3PL Warehouse Food Grade: How To Choose | Cahoot Fulfillment

Last updated on February 12, 2025

As more grocery sellers move to add online channels, they’re quickly discovering that the third party logistics industry hasn’t yet built up the specialized muscle needed to store and ship their products with the care they need. The growth of grocery online has caught logistics professionals off guard. After all, very few people bought food online as recently as 2019.

Just two years before the COVID pandemic, eCommerce made up only 2.7% of US grocery sales. Now, market forecasters expect it to make up a full 20% of the grocery market in 2026, an astounding growth rate.

Explosive growth can come with deep challenges, and many grocers that have added online channels have seen the promise of ecommerce turn sour due to high damage rates and inefficient shipping from their fulfillment partners. Unfortunately, many 3PL warehouses simply don’t know what it takes to offer top-notch services and manage food supply logistics effectively.

In this article, we’ll provide you with an inside look into what you need to look for in a 3PL that will support your profitable growth as an online food seller with food-grade warehouses.

What is Food Grade Warehousing?

Food grade warehousing refers to the specialized storage and handling of food products in facilities that meet stringent standards for cleanliness, sanitation, and safety. These warehouses are designed to protect the integrity and quality of food products, ensuring they remain safe for consumption throughout the storage period. Equipped with specialized equipment and staffed by trained personnel, food grade warehouses handle a variety of food products, including dry goods, frozen items, refrigerated products, and perishables.

In the food supply chain, food grade warehousing plays a critical role by preventing contamination, spoilage, and damage to food products. This ensures that the food reaching consumers is both safe and high-quality. By adhering to rigorous standards, food grade warehouses help maintain the trust and confidence of food manufacturers and consumers.

Importance of Food Safety in Warehousing

Food safety is paramount in food grade warehousing. Given the susceptibility of food products to contamination, spoilage, and damage, stringent food safety protocols are essential. These protocols include rigorous sanitation practices, effective pest control measures, and precise temperature control to inhibit the growth of harmful bacteria, mold, and other microorganisms.

Food grade warehouses must comply with regulations and standards set by authoritative bodies such as the Global Food Safety Initiative (GFSI) as well as legislation like the Food Safety Modernization Act (FSMA). These regulations ensure that food products are handled and stored in a manner that protects public health. By prioritizing food safety, food grade warehouses not only safeguard consumers but also uphold the reputation and reliability of the food supply chain.

What You Need From Your Food 3PL

While there are many similarities between fulfilling online orders for the food industry and general consumer packaged goods, food products have special needs that many third party logistics warehouses (3PLs) aren’t equipped to handle. Proper food handling practices are crucial to prevent contamination and ensure safety during storage and processing, with certifications like SQF and AIB validating adherence to these standards.

In this section, we’ll break down the added requirements that 3PLs need to excel in to provide excellent food grade order fulfillment.

FDA Approved Food Grade Warehouses

In 2011, the Food Safety Modernization Act (FSMA) raised the standards for manufacturing, processing, and storing food. An FDA-certified warehouse is a storage facility, food manufacturing plant, or order fulfillment center that is officially registered with the FDA to safely store food in accordance with the FSMA and food industry regulations.

The certification process ensures that the warehouse has a host of plans and procedures designed for the safe storage and handling of food products. Some elements include sanitation and cleaning procedures, glass and clear plastic policies, and pest control.

Relying on an FDA-approved warehouse as your food 3PL gives you the peace of mind that comes from knowing that your food products are stored safely, minimizing the chance of spoilage or contamination that could hurt customers and your ecommerce business.

In addition to FDA certifications, food-grade warehouses can acquire a number of other certifications from government and industry groups that indicate they are following up-to-date best practices for food handling and storage:

- Global Food Safety Initiative (GFSI) Recognized Certifications

- BRCGS (Brand Reputation Compliance Global Standards) Storage & Distribution – Ensures proper storage and transportation of food and packaging materials.

- SQF (Safe Quality Food) Storage & Distribution – A globally recognized standard that verifies food safety and quality management.

- IFS Logistics – Covers food and non-food storage and transportation requirements.

