocking costs. These might include returning to available inventory, routing to refurbishment, donating to charity, liquidating through secondary markets, or environmentally responsible disposal. This triage approach maximizes recovery value while minimizing unnecessary handling.

For small businesses, these enhanced returns capabilities can transform a traditional pain point into a competitive advantage. Businesses can advertise hassle-free returns as a selling point, potentially increasing conversion rates for first-time buyers who may be hesitant to purchase without seeing products in person. The faster inventory recapture from efficient returns processing improves cash flow and reduces the risk of seasonal merchandise losing value before it can be restocked.

Data Analytics and Predictive Intelligence

The next frontier in 3PL evolution centers on transforming operational data into actionable business intelligence. Advanced 3PLs are developing sophisticated analytics platforms that provide small businesses with insights previously available only to large enterprises with dedicated data science teams.

Predictive inventory models analyze historical sales patterns, upcoming promotions, seasonal factors, and even external data like weather forecasts or social media trends to recommend optimal inventory levels across warehouse locations. These systems can identify slow-moving products before they become problematic and suggest redistribution of inventory to locations with higher demand.

Shipping optimization algorithms analyze delivery performance across carriers, routes, and service levels to recommend the most cost-effective shipping methods that still meet customer expectations. These systems can identify opportunities for zone skipping, carrier consolidation, or service level adjustments that reduce costs without impacting delivery timelines.

Customer behavior analytics examine purchase patterns, return frequencies, and geographic distributions to help small businesses better understand their customer base. These insights can inform product development, marketing strategies, and even website design to better serve customer preferences.

For small businesses, these analytical capabilities provide a significant competitive advantage without requiring in-house data expertise. By partnering with analytically sophisticated 3PLs, small merchants can make data-driven decisions about inventory investments, marketing initiatives, and product development. This intelligence-driven approach minimizes costly inventory mistakes and maximizes return on limited resources.

As these trends continue to develop, small businesses that partner with forward-thinking 3PLs will gain access to capabilities previously reserved for large enterprises with substantial resources. The democratization of advanced logistics capabilities through 3PL partnerships is effectively leveling the playing field, allowing smaller merchants to compete on service and experience rather than simply on price or product.

Conclusion

For small businesses facing logistics challenges, 3PL partnerships offer a compelling solution. By outsourcing warehousing, fulfillment, and shipping operations, small businesses can achieve operational efficiencies, geographic reach, and service levels previously available only to larger enterprises.

The key to success lies in careful partner selection, clear communication, and ongoing performance management. With the right 3PL relationship, small businesses can focus on product development, marketing, and customer relationships while their logistics partner ensures products reach customers efficiently and cost-effectively.

As you evaluate whether 3PL is right for your small business, consider not just your current needs but your growth trajectory. The scalability and flexibility of 3PL services make them particularly valuable for businesses with ambitious expansion plans or those navigating the unpredictable early stages of development.

Frequently Asked Questions

What is a 3PL?

A 3PL (3rd Party Logistics) is a company that can handle warehousing and shipping on your behalf.

What is the Main Benefit of a 3PL for a Small Business?

Savings and scalability. 3PLs are a way for a small business to expand without having to shoulder the costs of new warehouses solely on their shoulders.

Do 3PLs Work Well for Small Businesses with Low Order Volumes?

Depending on the contract, 3PL outsourcing can still be worth it for small order volumes.

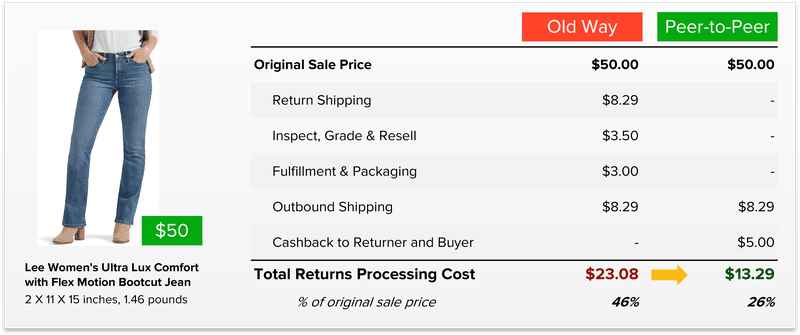

Up to 64% Lower Returns Processing Cost