3PL Fulfillment Pricing Comparison: Ecommerce Order Fulfillment: Peer-to-Peer Network vs Traditional 3PL

Last updated on February 14, 2025

In the era of online marketplaces, most eCommerce merchants and brands find themselves at the mercy of order fulfillment solutions operated by the powerful corporations who act as gatekeepers for these platforms – for example, Fulfillment By Amazon and Walmart Fulfillment Services. Each platform requires merchants to send inventory to their warehouses and follow their unique policies and requirements. All of them also come with their respective fees and surcharges.

Sellers seeking a better deal have often turned to Third Party Logistics Providers (3PLs). They do so with the ambition of not just regaining control and autonomy over their logistics, but also boosting their profits. Fulfillment companies often adjust their pricing models based on order volume, storage, and shipping factors, which can include volume discounts, providing additional savings to the seller.

The problem, however, is that the vast majority of 3PLs operate from an extremely limited number of locations – hampering the seller from being able to offer customers the free, fast shipping experience that they now expect and demand. To solve this problem, a disruptive, radically different strategy is needed – a peer-to-peer order fulfillment network.

While merchants have worked with traditional 3PLs, a peer-to-peer network is an entirely new idea. Those merchants who have used traditional 3PLs are often unaware of their pros and cons. Far fewer are aware of how they compare to a peer-to-peer network. In this article, we take a deep dive, looking at every factor that influences a seller’s choice of fulfillment partner, and compare traditional 3PLs to peer-to-peer networks on each of them. We highlight how a Peer-to-Peer network can offer significant advantages compared to working with legacy 3PLs.

Cost

Traditional 3PL Fulfillment Services – What Do They Have in Common With Traditional Hotels?

Think of a time when you stayed at a boutique, traditional hotel – are you struggling to find or remember when you last did that? In the era of Airbnb, these single-location hotels have lost significant market share.

Why is that?

The reason is not competition – that there is a segment of travelers looking for a more economical, boutique experience compared to staying at a large hotel chain like Marriott or Hilton. The reason is that these traditional hotels are asset-heavy businesses that have no economies of scale. Because they primarily operate from a single location that they rent or own, they are significantly prone to cost pressures driven by land availability, rental rates, and staffing.

All this has meant that a marketplace model with a vast network, such as Airbnb (almost anyone can rent out a space), offers significant advantages to travelers that traditional hotels cannot hope to match.

What if we told you a traditional 3PL is exactly like these hotels?

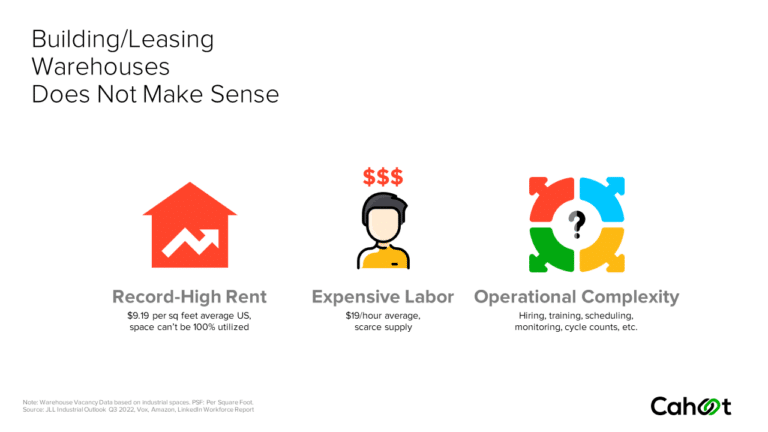

A traditional 3PL usually operates from an extremely limited number of locations (2-3 at the most). This provides them with little to no economies of scale. They are also asset-heavy businesses that rent or own their properties. This is compounded by the fact that staff in the warehouse now expect to be paid $19 / hr. With multiple players, such as Walmart and Target, setting up fulfillment centers to deliver their eCommerce orders, traditional 3PLs must pay people more if they are to staff their warehouses. This is also a cost pressure that has to be ultimately absorbed by the merchants who work with them.

Additionally, the surge in e-commerce has significantly increased warehousing costs. The demand for warehouse space and labor has skyrocketed, leading to higher prices and intensified competition within the third-party logistics industry. Traditional 3PLs are particularly affected by these rising warehousing costs, which further strain their ability to offer competitive pricing.

Peer-to-Peer – What do Cahoot and Airbnb Have in Common?

Airbnb’s business model is asset-light – their idea is simple but powerful – anyone that has a spare room at their house that they don’t use can monetize it.

