Why eCommerce Sellers Today Need Next-Generation Shipping Software

Last updated on March 19, 2025

In this article

8 minutes

8 minutes

- The Changing Landscape of Ecommerce Shipping

- How Next-Gen Shipping Software Simplifies Ecommerce Fulfillment

- Boosting Warehouse Efficiency with Automation

- Cutting Costs and Maximizing Profitability

- Conclusion: Next-Generation Software is Critical to Winning in the New World

- Frequently Asked Questions

Key Takeaways:

- Legacy shipping software is outdated and inefficient in today’s ecommerce world.

- Next-gen shipping software automates fulfillment, reducing errors and improving delivery speed.

- Optimized order routing and packaging help businesses save money and maximize profitability.

- Warehouse automation boosts efficiency, helping businesses do more with fewer resources.

- Smarter carrier selection and real-time rate shopping eliminate unnecessary shipping expenses.

Ecommerce logistics have evolved dramatically in the past two decades, and with this shift, the tools that businesses use must evolve too. Ecommerce shipping software is a powerful tool designed to streamline and automate the shipping processes for online businesses. Choosing the right ecommerce shipping solution significantly enhances operational efficiency and customer satisfaction. Legacy software, however, built for a simpler time, can no longer keep up with the growing complexities of modern ecommerce shipping, making it essential to choose the best shipping software for your business. Rising customer expectations, increasing competition, and skyrocketing operational costs have made traditional fulfillment strategies obsolete.

Enter next-generation shipping software: a smarter, faster, and more cost-effective solution designed to streamline operations, optimize shipping processes, and drive profitability. In this pillar article, we’ll explore the four key areas where next-gen ecommerce shipping software is reshaping fulfillment and helping businesses thrive.

To help ecommerce merchants understand why traditional shipping software is no longer enough, we built a Next-Generation Shipping Software Guide consisting of 4 parts to highlight what has changed between the old world and the new world, how next-gen shipping software simplifies fulfillment operations, how it makes order fulfillment more efficient, and how it saves ecommerce businesses money:

- Ecommerce Shipping Challenges: The World Has Changed and Traditional Shipping Software is Not Enough

- Shipping Software for Ecommerce Fulfillment: The Next Generation of Shipping Simplified

- Next-Gen Warehouse Automation Software for Ecommerce: Fulfillment Efficiency

- Save Money With Ecommerce Shipping Software: Next-Gen Solutions

1. The Changing Landscape of Ecommerce Shipping

Two decades ago, ecommerce was a different world. Online Sellers operated on a single channel, faced minimal competition, and customers had lower expectations. Shipping was simple: businesses worked with a single carrier, operated from one warehouse, and didn’t have to worry about complex fulfillment logistics.

Fast forward to today, and the ecommerce landscape has changed dramatically:

- Sellers operate across multiple channels like Amazon, Walmart, and Shopify.

- Competition is intense, requiring fast, free shipping to stay ahead.

- Customers expect 1-2 day delivery, forcing Sellers to distribute inventory across multiple warehouses.

- Carrier rate increases (GRIs) have made it more expensive to ship orders profitably.

With this growing complexity, businesses can no longer rely on legacy shipping software that lacks automation, intelligent decision-making, and scalability. Next-gen ecommerce shipping software is purpose-built for today’s challenges, offering automated order routing, real-time carrier rate shopping, and seamless multi-channel integration to optimize fulfillment workflows.

2. How Next-Gen Shipping Software Simplifies Ecommerce Fulfillment

Modern ecommerce fulfillment is no longer just about printing shipping labels; it’s about optimizing every aspect of the supply chain. Multi-carrier shipping software allows businesses to compare rates and select the best carrier for each shipment, optimizing delivery times and reducing costs. Next-gen shipping software simplifies fulfillment in three key ways:

Automated Order Routing & Carrier Selection

Traditional shipping software relies on manual rule-setting, requiring Sellers to configure automation workflows manually. This process is prone to errors and inefficiencies. Next-gen shipping software, like Cahoot, automates order routing by:

- Analyzing warehouse locations, inventory levels, and carrier options to pick the best fulfillment center.

