Ecommerce Shipping Challenges: The World Has Changed and Traditional Shipping Software is Not Enough

Last updated on March 19, 2025

In this article

16 minutes

16 minutes

- The ‘Old World’ of Ecommerce: Lower Complexity

- The ‘Old World’ of Ecommerce: Lower Costs

- Inefficiency in Operations Did Not Impact Margins

- The ‘New World’ of Ecommerce: High Operational Complexity

- Rising Costs

- Efficient Operations Essential for Margins and Profits

- Why Sellers Need to Switch to Next-Gen Ecommerce Shipping Software

- Summary

- Frequently Asked Questions

At Cahoot, we believe today’s ecommerce industry needs next‑generation shipping software. Selecting the best shipping software is crucial for enhancing efficiency and customer satisfaction. But before we talk about this amazing technology, it’s first worth asking – why is now the time? After all, legacy shipping software has been around for years. Thousands of Sellers are already using these tools – why make the switch?

We believe the present moment is perfect because ecommerce is dramatically different from how it looked just twenty years ago. The event that changed everything was the introduction of Amazon Prime in 2005. Just like the first iPhone revolutionized society’s experience with personal technology, Prime’s introduction transformed everything in the ecommerce industry. Sellers had to throw out old strategies and create entirely new ones to run their businesses.

The differences are stark, but we’ve summarized them in this table:

|

Parameter

|

Old World (1990’s, early 2000’s)

|

New World (ChatGPT – Present)

|

|---|---|---|

|

Sales Channels |

Just one |

Many, ever‑increasing |

|

Competitive Pressure |

Minimal |

Intense |

|

Customer Expectations |

Low |

Sky high |

|

# Warehouses |

Just one |

Four or more |

|

Carrier Mix |

Sign one contract |

Rate‑shop across multiple carriers |

|

Order Profile |

Small and simple |

Large and complex |

|

Carrier GRI |

Stable for decades |

Increasing |

|

Warehouse Staffing |

Easier and economical |

Wages keep going up |

|

Warehouse Leasing |

Less competition for space |

Heavy demand for scarce space |

Let’s begin by going back to the 1990s and journey through the early 2000s to see what the ‘old world’ of ecommerce looked like, for Sellers and customers. By understanding these changes, we can see how modern shipping solutions can turn challenges into a competitive advantage.

The ‘Old World’ of Ecommerce: Lower Complexity

In the olden days of ecommerce, life was simpler. Fewer channels to manage, fewer customer expectations, and less technological complexity meant uncomplicated logistics and order fulfillment processes that seem almost quaint by today’s standards.

Just One Channel to Manage

In the old world, Amazon was not the ‘everything store’ yet. It was largely a first‑party Seller of a few products like books, CDs, and DVDs. They did not face much competition – Walmart and Target restricted themselves to physical stores while shopping cart platforms like Shopify and BigCommerce did not exist. All this meant that Sellers did not have multiple sales channels to sell and take care of customers on. There was usually just one channel – their own website. With just one channel to support, it was also possible to operate with smaller‑sized teams.

Minimal Competitive Pressure

In the 1990s, online marketplaces did not exist. Amazon launched its third‑party marketplace only in 2000. In this environment, customers did not have a lot of choices. Sellers had to ensure they drew customers to their website through good marketing. Once they found you, it was not easy to comparison‑shop across different listings, brands, or platforms. There was little pressure on Sellers – it was unlikely a competitor would undercut you on price or beat you on shipping speed.

Low Customer Expectations

Perhaps most importantly, customers had no expectation of free and fast shipping. Before Prime’s introduction in 2005, customers had never tasted that experience. They were willing to wait 7–10 days for orders and covered the cost of shipping. Even if they did not like this experience, there was no social media platform at the time where they could share their frustration.

Single Warehouse, Single Carrier

The combination of lower customer expectations and sales through a single channel meant that Sellers could get by with operating from a single warehouse location, or two if they really needed the space. Customers living far away were okay with waiting as long as 1–2 weeks for their orders. Because customers were willing to cover shipping costs, Sellers saw no reason to compare and find the lowest rate among multiple carriers. It was easier to just sign a contract with one carrier. Why bother with cost optimization when the customer was paying?