This two-sided marketplace model generates network effects, with millions of customers (property owners and travelers) interacting to ensure the platform offers competitive prices constantly. We have a similar idea for the future of eCommerce – rather than everyone building more warehouses as part of their own private, isolated networks, what if we optimized what’s already available?

Cahoot’s peer-to-peer network aims to unlock the potential of over 2 million retailers with their own warehouses. Any merchant with excess capacity in their warehouses can monetize it by becoming a fulfillment partner for Cahoot.

Our two-sided marketplace model generates network effects, with numerous businesses (sellers and fulfillment partners) interacting to drive prices downward. Just like Airbnb has a massive spread of listings, our model provides us with a vast network of strategically located warehouses across the country. And just like them, we’re more economical than the previous solutions customers used.

Quality

Traditional 3PL – “Fast Shipping or Low Shipping Costs? Pick One”

With the limited number of locations these traditional 3PLs operate from, it becomes near impossible for them to cover the country through economical ground shipping in under two days.

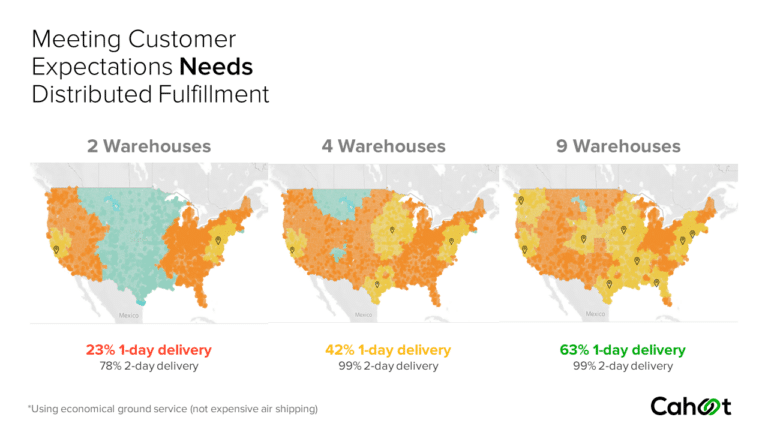

Based on our research, inventory needs to be spread across at least 4 strategic locations if a merchant is aiming for 2-day delivery to the entire contiguous United States (the lower 48 states). If the brand aims for 1-day delivery, it requires nine strategic locations.

When we talk about ‘strategic’ location, we mean it – a location is only strategic if it is located near a major population center. Suppose you’re a brand in the Midwest. In that case, it makes no sense to get excited about saving costs on inbounds by working with a traditional 3PL in Chicago, IL, when most of your orders might be coming from Southern California! Great candidates for strategic locations include New York, Chicago, and Southern California, as examples.

Most traditional 3PLs do not have warehouses at strategic locations – forcing their customers to decide whether to use economic ground services (but not meet the customer expectation for fast delivery) or incur extremely high costs by providing fast delivery through air shipping.

Peer-to-Peer – “Fast Shipping and Low Shipping Costs – Get Them Both.”

A Peer-to-Peer Fulfillment Network has a vast network of strategically located warehouses nationwide. With such a network, it is possible to cover the entire country through ground shipping in under two days. This makes it possible to meet the customer’s expectation for fast shipping while using economical services.

Many sellers might face hefty fees with platform-specific fulfillment services, such as Fulfillment By Amazon (FBA) for Amazon and Walmart Fulfillment Services (WFS) for Walmart. Merchants have no viable alternative because the only way traditional 3PLs can hope to offer the delivery speeds customers are used to is by using expensive air shipping. As no seller is willing to take a margin hit that deep, they are stuck with fulfillment services run by the marketplaces themselves.

With a Peer-to-Peer network, you do not have to make an either-or decision – you get the best of both worlds – providing both your business and your customers with benefits. Our network offers cost savings that boost your bottom line while also improving the experience your customers have.

Service Levels

Traditional 3PLs – Struggle to Offer The Bare Minimum

Traditional 3PLs just about get the basics done (with a lot of huffing and puffing and seller pain) – receiving your inbounds, picking, packing, and shipping your orders out the door on time. If you’re trying to handle additional requirements – such as operating the warehouse, arranging for carrier pickups, or fulfilling orders on the weekends, you’re likely out of luck.

The problem is that these ‘additional’ requirements are now becoming table stakes as this is what programs like Amazon Seller Fulfilled Prime expect. Additionally, customers expect their orders faster and faster, meaning that doing the basics alone may no longer be enough even to stay afloat.