- FSSC 22000 (Food Safety System Certification) – Based on ISO 22000 and recognized by GFSI.

- ISO Certifications

- ISO 22000 – International standard for food safety management systems.

- ISO 9001 – Quality management system certification that ensures consistent service quality.

- Organic and Specialty Certifications

- USDA Organic Certification – For warehouses handling organic products, ensuring compliance with National Organic Program (NOP) standards.

- Non-GMO Project Verified – For warehouses storing non-GMO products.

- Gluten-Free Certification – Ensures compliance with gluten-free handling requirements.

- American Institute of Baking (AIB) – evaluates the safety, cleanliness, and compliance of food processing and storage facilities.

- Hazard Analysis & Critical Control Points (HACCP) Certification

- A preventive approach to food safety, identifying and managing potential hazards in food storage and handling.

Thanks to Cahoot’s unique peer-to-peer ecommerce model, we have warehouses that don’t just occasionally work with food products but instead have specialized in food order fulfillment for decades.

Climate Controls

One of the most important considerations when choosing an ecommerce fulfillment company is the type of climate conditions that your products will require. More than most other products, many foods have strict temperature limitations that must be followed, or products will be damaged. Many sellers assume that if they don’t need refrigeration, then any 3PL warehouse will do, but they learn the hard way that isn’t true.

Unfortunately, many 3PLs maintain warehouses at warmer temperatures in order to save money on air conditioning, which makes them too warm for many food items. Especially in summer months – and in the southern US – many warehouse temperatures rise into the 80s or even 90s Fahrenheit, which can irreversibly damage many food items and lead to a big write-down.

And product loss in the warehouse isn’t where the problem ends. Your outsourced warehouse team may not realize that products are damaged before they ship them out. Suppose you sell chocolates, and you have a product line that ships in opaque boxes. The warehouse team wouldn’t be able to see the damage, and if the warehouse temperature rose to melt the chocolate, shipments would continue without pause. That leads to a mass of customers all receiving damaged products at once, and when they take to social media to complain, it will create a lasting negative impression of your brand.

Therefore, it’s critical that the 3PL warehouse that you choose is equipped to handle, store, and ship your food items in optimal climate conditions so that your customers are able to receive the very best version of your product.

A good rule of thumb is to ask your 3PL warehouse whether they guarantee their warehouses at or close to room temperature. Since the most commonly shipped food items are designed to be stored in cool, dry conditions in a cupboard, they’re usually safe at 72 degrees. That being said, know your product! Refrigerated items will obviously require lower temperature ranges, and some other products don’t need refrigeration but do need more careful heat regulation than simply sitting at room temperature.

Careful Packaging For Safe And Efficient Shipping

One metric defines online seller profitability more than any other: customer lifetime value. With digital advertising becoming increasingly expensive, most sellers lose money on new customers. They’re only able to earn a positive bottom line through long-time repeat customers.

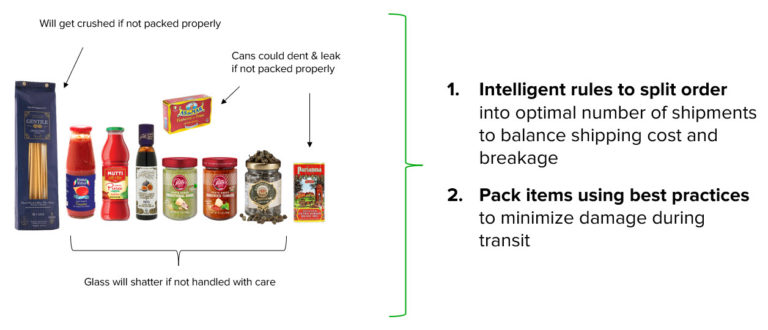

Proper food grade storage is essential before shipping to ensure food safety and compliance with regulations. Unfortunately for online food merchants, it’s more difficult to safely ship fragile foods and glass than it is to ship other goods. Without a food 3PL that knows how to treat such delicate items, your margins will quickly be overwhelmed by unhappy customers demanding refunds for damaged goods.