- Selecting the most cost-effective shipping label in real-time.

- Minimizing errors and eliminating manual decision-making through intelligent automation.

Seamless Multi-Warehouse and Multi-Channel Fulfillment

Today’s ecommerce businesses must operate across multiple fulfillment centers while managing orders from different marketplaces. Legacy shipping tools struggle to coordinate fulfillment effectively. Next-gen solutions:

- Sync orders from multiple sales channels (Amazon, Walmart, Shopify, etc.) automatically.

- Ensure inventory is updated in real-time to prevent overselling.

- Provide centralized tracking so businesses and customers stay informed on shipment status.

Optimized Packaging for Cost Reduction

Shipping costs are a major concern, and incorrect packaging can lead to excessive dimensional weight fees. Next-gen software optimizes packaging by:

- Using AI-powered cartonization to select the smallest possible box.

- Minimizing wasted space to reduce shipping costs.

- Automating packing decisions, eliminating the need for warehouse workers to make manual judgments.

- Automating international shipping processes, such as customs documentation and tax calculations ensures the job is done right the first time and prevents costly re-work.

3. Boosting Warehouse Efficiency with Automation

Labor shortages and rising wages make it difficult for ecommerce businesses to scale using traditional warehouse management strategies. Next-gen shipping software maximizes efficiency by reducing the need for manual intervention:

Reducing Manual Labor

Legacy software often requires warehouse staff to manually verify orders, select boxes, and compare carrier rates. With next-gen software:

- Workers spend less time on repetitive tasks, reducing operational costs.

- Shipping label generation is fully automated, cutting down processing time from hours to minutes.

- Seasonal and part-time staff can quickly onboard without extensive training, thanks to intuitive, easy-to-use interfaces.

Real-Time Fulfillment Network Optimization

Unexpected delays such as warehouse disruptions, weather-related shipping slowdowns, or inventory shortages, can impact fulfillment speed. Next-gen software helps businesses adapt in real time by:

- Identifying the best alternative fulfillment center if one location is affected.

- Re-routing orders automatically to ensure deliveries remain on schedule.

- Reducing fulfillment downtime, keeping customers happy and operations running smoothly.

- Real-time inventory tracking ensures that stock levels are accurately maintained, preventing overselling and stockouts.

4. Cutting Costs and Maximizing Profitability

Ecommerce margins are tighter than ever, and reducing costs is critical to long-term success. Next-gen shipping software saves businesses money in three crucial ways:

Lowering Discounted Shipping Rates with Intelligent Rate Shopping

Traditional software requires businesses to set up static rules, but these don’t always result in the cheapest shipping label. By leveraging advanced algorithms, businesses can secure the best shipping rate for each order, further reducing costs. Next-gen solutions:

- Compare carrier rates in real-time, ensuring Sellers get the best deal.

- Automatically adjust shipping selections based on weight, dimensions, and distance.

- Reduce the risk of overpaying for shipping fees with dynamic optimization.

Avoiding Hidden Fees and Cost Leakages

Many businesses unknowingly lose money due to inefficient fulfillment processes. Next-gen shipping software prevents cost leakages by:

- Eliminating unnecessary shipping surcharges through optimized package selection.

- Preventing human errors in box selection, reducing dimensional weight overcharges.

- Enhancing inventory tracking and distribution, ensuring products are stored in locations that minimize shipping costs.

- Effective inventory management ensures that products are stored in optimal locations, minimizing shipping costs and reducing the risk of overstocking.

Enabling Businesses to Do More with Fewer Resources

By automating labor-intensive tasks, businesses can reduce staffing needs and reallocate resources toward growth-driven initiatives. The benefits include:

- No need for dedicated shipping software teams to configure and maintain automation rules.

- Faster processing speeds, allow businesses to handle more orders with the same workforce.

- Improved scalability, making it easier to expand operations without increasing costs.

Why Next-Gen Shipping Software is a Game Changer

Ecommerce has evolved, and fulfillment operations must evolve with it. Legacy shipping software was designed for a different era; one with fewer channels, lower customer expectations, and simpler logistics. The modern landscape requires automation, intelligence, and flexibility to keep up with demand while staying cost-effective.