Those aiming to compete with Amazon, including large retailers like Walmart, are realizing they must offer customers Prime-like experiences. Walmart’s shipping standards are also challenging – products with 2 and 3 day delivery speeds are ranked higher in search results, win the buy box more often, and see higher conversion rates. Sellers are also expected to ensure that they deliver 95% or more of orders within the promised time to customers.

Many of these 3PLs may also be unable to offer late cut-off times. Late cut-off times allow for carrier pickups and scans to occur the same day, meaning more of your customers will receive their orders in 1 or 2 days.

Perhaps most worryingly of all, customer support can often be erratic, unreliable, or slow to respond. Shipping and order fulfillment is a crucial part of your business operations. Lengthy resolution items can mean significant outages and downtime for your company.

Peer-to-Peer – Meet and Exceed the Gold Standard for Order Fulfillment

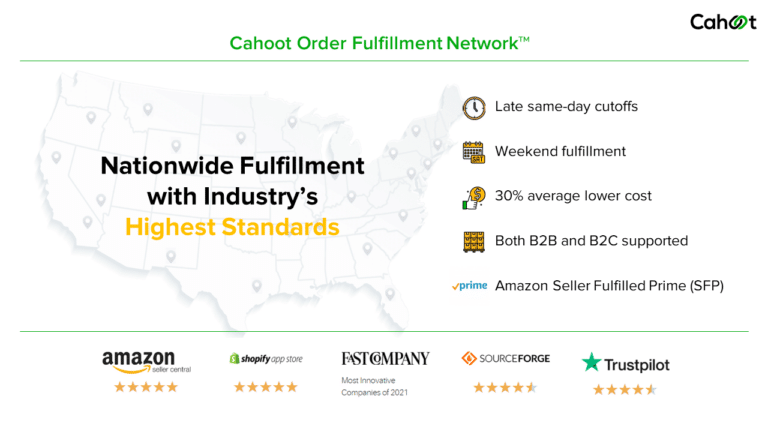

With Cahoot’s peer-to-peer network, you don’t just have to settle for the basics. We help sellers on Amazon meet and surpass the demanding criteria of the Seller Fulfilled Prime (SFP) program. The SFP program’s requirements are arguably the most challenging in the industry. Any merchant who can meet and surpass them has an excellent order fulfillment strategy in place.

We support warehouse operations, carrier pickups, and delivery on the weekends. We also offer late cut-off times, ensuring that you can increase the proportion of customers whom you service with 1- and 2-day delivery.

Our US-based customer support team is also ready and responsive to any of your questions. We know that eCommerce order fulfillment is complex, and things don’t always go as planned. What’s crucial is ensuring that those issues are addressed quickly, getting your business back on track. With our team, you can count on minimum downtime.

Technology

Traditional 3PL Fulfillment Providers Try to Handle Fulfillment Without Tailormade Tools

Many traditional 3PLs solve just one piece of the problem – the task of order fulfillment itself. Most of them fail to provide customers or their employees with the shipping software technology needed to speed up order fulfillment at scale.

The technology that most traditional 3PLs deploy is not much more advanced than what a micro-shipper fulfilling their orders on their own might be using.

Even if traditional 3PLs deploy technology, it tends to be legacy software, like ShipStation. Such tools require constant human intervention and oversight. For example, for every single customer order that is received, a tool like ShipStation requires staff to compare rates across different fulfillment locations and carrier services, manually identifying the cheapest option to pick.

Such systems mean that an enormous amount of time is wasted every single day by employees simply rate-shopping for shipping labels when they could be engaged in higher-order work.

For other workflows like keeping track of inventory, traditional 3PLs deploy similarly clunky, inflexible software incapable of meeting today’s needs. This runs the risk of accepting customer orders on SKUs that are out of stock, leading to canceled orders and unhappy customers. Unfortunately, your customers aren’t going to blame your 3PL’s poor technology when there are issues with their deliveries – they’re going to point the finger at you.

Peer-To-Peer – Scale Order Fulfillment with Purpose-Built Software

While our peer-to-peer network provides nationwide coverage, our next-generation shipping software supercharges productivity and accelerates order fulfillment.

For every order received, Cahoot’s software can intelligently compare multiple warehouse locations and shipping services, instantly determining the most economical shipping label that meets customer delivery promises.

Our software is designed and purpose-built from the ground up to excel at scale. When your order volumes surge, manually printing shipping labels can be a massive source of inefficiency. With Cahoot, all your shipping labels are ready to print in one click – dramatically speeding up fulfillment and freeing up staff to concentrate on higher-order work.

