Finding the Right 3PL Partner for Consumer Electronics Fulfillment | Cahoot

Last updated on February 28, 2025

In this article

9 minutes

9 minutes

- Understanding the Complexities of Consumer Electronics Fulfillment

- Why Choose a 3PL Partner for Consumer Electronics Fulfillment?

- Key Services Provided by 3PLs in the Electronics Industry

- Opportunities Created by Outsourcing Fulfillment

- Potential Drawbacks of 3PL Partnerships

- Choosing the Right 3PL Partner for Your Business

- Conclusion

- Frequently Asked Questions

In the fast-paced world of consumer electronics, businesses face a unique set of logistical challenges. High-value products, fluctuating demand, rapid product cycles, and complex global regulations create a landscape where efficient supply chain management isn’t just an advantage—it’s essential. Third-party logistics (3PL) providers offer a strategic solution, helping businesses navigate these complexities while unlocking new levels of efficiency, scalability, and customer satisfaction.

Outsourcing fulfillment to a 3PL can transform operational challenges into growth opportunities, but it also comes with challenges. In this article, we’ll explore the benefits, potential drawbacks, and strategic opportunities that 3PL partnerships bring to the table for consumer electronics sellers.

Understanding the Complexities of Consumer Electronics Fulfillment

The logistical requirements for fulfilling consumer electronics are complex. Products vary widely in size, fragility, and value—from compact smartphones to large home entertainment systems—each requiring specialized handling and secure packaging. Additionally, the sector is marked by unpredictable demand spikes, often driven by seasonal trends, new product launches, or market fluctuations.

One major challenge is inventory management. Overstocking ties up capital and increases warehousing costs, while understocking risks missed sales and dissatisfied customers. Accurate demand forecasting is difficult but critical, especially when navigating global supply chains prone to disruptions. Delays in shipments, whether from natural disasters or geopolitical events, can have costly ripple effects.

Returns management further complicates operations. Electronics have higher return rates than many other products due to defects, compatibility issues, or customer dissatisfaction. Handling returns efficiently—while minimizing costs and maintaining customer satisfaction—requires a refined reverse logistics process.

Aside from pure returns, electronics products involve hundreds or thousands of interlocking components, which need to be tracked for the purpose of recalling defective products or verifying products covered by warranty. Effective serial number tracking for each product is essential for effectively handling such issues when they inevitably arise, and has the added benefit of being useful for detecting counterfeit products as well.

With high-value products in transit and storage, the risk of theft or damage is significant. Last-mile delivery also presents challenges, as customers expect fast, reliable, and damage-free delivery, with any delays or mishandling potentially damaging brand reputation.

Complying with various regulations adds another layer of complexity. Consumer electronics often cross international borders, making them subject to diverse regulations, tariffs, and environmental guidelines. Failure to comply can result in fines, delays, or product recalls.

Why Choose a 3PL Partner for Consumer Electronics Fulfillment?

Partnering with a 3PL provider offers consumer electronics businesses a way to streamline their operations, reduce costs, and focus on core competencies like product development and marketing. Specialized 3PLs bring industry-specific expertise and the infrastructure needed to manage the unique challenges of electronics logistics.

One of the most significant benefits is cost efficiency. 3PL providers operate at scale, allowing businesses to tap into negotiated shipping rates, shared warehousing spaces, and optimized logistics networks. This not only reduces operational costs but also provides access to advanced technologies and automation without the need for heavy capital investment.

Efficiency is another major advantage. 3PLs offer end-to-end solutions—from inventory management and order fulfillment to packaging, kitting, and returns processing. Their experience in handling fragile and high-value products ensures that electronics are packaged securely and delivered intact. Moreover, advanced inventory management systems provide real-time tracking and data-driven insights, helping businesses maintain optimal stock levels and avoid costly stockouts or overstocks.

In the dynamic consumer electronics market, scalability is a critical factor. Demand can spike suddenly during product launches, sales events, or holiday seasons. A reliable 3PL can quickly scale operations to accommodate these fluctuations, ensuring that fulfillment remains smooth even during peak periods.

Customer satisfaction can also see a boost. Timely, accurate deliveries, combined with efficient returns management, help build trust and loyalty. Many 3PLs also offer value-added services like customized packaging, product bundling, and eco-friendly shipping options, enhancing the overall customer experience.

Key Services Provided by 3PLs in the Electronics Industry

A quality 3PL partner offers a range of services tailored to the specific needs of consumer electronics businesses. These services go beyond basic warehousing and transportation to provide comprehensive supply chain solutions.

Inventory Management is at the core of 3PL services. With advanced systems, businesses gain real-time visibility into stock levels, allowing for accurate forecasting, efficient replenishment, and reduced carrying costs. This level of transparency is crucial in managing the wide range of SKUs common in electronics.

Along with inventory management, order fulfillment represents the core service provided by a 3PL. 3PLs handle everything from picking and packing to shipping and last-mile delivery. They ensure that each product is securely packaged to prevent damage during transit, particularly important for fragile electronics.

3PLs can also provide valuable services outside of their core fulfillment and storage operations, however. Transportation and freight management is another area where they often excel. By leveraging their networks and expertise, they optimize shipping routes, manage freight costs, and ensure regulatory compliance across borders.

Returns management or reverse logistics is an area where many electronics companies struggle. 3PL providers streamline this process, managing everything from product inspections and refurbishments to restocking or manufacturer returns. Efficient returns handling not only reduces costs but also improves the customer experience.