Small and Simple Orders

In the old world, lower basket sizes (units per transaction) were common because customers were yet to trust making payments over the internet. The least risky way to test ecommerce was to just buy one item. As confidence grew, so did basket sizes. Multi‑Line, Multi‑Quantity (MLMQ) orders were less frequent, reducing warehouse packing complexity.

In summary, Sellers faced little complexity in running their businesses in the old world. They sold on a single channel, faced minimal competitive threats, and could easily satisfy customers. All of this translated into simpler operations across the shipping lifecycle.

The ‘Old World’ of Ecommerce: Lower Costs

We’ve taken a look at how operationally simpler it was to run an ecommerce business in the old world. But this was not the biggest advantage Sellers had – we’ll now explain how costs were lower back then.

Shipping Costs Were Cheaper

Carrier General Rate Increases held steady at 4.4%–4.9% through the 1990s and into the 2010s, which provided predictability and control over delivery costs.

Labor was Cheaper

In the old world, ecommerce did not require massive warehouse labor networks. Sellers could staff warehouses at wages that protected margins, as fewer large players competed for workers.

Warehouse Space was Cheaper

Warehouse demand was lower, so Sellers could find and lease space more easily and at lower rates. Fewer ecommerce operations competed for limited industrial real estate.

Across the fulfillment workflow, Sellers had cost certainty. Carrier rates, labor wages, and warehouse leases were steady, protecting margins without constant optimization.

Inefficiency in Operations Did Not Impact Margins

In a world without marketplaces, customers paid shipping fees and lacked social media to complain. There was no pressure to optimize operations or cut costs – margins remained protected without innovation.

The ‘New World’ of Ecommerce: High Operational Complexity

Prime’s launch in 2005 changed ecommerce permanently. Today’s Sellers operate in a vastly more complex environment.

Many Channels to Manage

Amazon’s third‑party marketplace, Walmart, Target, Shopify, BigCommerce, and others mean Sellers must sell and support customers across multiple platforms. This requires larger teams and integrated shipping solutions.

Intense Competitive Pressure

Online marketplaces give customers infinite choice. Sellers face constant threats of price undercuts, faster shipping, and knock‑offs. High shipping costs further squeeze margins.

Sky High Customer Expectations

Customers now expect 1‑day and 2-day free shipping. Cart abandonment soars without transparent free, fast options and social media amplifies complaints.

Multiple Warehouses, Multiple Carriers

To meet fast, free delivery, Sellers must distribute inventory across strategically located warehouses and rate‑shop among many carriers. Multi‑carrier shipping software automates this complexity.

Large and Complex Orders

Higher free‑ship thresholds and multi‑item carts drive more Multi‑Line, Multi‑Quantity (MLMQ) orders, requiring more varied box sizes and longer packing times.

Sellers today juggle multiple channels, unrelenting competition, and sky‑high expectations — reinventing every step of shipping with distributed fulfillment and intelligent software.

Rising costs

Complexity isn’t the only challenge — costs have also soared in the new world.

Shipping Cost is Expensive

Carrier GRIs jumped to 5.9% in 2022, 6.9% in 2023, and 5.9% in 2024 and 2025 — well above historical norms and inflation, leaving Sellers scrambling to adjust budgets and operations.

Labor is Expensive

Warehouse wages have risen as Amazon, Walmart, and Target compete for labor. In some regions, $20/hr has become the baseline, making staffing more costly for smaller Sellers.

Warehouse Space is Expensive

Warehouse rents soared during COVID‑19 and remain high as supply lags demand. Over 80% of U.S. warehouses were built before 2000, driving up lease rates.

Sellers now face rising carrier rates, labor wages, and lease costs, compounding the complexity of meeting modern customer demands.

Efficient Operations Essential for Margins and Profits

In marketplaces, creative cost‑saving and resource pooling are essential. Sellers must optimize operations to preserve margins, stay competitive, and win.