Our technology comes with other intelligent features – such as optimizing packaging choices for Multi-Line, Multi-Quantity (MLMQ) orders, as well as intelligently keeping track of inventory decrements. Color-coded alerts on our dashboard provide merchants with real-time visibility into dipping inventory levels. This allows for proactive decision making to accelerate sales, rather than scrambling to react too late.

Redundancy and Backup

Traditional 3PL – Highly Vulnerable to Single Point Failures

eCommerce order fulfillment is not an easy thing, and there are potentially many things that can go wrong – such as 3PL delays with receiving your inventory, damages to inventory in transit, misplaced inventory, or carrier errors.

There are also things for which it is difficult to account for – such as unexpected, extreme weather events that disrupt carrier operations.

While you can strategize to minimize or avoid some issues, others are simply out of your control. Unfortunately, this is where a traditional 3PL is highly vulnerable. When you operate from a single location, an outage in that location can be catastrophic. Your entire order fulfillment operations come to a grinding halt, putting your sales on pause. Worse, customer complaints will surge, resulting in lots of negative reviews and refund requests.

Customers today may not be forgiving even of circumstances outside your control, such as weather events – they ask a pertinent question, “Why weren’t you prepared with an alternative strategy?”

One minor issue at your 3PL can quickly snowball into a disaster for your brand reputation and customer loyalty. The only option sellers have is to find fulfillment partners whose solutions come with excellent risk mitigation, ensuring that orders reach customers no matter what.

Peer-To-Peer – Always Lights On For Your Business

A network of warehouses in different locations ensures that you’re inherently much more likely to keep your business operations constantly running smoothly.

You’re de-risked on multiple dimensions – if there’s terrible weather in 1 location, you can still fulfill orders from another warehouse. If there are issues with a carrier over there, you can ship from another location. If there’s an outage there….you get the idea.

This ensures that you’re constantly selling and customers are constantly getting their orders. They may also really appreciate how your business is always ready to serve them, no matter the circumstances. Unexpected, adverse circumstances don’t result in angry customers and negative reviews when working with Peer-to-peer fulfillment networks, they’re just another opportunity to continue selling and keep providing your customers a great experience.

Scalability

Traditional 3PL – Works Initially, But Stumbles at Scale

Going back to our earlier example, let’s say you’re a brand starting out in the Midwest, and you found a great traditional 3PL in Chicago, IL. You’re thrilled because your geographical proximity to them means that you’ll be saving a lot on inbound freight costs (sending your inventory to their warehouse on a truck).

In your first few days, most of your customers are your friends, who spread the word about your brand to their circles. Most of your orders tend to come from the Chicago area and Michigan – things are working well with the traditional 3PL. You can service your customers with fast delivery while using economical ground shipping.

At some point, your brand surges in popularity, and you start receiving orders nationwide – you’re thrilled and can already imagine the cash registers ringing! However, after an initial surge, you soon see very few orders coming in. After doing some investigation, you discover that your 3PL’s inefficiencies are costing you – customers in Southern California are receiving their orders far too slowly. Worst of all, knock-off listings on the Amazon marketplace have seized on your idea, and are now winning against you because they’re offering customers faster shipping. You also see a surge of refund requests, from customers who are unhappy with the time it’s taking for their orders to arrive.

Traditional 3PLs are ill-equipped to deal with spikes in order volume that happen naturally as you scale. These companies don’t become an enabler of your growth; they can be just the opposite – a bottleneck that slows you down.

The problems with traditional 3PLs mount at the worst possible time – once you start seeing orders come in from Southern California, let’s say you identify another fulfillment partner in Los Angeles. Now you have two contracts, each with its own pricing structure. There are 2 different SLAs for order fulfillment and you have to pick which location each of your orders is routed to, all on your own. Managing these two 3PLs can completely consume your bandwidth, overtaking your focus on the activities that actually matter – selling and taking care of your customers.

Other problems emerge as you scale – let’s say you’ve somehow figured things out, and have made DTC fulfillment work with these two traditional 3PLs. As you grow further, you start sending pallets to retailers all over the US, such as Target, Nordstrom, or Macy’s. Suddenly, your 3PL has no space for your containers and struggles to handle B2B fulfillment. Additionally, many of these traditional 3PLs may lack the EDI technology which is a prerequisite to work with many retailers and brands.

Peer-to-Peer – Accelerates Growth By Scaling Alongside You

Let’s imagine you’re the Midwest brand again. This time, you’re working with Cahoot’s peer-to-peer network. When you start out, you ship orders from one of our Midwest fulfillment centers, providing customers with free, fast shipping.

