Understanding Dimensional Weight Pricing

Last updated on March 5, 2025

As ecommerce continues to grow year-over-year, shipping costs remain one of the most critical elements affecting profitability. Dimensional weight pricing, often abbreviated as dim weight, is a crucial concept that every ecommerce business must grasp to avoid overpaying for shipping. This pricing model is designed to account for the space that a package occupies in relation to its actual weight. Whether you are a small business owner or managing logistics for a large ecommerce operation, understanding how dimensional weight works can help streamline your shipping processes and save on costs. In this article, we will break down what dimensional weight is, why carriers use it, and how to manage and minimize its impact on shipping expenses.

What is Dimensional Weight?

Dimensional weight is a pricing technique used by shipping carriers to charge based on the volume of a package rather than its actual weight. In traditional weight-based shipping models, customers pay according to the physical weight of their package. However, this approach doesn’t always account for packages that are large but lightweight—think of a large box filled with foam padding or bubble wrap, but containing only a small item inside. In these cases, the carrier is still using valuable space on their truck or aircraft, and thus, dimensional weight is applied.

To calculate dimensional weight, the carrier will use a formula that considers the dimensions of the package—its length, width, and height. For most carriers, this is usually done by multiplying these three dimensions together to find the volume of the package. That number is then divided by a standard “dimensional factor,” which varies depending on the carrier.

For example, if a box measures 12 inches long, 10 inches wide, and 8 inches tall, the volume would be 960 cubic inches (12 x 10 x 8). The carrier would then divide that number by the dimensional factor (let’s say it’s 139 for domestic ground shipping with FedEx or UPS), which results in a dim weight of 6.9 pounds (rounded up to the nearest pound, so 7 pounds). If the actual weight of the package is 3 pounds, the carrier would charge for the 7-pound dimensional weight instead of the actual weight, since it takes up more space.

Why Do Carriers Use Dimensional Weight?

Carriers adopted dimensional weight pricing to more accurately reflect the costs of transporting packages. Shipping is not only about the weight of the package—it’s also about how much space it occupies in a truck or airplane. The more space a package takes up, the less room there is for other packages. For shipping carriers, this means they can carry fewer goods, which ultimately reduces their efficiency and increases costs.

In recent years, the rise of ecommerce has led to an influx of smaller, lightweight items that are packaged in oversized boxes. While these packages are light in weight, they take up considerable space in transportation vehicles. As a result, carriers needed a way to ensure they were being fairly compensated for the space they were losing in favor of these packages. Dimensional weight provides a more accurate measure of the space a package occupies, which helps carriers balance costs, maximize capacity, and avoid inefficiencies.

Additionally, with the increasing popularity of express shipping and global commerce, international shipping has become more complex. In the case of air freight, the cost of moving goods is heavily influenced by the weight-to-space ratio. Shipping carriers must account for both weight and volume when determining prices to remain competitive while covering their expenses. Dimensional weight ensures that carriers are not subsidizing the cost of lighter, bulkier packages, which is crucial for maintaining profitability in a highly competitive and resource-intensive industry.