Consumer electronics frequently have special packaging and kitting requirements, and many 3PLs offer such services to further increase their potential value to sellers. Electronics may require special packaging to prevent damage, and bundling related items is an even more common practice with electronics than with other goods. 3PLs handle these tasks with precision, ensuring that all components reach the customer in perfect condition.

Opportunities Created by Outsourcing Fulfillment

Outsourcing fulfillment to a 3PL opens doors to growth and innovation. One key opportunity is the ability to focus more on core business activities. By handing over logistics management, businesses can dedicate more resources to product development, marketing, and customer engagement.

Access to advanced technology is another major advantage. Many 3PLs invest heavily in automation, robotics, and AI-driven analytics, allowing their clients to benefit from these innovations without direct investment. This can lead to improved forecasting, smarter inventory management, and more efficient order processing.

As a result, global expansion becomes more attainable with the help of a 3PL. Many providers offer international shipping and have fulfillment centers across different regions, enabling businesses to reach new markets without the complexities of managing overseas logistics.

Sustainability efforts can also be enhanced through a 3PL partnership. Many providers prioritize eco-friendly practices, from optimized shipping routes that reduce carbon emissions to recyclable packaging options. For electronics companies looking to appeal to environmentally conscious consumers, this can be a significant selling point.

Potential Drawbacks of 3PL Partnerships

While the benefits of partnering with a 3PL are substantial, there are potential drawbacks to consider. One of the primary concerns is the loss of direct control over the fulfillment process. When a third party handles logistics, there’s an inherent reliance on their systems and processes, which can lead to issues if the 3PL fails to meet performance expectations.

Costs can also be a double-edged sword. While 3PLs offer economies of scale and negotiated rates, fees can add up, particularly if the partnership isn’t carefully managed. Businesses must thoroughly understand a provider’s pricing structure to avoid unexpected costs.

Additionally, integration challenges can arise—especially when aligning the 3PL’s systems with existing business operations. Ensuring seamless communication between platforms is essential for real-time tracking, inventory management, and customer service.

In short, not all 3PLs are created equal. Choosing the wrong partner can lead to delays, inventory mismanagement, or damage to high-value products. It’s crucial to select a provider with experience in the consumer electronics sector and a proven track record of success.

Choosing the Right 3PL Partner for Your Business

Selecting the right 3PL partner is a strategic decision that requires careful consideration. Start by evaluating your business’s specific needs. Are you looking for global reach or regional fulfillment? Do you need specialized services like kitting or returns management? Understanding your priorities will help narrow down potential partners.

Look for a provider with industry experience. Consumer electronics require careful handling, secure storage, and efficient reverse logistics. A 3PL with a history of success in this sector will better understand these demands.

Location and scalability are also key factors. A provider with fulfillment centers near your target markets can reduce shipping times and costs. Scalability ensures that the 3PL can grow with your business, accommodating spikes in demand during product launches or holiday seasons.

Finally, assess the provider’s technology capabilities. Real-time tracking, inventory visibility, and data analytics are critical for optimizing your supply chain and maintaining customer satisfaction.

Cahoot’s distributed fulfillment network provides an innovative solution to many of the problems encountered by electronics sellers seeking fulfillment partners. Our large warehouse network guarantees nationwide coverage and helps accommodate rapid growth or sudden volume spikes, removing much of the hassle from adapting to fluctuating market conditions. Our rigorous and selective vetting process for warehouse partners keeps defect rates low, while ensuring that electronics are handled with the specialized care and attention they demand.

Conclusion

In the competitive world of consumer electronics, efficient logistics can make or break a business. Partnering with a 3PL provider offers a pathway to streamlined operations, cost savings, and enhanced customer satisfaction. While there are potential risks, careful selection and strategic collaboration can turn logistics from a challenge into a competitive advantage.

By leveraging the expertise, technology, and global networks of specialized 3PL providers, electronics businesses can focus on what they do best—innovating and delivering cutting-edge products—while leaving the complexities of fulfillment in expert hands.

Outsourcing fulfillment isn’t just about simplifying logistics—it’s about positioning your brand for sustainable growth in an ever-evolving market. With the right 3PL partner, the possibilities are endless.

Frequently Asked Questions

How can a 3PL help protect high-value electronics from theft or damage?

Reputable 3PLs employ advanced security measures, such as surveillance cameras, restricted access zones, and tamper-proof packaging to prevent theft. They also implement specialized storage conditions, shock-resistant packaging, and quality control checks to protect delicate electronics from damage during handling and shipping, reducing costly returns due to damaged units.

Can a 3PL handle returns and refurbishments for consumer electronics?

Yes, many 3PL providers offer reverse logistics services, including returns processing, product inspection, refurbishment, and restocking. Some 3PLs can even integrate with manufacturers to facilitate repairs or certified refurbishments, helping businesses recover value from returned products.

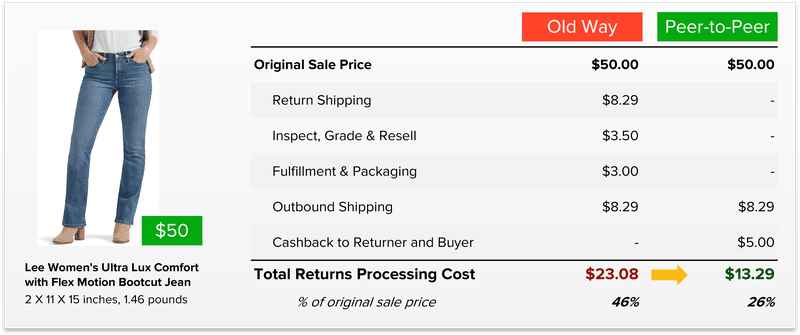

Up to 64% Lower Returns Processing Cost