When your brand surges in popularity, things don’t fall apart – you simply add more nodes on the Cahoot network to fulfill orders from. You use our fulfillment centers in Southern California to ensure you deliver a high-quality experience to your customers on the West Coast.

You also work only with 1 vendor, offering you 1 contract. This ensures you can scale nationwide fulfillment, with none of the process management overhead that working with traditional 3PLs brings.

We also have experience and expertise in handling B2B fulfillment, in addition to DTC fulfillment. Whatever the spike in order volume you see, we’ll make sure that you actually celebrate your success. You won’t be spending your time thinking, “Can our fulfillment keep up with all this growth?”

Traditional 3PL – Great for Regional Shipping

Traditional 3PLs do a reasonably good job of servicing the specific parts of the country that they are located in. For example, a traditional 3PL on the West Coast might be great for orders in all states in that part of the country.

Because of the restrictions on the number of locations they have, these 3PLs find offering nationwide coverage at affordable rates extremely difficult.

While these models may work for brands with a strongly regional customer base, the problem is that nearly every seller dreams of scaling nationally and globally at some point – these 3PLs can often become a hindrance when the sellers do decide to start expanding.

Peer-to-Peer – Great For National Programs Like Amazon SFP

Previously, Amazon’s Seller Fulfilled Prime (SFP) program had a regional component – brands could fulfill orders just in their region of the country on their own while still featuring the Prime badge on their product listings on the Amazon marketplace. However, Amazon now expects fast shipping across the entire contiguous U.S. on the program – products across every size category must be delivered in 3-5 days, while approximately 70% of orders on standard-sized products must be delivered in 2 days or less.

Traditional 3PLs will find it nearly impossible to meet this requirement using ground shipping because of their location constraints. Using air shipping is not an option for sellers in most cases because that erodes any cost savings they were hoping to see over FBA.

Analytics and Reporting

Traditional 3PLs – Decisions Made on Instinct

Traditional 3PLs tend to make most decisions using a combination of intuition and guessing. Some of the most crucial pieces of the eCommerce order fulfillment workflow are – Which warehouse to dispatch an order from, and which box to pack the items in?

Most traditional 3PLs do not have the purpose-built technology needed to determine the warehouse each order should be sent from. At best, a rudimentary heuristic based on the customer’s ZIP code might be deployed. The problem is that you could be losing money on every shipment. Until you invest in the right technology, you’ll never actually know the full extent of your losses.

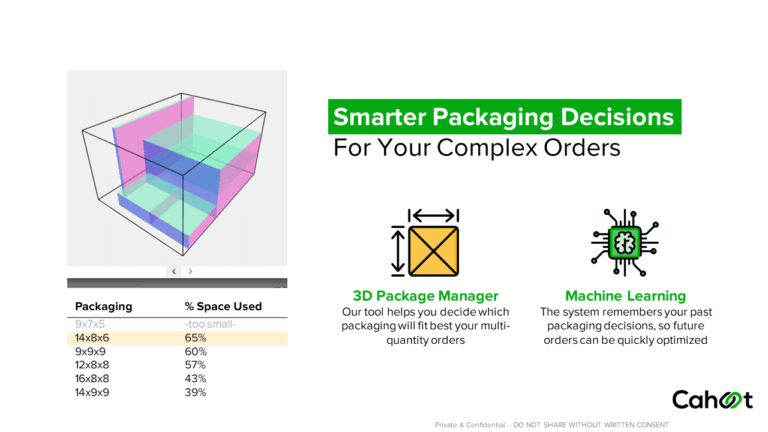

The second crucial factor is the choice of box to use. Traditional 3PLs have a limited number of boxes of the most popular sizes. They randomly throw products into any box that fits. In the best case, an ad-hoc heuristic might be defined to map each SKU to a box, by eyeballing the box and product sizes. This creates problems on multiple dimensions. The first is that the overall cost of packaging materials continued to increase at a pace faster than inflation, while the cost of paper and cardboard increased by as much as 9% in 2024. This means that if you’re selecting larger sized boxes on each order, your costs surge. More crucially, the shipping carriers set their prices in tiers, based on the dimensional weight of items. This means that the wrong choice of box for a lightweight item can tip it over into a higher pricing tier than is actually needed. Sellers can bleed money on both avenues – cost of supplies, and the fees they pay to the shipping carriers. Today, there is also a growing consumer demand for environmentally responsible, sustainable packaging. When items reach environmentally conscious consumers in oversized boxes, it can negatively impact the experience they have with your brand.

Lastly, most traditional 3PLs do not offer enough variety of warehouse locations to actually place your inventory close to where most of your customers live – even in cases where they have multiple warehouse locations, they could still place your products in the wrong fulfillment center!