In addition to limiting damage, a 3PL warehouse that knows food logistics inside and out also knows that orders come in many more shapes and sizes than they often do for other merchants. Grocery orders tend to consist of many different items and many different quantities. This introduces significant packaging uncertainty for untrained order fulfillment personnel, and it can lead to inefficiently packed boxes that inflate shipping costs.

Cahoot uses a combination of intelligent packing software and responsive customer service to get the packaging right for the toughest goods to ship. We optimize for two things: we keep the package as small as possible to minimize shipping cost while also getting damage rates as close to 0% as possible.

Our warehouses that specialize in food have a direct line to discuss tricky packing challenges with our control team, and this leads to a process of continuous improvement. Our software is constantly learning new ways to reduce damage rates and costs. In this way, you save money on shipping while also ensuring that your customers are delighted when they open up their products every time.

Responsive Customer Service

Though responsive customer service is important for all online sellers, it’s especially important for a food 3PL, given the additional attention that is needed. You need to be able to get in touch with your customer service team quickly to feel confident that they know how to excel with your products and troubleshoot solutions for tricky challenges.

You need a 3PL company that offers you a real person to work with your account and multiple ways to get in touch with them. Cahoot clients love our easy-to-reach and proactive customer service team. Our team is based in the USA, and they take the time to get to know your ecommerce business, so you don’t have to start at square one with a new person every time you submit a ticket. The close relationship we forge with our sellers is foundational to our ability to go above and beyond as a food 3PL.

Evaluating a Food Grade Warehouse

When evaluating a food grade warehouse, it’s crucial to assess its ability to meet high standards for cleanliness, sanitation, and safety. Here are key factors to consider:

- Certifications: Look for certifications such as SQF, AIB, and Organic. These certifications indicate that the warehouse adheres to specific standards for food safety and quality.

- Sanitation and Pest Control: Ensure the warehouse has a robust sanitation and pest control program to prevent contamination and infestation. This includes regular cleaning schedules and effective pest management strategies.

- Temperature Control: Verify that the warehouse has adequate temperature control measures to prevent spoilage and damage to food products. This is especially important for perishable and temperature-sensitive items.

- Inventory Management: Assess the warehouse’s inventory management system to ensure it can effectively track and manage food products. Efficient inventory management helps in maintaining product quality and reducing waste.

- Staff Training: Ensure that warehouse staff are well-trained in food safety and handling procedures. Proper training minimizes the risk of contamination and damage to food products.

- Regulatory Compliance: Verify that the warehouse complies with relevant regulations and standards, such as the Food Safety Modernization Act (FSMA). Compliance ensures that the warehouse operates within legal and safety guidelines.

By thoroughly evaluating these factors, you can ensure that a food grade warehouse meets the necessary standards for safely and efficiently storing and handling food products. This not only protects consumer health but also enhances the reliability and efficiency of the entire supply chain.

Cahoot: Experienced Food Grade Warehouses

Cahoot is different from other 3PLs. Our innovative peer-to-peer model sets us apart by enabling us to offer low-cost, fast order fulfillment by design for a huge variety of specialized industries.

So, how do peer-to-peer ecommerce services work better than old order fulfillment networks?

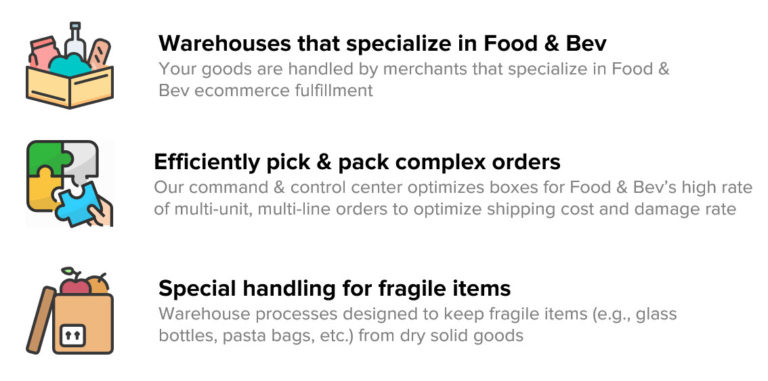

We recruit top-tier ecommerce merchants with their own warehouses to join our network as fulfillment partners, and then our intelligent shipping software and control team keeps the whole system connected and running efficiently. Since we’re unlocking excess order fulfillment capacity that was lying idle, we’re able to offer lower costs. And crucially for online grocers, we’re able to recruit merchant-operated warehouses that already specialize in fulfilling their own food – and thus are already up to speed as food grade warehouses.