The Importance of the DIM Factor

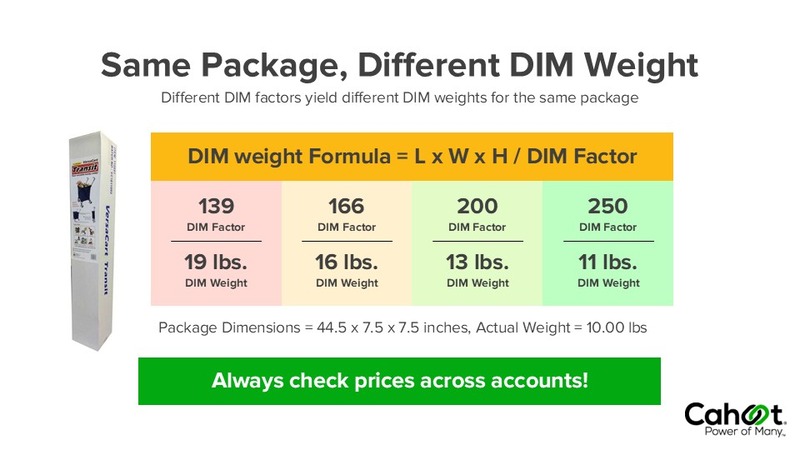

The “DIM factor” is a crucial element in dimensional weight pricing. This factor represents the “expected” ratio of a package’s volume (in cubic inches) to its weight. It plays a vital role in determining the dimensional weight of a package, and its value can vary depending on the carrier and the mode of transportation (ground, air, etc.). The DIM factor is a multiplier that converts the volume of the package into a weight equivalent. A lower DIM factor means that less volume per pound is “expected,” resulting in a higher dimensional weight, while a higher DIM factor leads to a lower dimensional weight for the same package.

Understanding the DIM factor is essential for ecommerce shippers because it allows them to better estimate shipping costs. As indicated above, different carriers may use different DIM factors, and knowing these differences can help make more informed decisions about which carrier to choose for a specific shipment. Additionally, some carriers may update their DIM factors periodically, so it’s important to stay informed about any changes to ensure you’re not caught off guard by unexpected cost increases.

Carriers can offer different DIM factors depending on the type of shipment. For example, express and international shipments might have a different DIM factor compared to standard ground shipping. This variation in the DIM factor means that dimensional weight can affect the total cost of shipping depending on how quickly the package needs to reach its destination and the method of transport being used.

Differences in DIM Factors Among Carriers and 3PLs

Different shipping carriers use slightly varied dimensional weight (DIM) calculation methods, primarily by adjusting the DIM factor, which influences how volume converts to weight. For example:

- FedEx, DHL, and UPS generally use a DIM factor of 139 for ground shipments within the U.S.

- USPS uses a factor of 166.

Additionally, different DIM factors may be used for air as opposed to ground shipments. This means that the same package might be billed at different rates depending on which carrier is used, making it crucial for shippers to compare options before selecting a service.

Some carriers also offer customized DIM factors for high-volume shippers or businesses that negotiate specific contracts. Additionally, certain services, such as USPS Priority Mail, do not apply dimensional weight pricing unless the package exceeds a particular size threshold (e.g., one cubic foot for domestic shipments). Understanding these variations can help ecommerce businesses strategically choose carriers and optimize packaging to minimize shipping costs.

In addition to differences in DIM factors among carriers, various 3PL services may use differing DIM factors when assessing fulfillment or inventory removal fees. Just as carriers use different DIM factors when calculating rates for different kinds of shipments, 3PLs may use different factors for domestic as opposed to international shipments, or for specific product classes. Be sure to confirm the DIM factors used by any 3PL service, including FBA, to accurately forecast shipping and fulfillment costs.

How to Minimize Dimensional Weight Costs

While dimensional weight pricing is a reality that ecommerce shippers must navigate, there are several strategies that can help minimize the associated costs. Here are some practical tips for reducing the financial impact of dimensional weight:

- Optimize Packaging: One of the most effective ways to reduce dimensional weight charges is to carefully consider the packaging you use. Shipping products in unnecessarily large boxes is a common mistake that results in higher shipping costs. Choose packaging that fits the product as closely as possible without wasting space. Nowadays, there is cartonization software that helps you decide what package to use to minimize excess space. If you can’t, you may also want to explore packaging materials like air pillows or foam inserts that can better protect your products while minimizing wasted space.

- Use Custom Packaging: If you consistently ship products that have irregular shapes or sizes, investing in custom packaging could be a smart move. Custom packaging allows you to reduce empty space within the box, which will help lower the dimensional weight.

- Consolidate Shipments: For businesses that ship multiple items, consolidating shipments into fewer packages can help lower dimensional weight charges. Instead of sending each item individually, combine them into a larger, more efficient package. This strategy helps spread out the dimensional weight across multiple products, reducing the overall cost of shipping.