The only way to eliminate ambiguity and make the optimal selection each time is to ensure decisions are guided by past data and real-time technology automation – unfortunately, most 3PLs do not offer that.

Peer-to-Peer – Decisions Informed by Data

With Cahoot’s Peer-to-peer network, we let data and technology make the most critical decisions.

For order routing, our next-generation software intelligently compares multiple warehouse locations, carriers and shipping services before picking the most optimal location and service that can meet the delivery promise committed to the customer.

We use advanced 3D bin technology to evaluate the fit of items in boxes, ensuring that each SKU goes into the best-sized box. Our software also comes with intelligent automation for Multi-Line, Multi-Quantity (MLMQ) orders, where our system learns from box and SKU dimensions, as well as past packaging choices to optimize box selection.

Lastly, while warehouses on our network are located near major population centers, it still means nothing if we don’t place your inventory in the location closest to where most of your customers live. We go deep and sweat the details to identify geographic trends in your historical orders, ensuring that we set you up to see maximum savings.

Flexibility and Agility

Traditional 3PL – High Switching Costs, Hidden Fees, Painful Migration

Traditional 3PLs often do not operate with flexible, merchant-centric models where you can build from what you have. Like we mentioned earlier, each of them comes with limited geographic coverage of the country, and offers their own pricing contract and SLA.

Let’s say you’re working with a traditional 3PL that gives you coverage on the East Coast. While their services are good, you’re trying to find out if there’s a way for you to expand to the West Coast. Traditional 3PLs do well when they have as much of your inventory tied to their warehouses as possible. You may be hit by high fees on both fronts – the removal fees from the East Coast 3PL, and the inbound fees with the West Coast provider.

Worst of all, once you do manage to migrate your inventory over, you’ll still have to deal with the process management overhead that comes from working with two fulfillment partners.

While this does not sound like an easy process, we’ve put together a step-by-step guide on how to migrate from one fulfillment partner to another.

Peer-to-Peer – Seamless, Painless Migration

A Peer-to-Peer Network is the most merchant-centric, merchant-inclusive platform for Order Fulfillment. Cahoot’s Peer-to-Peer network is not a ‘winner takes all’ arrangement. We’re not only an option for merchants looking for ultrafast eCommerce order fulfillment, but also an option for 3PLs looking to serve their customers better.

When our customers are happy with using their existing 3PL to serve a particular part of the country, say the West Coast, we can flexibly scale nationwide coverage on top of their current setup. They can bring their 3PL to our network, where we provide them with an economical way to cover the East Coast.

In fact, one of the biggest features of the peer-to-peer model is that it can be a way through which traditional 3PLs can overcome their geographical constraints while helping merchants achieve free, fast nationwide shipping.

Integration and Consistency

Traditional 3PL – Extremely Fragmented, Increased Overhead

Many traditional 3PLs were designed for the older, pre-Amazon Prime era of eCommerce when merchants fulfilled orders from just one or two channels. In today’s world of online marketplaces, traditional 3PLs may not support all of the different marketplaces. You may have to work with one 3PL for your Walmart orders, while handling Shopify fulfillment through another. The depth of integration also matters – for example, does the technology these 3PLs use transmit inventory count information back to the sales channel so that you avoid receiving orders on out-of-stock items? Can they transmit tracking information back to the channel? And does your order fulfillment help you meet the unique expectations customers have on each marketplace?

As you work with multiple 3PLs, your ability to offer consistent order fulfillment may be severely compromised. With these providers, handling the basics of order fulfillment becomes challenging. When it comes to exception management on specific orders, the problem worsens.

Let’s imagine you’re working with warehouses from two 3PLs, each with their own SLA – the first has a cutoff time of 1PM, the second 12PM. Suppose an order comes in at 12 30 PM – but there’s been an unexpected issue with the first warehouse. You’re unable to reroute the order to the second warehouse because it’s already past the cutoff time there. The problem stems from the fact that each warehouse has its own SLA and none of them are integrated to each other.

If you’re seeking to expand sales channels or achieve nationwide coverage, the number of such fragmented, siloed warehouse nodes increases exponentially – drowning you and your team in process management. You may need to hire dedicated people to babysit and oversee this operation, which negatively hits your costs.

Peer-to-Peer – Unified, Simple and Consistent Across Every Channel

With a Peer-to-peer fulfillment network, you get custom-built, out-of-the-box integrations for all major marketplaces. We pull all the critical information about orders and their delivery due dates into our system, while pushing back updated inventory and carrier tracking information to the respective channel. This extends to our fulfillment operations – we ensure that you stay compliant with the unique requirements that each marketplace has, such as usage of a particular shipping carrier / service, or branded packing slips.