Unlike other 3PL warehouses that are building cookie-cutter warehouses designed to store easy-to-fulfill goods, we have specialists in temperature-controlled fulfillment, hazmat, and more. Our flexibility is part of what distinguishes us and makes us the best choice for sellers seeking a reliable food-quality 3PL partner.

Our technology further improves our ability to power food-grade logistics by constantly optimizing how we pack orders. The shipping software partners with human judgment to learn the best packing combinations for tricky food orders, so we’re able to minimize damage rates and use small packages to limit shipping costs. And, of course, since our merchant-operated warehouses know how important special handling is for food products, they take extra pride in ensuring that your products are safely stored and moved.

If you’d like to find out how Cahoot can help your ecommerce business, please get in touch with us. We’ll design a custom order fulfillment service for you that will meet your exact food-grade needs.

Frequently Asked Questions

What is 3PL cold storage?

3PL cold storage refers to temperature-controlled warehousing and distribution services for perishable goods offered by many 3PLs. These facilities specialize in storing and handling products that require refrigeration or freezing, such as dairy, meat, seafood, frozen meals, pharmaceuticals, and certain chemicals.

What regulations must a food-grade 3PL provider follow?

Food-grade third-party logistics (3PL) providers must comply with several regulations to ensure food products are stored and handled safely. Key requirements include:

- FDA Registration: All food-grade warehouses must be registered with the FDA and undergo regular inspections.

- FSMA Compliance: Facilities must implement a comprehensive Food Safety Plan managed by a Preventative Controls Qualified Individual (PCQI).

- GMPs & HACCP Plans: Good Manufacturing Practices (GMPs) and Hazard Analysis Critical Control Points (HACCP) ensure food safety and risk mitigation.

- Third-Party Audits: Many food-grade warehouses are subject to independent audits by organizations such as ASI Food Safety or the Safe Quality Food Institute (SQFI).

- Pest Control & Sanitation: Strict pest control, sanitation, and hygiene protocols must be followed to prevent contamination.

What factors should businesses consider when choosing a food-grade 3PL provider?

When selecting a food-grade 3PL provider, businesses should consider several factors to ensure compliance and efficiency, including experience & certifications, temperature integrity, lot traceability, prevention of cross-contamination, and GMP audit readiness.

What can disqualify a warehouse from being considered food-grade?

A warehouse may lose its food-grade status if it fails to maintain sanitation, temperature control, and compliance with regulatory standards. Common disqualifications include:

- Structural Issues

- Poor Sanitation Practices

- Improper Storage

- Lack of Temperature Control

- Regulatory Non-Compliance

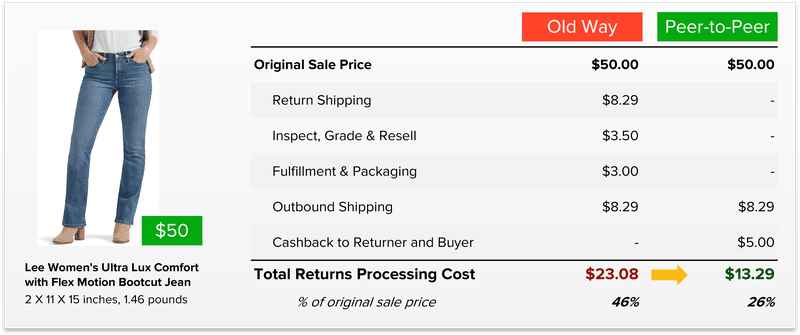

Up to 64% Lower Returns Processing Cost

13 minutes

13 minutes