- Take Advantage of Volumetric Pricing: Some carriers offer volume discounts or reduced dimensional weight charges for larger or heavier shipments. If you regularly ship large volumes, consider negotiating with carriers for better rates based on your shipment sizes. Shipping in bulk or negotiating long-term contracts with carriers can also provide discounts on dimensional weight charges.

- Compare Carrier Rates: As we’ve discussed, the DIM factor used can vary between carriers or between services for a given carrier. The exact same package can be billed as 18 pounds in one carrier account and 35 pounds in another. Therefore, it’s important to compare rates from different carriers to see who offers the most cost-effective pricing based on your packages’ size and weight.

- Monitor Your Shipments: Consistently tracking your shipping costs and reviewing your packaging practices can lead to ongoing savings. If you notice that certain shipments are disproportionately affected by dimensional weight pricing, reassess your packaging and look for ways to reduce the dimensions of those shipments.

- Choose the Right Service: When selecting a shipping method, choose the one that best fits the size and weight of your package. Ground shipping, for example, often has different dimensional weight rules than air freight, and express services can come with higher fees due to the faster delivery time. Take time to analyze your options before committing to a particular service.

Conclusion

Dimensional weight pricing is a necessary part of modern shipping, particularly for ecommerce businesses that regularly ship lightweight but bulky packages. Understanding dimensional weight, the importance of the DIM factor, and how to minimize costs can significantly improve your bottom line. By optimizing packaging, choosing the right carrier, and staying informed about changes in pricing, you can effectively navigate dimensional weight charges and keep your shipping expenses in check. In the competitive world of ecommerce, small adjustments to your shipping strategy can lead to big savings, ultimately helping you offer more competitive pricing and enhancing your customers’ satisfaction.

Fortunately, Cahoot is here to help. Our state-of-the-art shipping software is able to integrate across all major sales channels and compares rates across carriers to automatically select the most cost-effective options to meet your delivery requirements. Our nationwide network of warehouses ensures that, whatever your product and wherever your customer base, we are able to accommodate your specific fulfillment needs. Our proven solutions can help small businesses scale into established players, provide needed savings to sellers seeking to remain competitive, or find the best shipping solutions for bulky or hard-to-ship products. Whatever blockers are keeping your business from reaching its potential, Cahoot is here to help.

Frequently Asked Questions

Why is dimensional weight used by carriers?

Dimensional weight is used to account for the space taken up by a package as well as its weight. This kind of pricing has long been used for services like air freight, where space is at a premium and must be accounted for. With the explosion of ecommerce in the late 2000s and early 2010s, the major carriers began to apply dimensional weight pricing to ground shipments around 2015, to ensure that limited space in freight and delivery trucks is used efficiently.

Why do DIM factors differ between carriers or services?

Different carriers use varying DIM factors to align their pricing models with their specific operational costs, transportation methods, and target markets. The DIM factor represents the volume that equates to one pound of billable weight, and adjusting the factor allows carriers to balance space utilization and profitability. A lower DIM factor results in a higher dimensional weight, meaning shippers are charged more for bulky but lightweight packages. Conversely, a higher DIM factor allows for more generous volume-to-weight conversions, reducing costs for shippers.

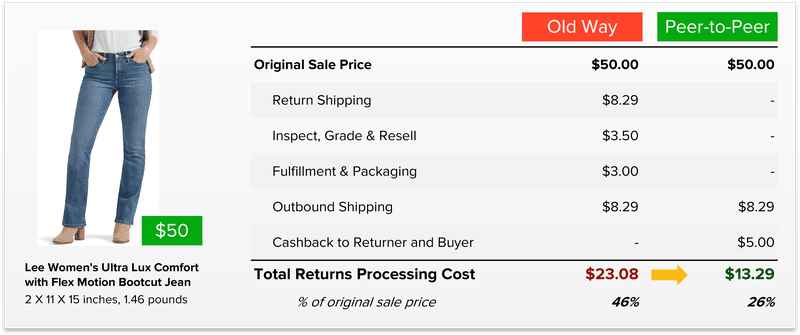

Up to 64% Lower Returns Processing Cost

10 minutes

10 minutes