With Cahoot, you spread your inventory across multiple warehouses, but work with just one partner. This ensures that you can offer a consistent experience on every order. This solid foundation makes exception management much easier to handle. When orders may not make it in time because of issues at one node, we can intelligently reroute it from another location with minimal overhead. We also offer consistent SLAs and every node on the network is tightly connected.

With a Peer-to-peer fulfillment network, the number of warehouses and sales channels increases, but there’s always only minimal process management needed. You and your team will get back more time to focus on growing the business.

Environmental Sustainability

Traditional 3PLs – Excess Packaging Waste and Greenhouse Gas Emissions

Customers today expect brands to be sustainable and environmentally responsible in their operations. A traditional 3PL exacerbates problems for brands across 2 different dimensions, packaging, and emissions.

Traditional 3PLs tend to have a random, haphazard approach to packaging – they have a few boxes of the most popular sizes, and the warehouse staff simply place the item into whichever one might be available on hand.

When the customer receives the order, they might be annoyed that their item was delivered in an overly large box, generating more waste for the environment. For environmentally-conscious shoppers, such experiences can ruin their relationship with the brand, completely turning them off from future purchases.

A bigger problem can arise because of the limited number of warehouse locations. Due to this, they’re forced to use air shipments or keep packages in transit for longer on the road. All this increases emissions released, worsening your brand’s carbon footprint and weakening your sustainability credentials.

Peer-to-Peer – Eliminate Packaging Waste and Slash Emissions

While our network of strategically located warehouses, you’ll nearly never use air shipping (unless customers specifically ask for it). You’ll be able to offer fast and economical ground shipping – which is great for your customers and the environment. But we go a step further and help you cut down packaging waste also.

As we mentioned before, our software’s 3D Bin Technology and its Multi-Line, Multi-Quantity Automation features help ensure you always use only the necessary amount of packaging material.

Lastly, environmental sustainability is the core cause that a peer-to-peer network is fighting for – in a world where everyone is using up more resources to build logistics infrastructure for their own private network, we’re aiming to use the Power of Many to build a more sustainable fulfillment network, without compromising on today’s sky-high customer expectations.

Reliability

Traditional 3PL – Fail to Live up to Their Promises

Most people tend to choose a traditional 3PL because they think a company dedicated to logistics and shipping can do a better job than a fellow merchant fulfilling your orders for you.

However, as we’ve discussed in the sections above, we think traditional 3PLs are still operating to serve the old paradigm of eCommerce. While you may feel that you are ‘in safe hands’ initially, the reality may be very different and disappointing.

Most traditional 3PLs may promise a lot, but struggle to deliver even the basics. Where does this disconnect come from? Most sellers are extremely busy and cannot afford to spend endless hours vetting their 3PL’s performance and services. Decisions may be taken with limited information and time – unfortunately, this leads to a lot of unpleasant surprises after the inventory has been received and orders start flowing in.

It’s worth asking – how can merchants rigorously vet their 3PLs to make sure their claims are actually true? With Cahoot, you won’t have to worry about that – because we’ve already taken care of that.

Peer-to-Peer – Only The Best Warehouses Pass Cahoot’s 44 Point Checklist

Some people think that working with a traditional 3PL (with their own warehouse space) is better than operating in a peer-to-peer network. Most people who feel this way share one concern, “How Can I Trust Another Merchant to Deliver My Orders?” A similar concern was shared by many people when Uber first rose to popularity, defeating the cabbies in London and New York’s famous Yellow Taxi. In London, people must spend 3 years training to be accepted as a cab driver. With Uber, nearly anyone could start driving taxis instantly. A similar sort of nervousness was prevalent among people, who asked, “How can we trust getting in a car with a stranger?” Interestingly, the data challenges the popular perception – according to research conducted at NYU, humans trust authentic sharing economy workers more than their neighbors and colleagues (and nearly as much as their families). The keyword in that sentence is authentic. Authenticity is built by high levels of trust and transparency – such as Uber drivers providing their details and a profile picture on the platform.