Conclusion: Next-Generation Software is Critical to Winning in the New World

We believe everything has changed in ecommerce. Amazon Prime has changed the industry in a manner comparable to how the iPhone changed society’s experience with, and access to, technology.

Prime transformed one aspect of ecommerce more than any other: shipping. However, this is the area where the least technological advancement has occurred in the industry. We believe legacy tools are costing Sellers time, money, and productivity on every order. In a world of competitive online marketplaces, sky-high customer expectations, and rising costs, Sellers have it extremely hard as it is. They don’t need technology adding to their list of worries. They need software that helps them compete and win, and selecting the best shipping solution is essential in this new world of ecommerce to enhance operational efficiency and customer satisfaction. When you choose shipping software that aligns with your business needs, you can significantly improve your operational efficiency and customer satisfaction.

The future of ecommerce fulfillment is here, and it’s powered by next-generation shipping software. By adopting these advanced solutions, businesses can streamline operations, improve customer satisfaction, and ultimately increase their bottom line. Such a tool must be capable of addressing some of the key challenges of the new world of ecommerce: simplifying operational complexity, providing efficiency and productivity gains for your team to free them up to focus on the things that matter most, and providing savings that restore margins in an intensely competitive environment. We believe our tool does exactly that.

We believe this tool can provide you with strategic and competitive advantages in today’s complex ecommerce industry. Are you ready to make the switch? If you’d like to learn more, check out our Next Generation Shipping Software Guide, Part 1: “Ecommerce Shipping Challenges: The World Has Changed and Traditional Shipping Software is Not Enough”.

Frequently Asked Questions

How can I reduce shipping costs for my ecommerce business?

Reducing shipping costs requires a multi-faceted approach:

- Negotiate rates with multiple carriers rather than relying on a single provider

- Consider using regional carriers for deliveries within specific areas

- Optimize packaging to reduce dimensional weight charges

- Implement zone skipping by shipping bulk orders to carrier hubs closer to final destinations

- Use shipping software that compares rates across carriers in real-time

- Offer local pickup options for customers in your area

- Consider flat-rate shipping for certain product categories

- Learn more

Who uses shipping software?

Shipping software has features that can benefit various clients, including individual Sellers, ecommerce brands, retailers, and courier service providers. Feature-rich software like Cahoot is autonomous and makes highly intelligent and scalable fulfillment and shipping accessible to retailers and brands of all sizes.

What is fulfillment optimization?

Fulfillment optimization is the process of determining the best options for sourcing and order fulfillment, which results in more efficient use of inventory and reduced costs.

How does warehouse automation software improve ecommerce fulfillment?

Warehouse automation software streamlines fulfillment by automating tasks such as order routing, shipping label generation, and inventory tracking. This reduces manual errors, increases processing speed, and optimizes carrier selection, ensuring faster and more cost-effective deliveries.

How does automated cartonization help reduce shipping costs?

Automated cartonization uses AI to determine the best packaging size for each order, reducing dimensional weight costs and preventing wasted space. This optimization leads to lower shipping fees and improved warehouse space utilization.

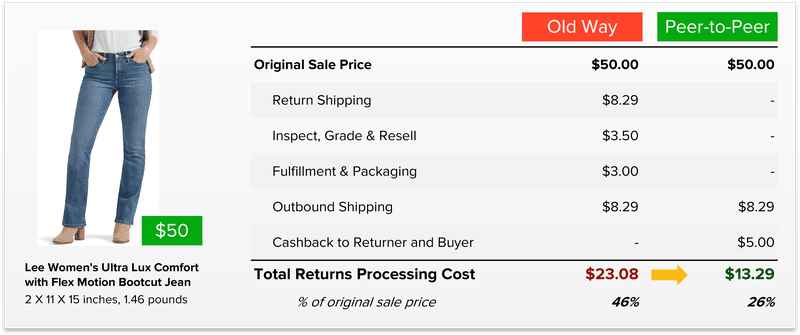

Up to 64% Lower Returns Processing Cost