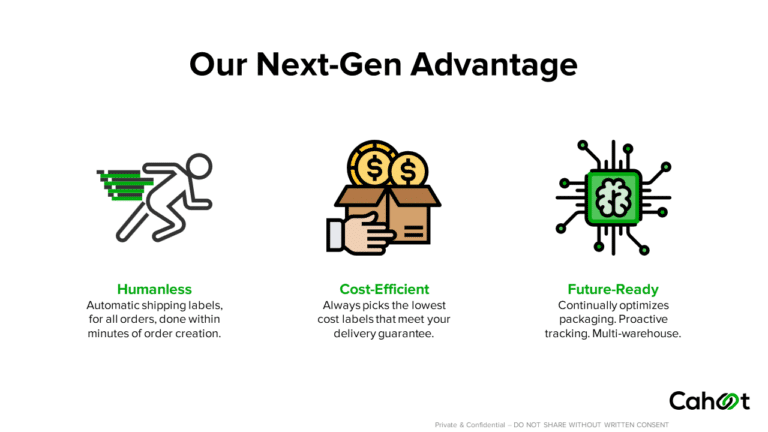

Why Sellers Need to Switch to Next‑Gen Ecommerce Shipping Software

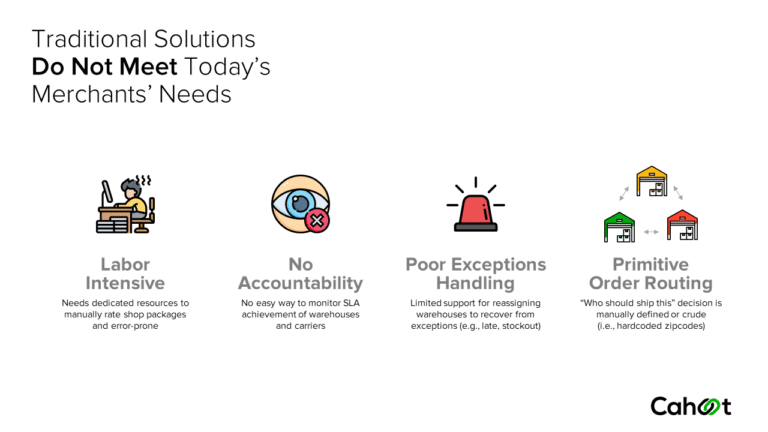

Legacy tools worked in the old world but add problems in the new one. They lack automation, cost savings, and multi‑channel flexibility, consuming time rather than simplifying workflows.

Choosing shipping software is crucial in developing an effective shipping and fulfillment strategy.

The next generation of ecommerce shipping software must solve three key problems:

- Simplify the operational complexities of the new world of ecommerce

- Drive operational efficiencies and productivity gains for your team

- Generate meaningful cost savings across each step of the shipping and order fulfillment workflow

In the coming sections, we’ll dive deeper into each of these aspects and explain how Cahoot’s next‑generation software is purpose‑built to address these challenges.

Summary

Ecommerce has come a long way. The simplicity of the past has given way to a fiercely competitive, complex environment where every decision matters. Traditional shipping software is now a relic, not a reliable tool.

To thrive today, businesses need software that simplifies complexity, enhances efficiency, and drives down costs in ways the old world never required.

At Cahoot, we’re actively shaping the future of ecommerce fulfillment. In today’s market, the right technology isn’t just helpful—it’s essential.

If you’d like to learn more, check out our Next Generation Shipping Software Guide, Part 2: “Shipping Software for Ecommerce Fulfillment: The Next Generation of Shipping Simplified”.

Frequently Asked Questions

How can I reduce shipping costs for my ecommerce business?

Reducing shipping costs requires a multi‑faceted approach:

- Negotiate rates with multiple carriers rather than relying on a single provider

- Consider using regional carriers for deliveries within specific areas

- Optimize packaging to reduce dimensional weight charges

- Implement zone skipping by shipping bulk orders to carrier hubs closer to final destinations

- Use shipping software that compares rates across carriers in real time

- Offer local pickup options for customers in your area

- Consider flat‑rate shipping for certain product categories

What are the most common causes of parcel delivery delays?