Similarly, we recognize that building authenticity is crucial. Order fulfillment is a crucial aspect of business operations, and you don’t want to be handing that task over to someone you can’t trust. We foster trust with our sellers by rigorously vetting fulfillment partners. Cahoot has a 44-point checklist that warehouses must pass if they are to become part of our eCommerce order fulfillment network. This ensures that only the best warehouses, with excellent packing practices and order fulfillment standards, make the cut. Cahoot also has zero tolerance for defects and regularly reviews the performance of its fulfillment partners. We think that a warehouse in the Cahoot network has been through more rigorous vetting than the review that the average seller does on a traditional 3PL. This means that there’s a good chance that a Cahoot warehouse is better than the one at your traditional 3PL. With our vetting and audits, you can rest assured that it’s a safe and trustworthy one, too.

Privacy and Security

Traditional 3PLs – Lax Data Security Measures

With traditional 3PLs, your customer information moves across multiple systems without proper safeguards. They might request for all your order and customer information to be transmitted to whatever technology they are using. If that is different from their shipping software, then your proprietary data enters another system outside your purview.

While you may have signed contracts with the 3PL, your data still rests on multiple systems that they operate, with minimum visibility. Worse, you are entirely reliant on their information security practices, which may be minimal or even non-existent.

In the era of Europe’s General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA), no company can afford a data breach. Under a regulatory framework like GDPR, customers have the right to request for deletion of their data. If sensitive details like their name, phone number and address are already on systems that your 3PL controls, it increases exposure and risk to your business.

Peer-to-peer – Robust Data Privacy and Governance Measures

While having confidence in the order fulfillment standards of our warehouses is important, another concern sellers might have is, “How can we trust that other merchants will not see or use our customer data?” While Uber built high levels of trust in people, it still could not change the fact that people were indeed getting into a car with a stranger. To safeguard its customers and set their fears at ease, Uber has put in place various safety measures on its app. Some of these include GPS tracking, the ability to transmit location information to emergency services, logs of historical trips as well as the very famous rating system – where both riders and drivers review each other after each ride (a social incentive to behave respectfully).

With Cahoot’s peer-to-peer fulfillment network, you can sit back and relax knowing that every order will be fulfilled on time. However, we do know that another merchant is responsible for fulfilling your order, and take data privacy extremely seriously. We provide a single platform where you get total control and visibility into your data. When our fulfillment partner prints a label to ship your order, they see the customer’s first name, but only the initial of their surname. Only the absolute essential information needed for order fulfillment is shared with the fulfillment partner, while all other product / brand / customer information remains with the seller.

Community

Traditional 3PL – You Work With a Vendor

Working with a traditional 3PL is often nothing more than a transaction – you pay them a lot of money, and they perform the task of order fulfillment for you. While getting your orders out to customers is vital, there’s often little differentiated value addition that you get from the engagement.

Peer-to-Peer – Work With a Partner Reduce Costs and Generate Revenue

With Cahoot’s peer-to-peer network, you can have ultrafast eCommerce order fulfillment by partnering with us. But it doesn’t have to end there. If you have excess capacity in your own warehouse, you can actually double up as a Fulfillment Partner on the network to monetize that and bring in additional revenue. Order Fulfillment is a growth driver, not a cost center – with us, those words definitely ring true. This is similar to Uber drivers in their home city becoming riders when they’re traveling!

Summary

While traditional 3PL companies are useful for the things they do well, they have limitations that can put pressure on sellers trying to succeed in the rapidly changing environment of modern ecommerce. For sellers trying to achieve Prime delivery standards without using FBA, or those that simply require nationwide reach for their fast delivery options, a traditional 3PL on its own is not sufficient.

Cahoot’s innovative fulfillment network combines the benefits of a traditional 3PL, but adapted to the needs of a modern online merchant. Ambitious sellers can no longer afford to limit their fast delivery options to certain regions, and they must submit numerous fees and conditions to get the reach.

Whatever your needs, Cahoot can deliver differentiated value to your business. Reach out to us today to get started!

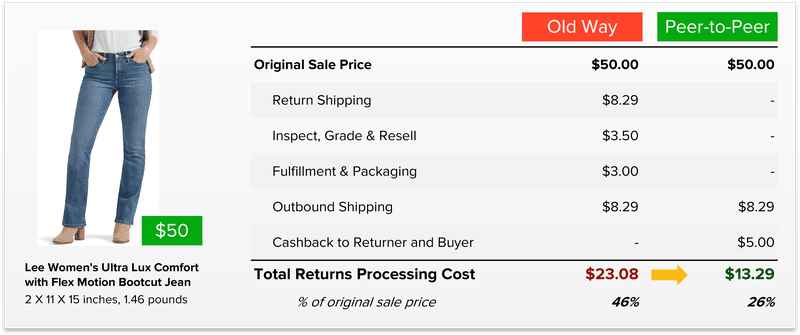

Up to 64% Lower Returns Processing Cost

33 minutes

33 minutes