Several factors commonly contribute to delivery delays:

- Weather events and natural disasters

- Carrier capacity constraints during peak seasons

- Customs clearance issues for international shipments

- Address errors or incomplete delivery information

- Staffing shortages at carrier facilities

- Vehicle breakdowns or logistical issues

- High volume surges (e.g., Black Friday/Cyber Monday)

- Last‑mile delivery complications in rural or hard‑to‑access areas

How can I reduce the environmental impact of my ecommerce shipping?

To make your shipping more sustainable:

- Use right‑sized packaging to minimize waste and reduce dimensional weight

- Choose recycled or biodegradable packaging materials

- Offer carbon offset options at checkout

- Consolidate orders when possible to reduce the number of shipments

- Partner with carriers that have environmental initiatives or electric vehicle fleets

- Implement a packaging reuse program for returns

- Consider local fulfillment options to reduce transportation distances

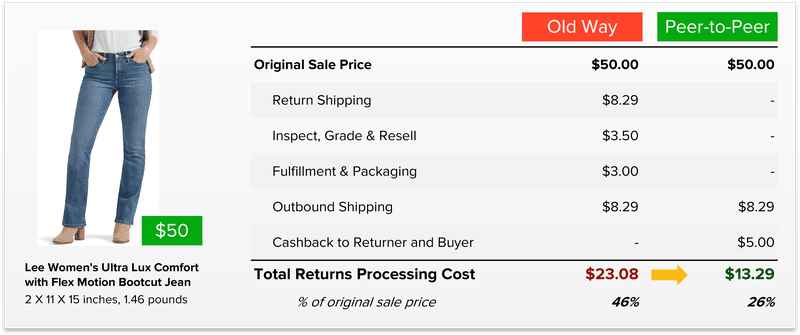

What should I do about rising return rates in ecommerce?

To address the challenge of increasing returns:

- Provide detailed product descriptions, measurements, and high‑quality images to set accurate expectations

- Implement a clear, easy‑to‑understand return policy

- Consider offering free returns as a competitive advantage

- Use analytics to identify products with high return rates and address underlying issues

- Implement a return merchandise authorization (RMA) system to streamline the process

- Consider restocking fees for certain categories to discourage unnecessary returns

- Offer virtual try‑on or AR features for appropriate products

How can I improve last‑mile delivery efficiency?

Improving last‑mile delivery, often the most expensive part of shipping, requires:

- Partnering with multiple carriers to diversify delivery options

- Implementing delivery management software to optimize routes

- Offering alternative delivery options like BOPIS (Buy Online, Pick Up In Store)

- Using lockers or pickup points in convenient locations

- Providing narrow delivery windows to improve customer experience

- Leveraging data analytics to predict delivery challenges in specific areas

- Considering micro‑fulfillment centers in urban areas for faster delivery

What are the best practices for international shipping in ecommerce?

For effective international shipping:

- Partner with carriers experienced in global logistics

- Understand customs documentation requirements for each country

- Use harmonized system (HS) codes correctly for all products

- Be transparent about duties and taxes that customers may need to pay

- Consider using a third‑party logistics provider specializing in international shipping

- Implement reliable package tracking for international orders

- Offer DDP (Delivered Duty Paid) options for a smoother customer experience

- Research import restrictions for products in your target markets

How can I manage shipping expectations during peak seasons?

To handle peak season shipping challenges:

- Plan ahead by increasing inventory and staffing well before peak periods

- Communicate realistic delivery timeframes to customers

- Consider implementing order cutoff dates for holiday deliveries

- Diversify carrier partnerships to spread volume across multiple providers

- Use shipping software that can automatically route orders to carriers with capacity

- Offer incentives for early shopping to spread out order volume

- Maintain transparent communication about potential delays

- Consider temporary local pickup options during extremely high‑volume periods

Up to 64% Lower Returns Processing Cost