Modern Order Fulfillment Strategies for Ecommerce Success

Last updated on March 5, 2025

In today’s fiercely competitive ecommerce landscape, ecommerce order fulfillment has evolved from a back-office operation to a critical strategic advantage. The journey from customer order to delivery can make or break businesses, influencing everything from customer loyalty to profit margins. Effective order fulfillment isn’t merely about moving products from point A to point B; it’s about creating a seamless experience that meets rising consumer expectations while maintaining operational efficiency.

In today’s competitive market, customers expect fast, reliable, and affordable shipping options. As a result, ecommerce businesses must prioritize order fulfillment to meet customer expectations and stay ahead of the competition. The foundation of successful ecommerce fulfillment begins with selecting the right fulfillment model for your business needs.

What is Order Fulfillment?

Order fulfillment processes involve receiving, processing, and shipping orders to customers. It encompasses several key activities, including managing inventory, picking and packing orders, and ensuring timely delivery to customers. A well-executed order fulfillment strategy ensures that customers receive their orders accurately and promptly, enhancing their overall shopping experience and encouraging repeat business.

Benefits of Optimizing Order Fulfillment

Optimizing order fulfillment can bring numerous benefits to ecommerce businesses. Some of the key benefits include:

- Improved Customer Satisfaction: Fast and reliable shipping options can significantly enhance customer satisfaction and loyalty. When customers receive their orders quickly and accurately, they are more likely to return for future purchases.

- Increased Efficiency: Streamlining the order fulfillment process can reduce costs and improve operational efficiency. By automating tasks and optimizing workflows, businesses can handle higher order volumes with fewer resources.

- Competitive Advantage: Offering fast and affordable shipping options can give ecommerce businesses a competitive edge in the market. Customers are more likely to choose retailers that provide superior delivery experiences.

- Increased Sales: Optimizing order fulfillment can lead to increased sales and revenue. Satisfied customers are more likely to make repeat purchases and recommend the business to others.

By focusing on these benefits, ecommerce businesses can create a more efficient and customer-centric order fulfillment process, driving long-term success.

The Order Fulfillment Process

The order fulfillment process involves a series of steps that ensure customer orders are received, processed, and delivered efficiently and effectively. In this section, we will break down the order fulfillment process into its key components and explore each step in detail.

Receiving and Inventory Management

Receiving and inventory management is the first step in the order fulfillment process, even before customers place orders. This involves receiving and storing inventory in a warehouse or fulfillment center. Effective inventory management includes tracking inventory levels, monitoring stock levels, and ensuring that products are stored in a way that prevents damage or loss.

Order Processing and Picking

Order processing and picking is the next step in the order fulfillment process. This involves processing customer orders, picking the relevant products from inventory, and preparing them for shipping. Efficient order processing and picking includes using picking strategies such as zone picking or batch picking to minimize travel time.

Shipping and Delivery

Shipping and delivery are the final steps in the order fulfillment process. This involves shipping orders to customers and ensuring that they are delivered on time. Efficient shipping and delivery meet customer expectations while still keeping shipping costs low.

Order Fulfillment Solutions

#1 – In-House Fulfillment

In-house fulfillment provides complete control over the entire process, allowing companies to oversee quality control, packaging, and shipping directly. This approach works particularly well for businesses with unique products requiring special packaging or handling, those with low order volumes, or companies selling high-value items where the unboxing experience serves as a brand differentiator.

However, in-house fulfillment requires significant investment in warehouse space, equipment, technology, and labor. As such, it usually operates out of a single location, which comes with additional shipping costs. It also creates challenges during seasonal peaks when order volumes can surge dramatically, potentially overwhelming internal resources and leading to delays.

#2 – 3PL Fulfillment

For many growing ecommerce businesses, third-party logistics (3PL) providers offer a compelling alternative to in-house fulfillment. These specialized companies manage warehousing, picking, packing, and shipping operations, allowing online retailers to focus on core competencies like product development and marketing. The 3PL approach offers several advantages: veteran fulfillment staff, scalability to handle growth and seasonal fluctuations, geographic distribution to reduce shipping times and costs, and access to advanced fulfillment technologies without capital investment.

Most importantly, 3PLs spread their fixed costs across multiple clients, creating economies of scale that can significantly reduce per-order fulfillment costs. However, businesses must carefully evaluate potential 3PL partners based on industry expertise, technology capabilities, geographic coverage, and reliability metrics before outsourcing this critical function.

#3 – Dropshipping

Dropshipping represents another fulfillment model that has gained popularity, particularly among new ecommerce entrepreneurs. In this approach, retailers don’t hold inventory at all; instead, when a customer places an order, the retailer purchases the item from a third-party supplier who ships directly to the customer. Dropshipping eliminates inventory investment, warehousing costs, and fulfillment operations, allowing for leaner operations and reduced financial risk. However, this model creates dependency on suppliers for product quality and shipping times, limiting control over the customer experience. Retailers using dropshipping must establish strong supplier relationships and clear performance expectations to maintain customer satisfaction.

Challenges and Complications

Inventory Management

Inventory management represents perhaps the most challenging aspect of ecommerce fulfillment. Too much inventory ties up capital and increases storage costs, while too little leads to stockouts and disappointed customers. Advanced inventory forecasting tools now use artificial intelligence and machine learning to analyze historical sales data, seasonal patterns, market trends, and even social media signals to predict demand with remarkable accuracy.

The rise of omnichannel retail has further complicated inventory management, requiring seamless integration between online and offline channels. Leading retailers now implement unified inventory systems that provide a single view of stock across ecommerce, physical stores, and distribution centers. This integration enables practices like ship-from-store, where retail locations fulfill online orders for nearby customers, and buy-online-pickup-in-store (BOPIS), which has grown tremendously since the pandemic. Effective omnichannel inventory management requires not just technological integration but also organizational alignment, breaking down silos between traditional retail and ecommerce operations.

Technology and Automation Necessities

Warehouse operations themselves have undergone dramatic transformation through automation and digitalization. Modern ecommerce fulfillment centers utilize warehouse management systems (WMS) to orchestrate the flow of products and information. These systems optimize pick paths to minimize worker travel time, direct batch picking operations for greater efficiency, and ensure accurate inventory counts. Mobile devices and wearable technology provide warehouse staff with real-time instructions and verification capabilities, reducing error rates.

Integrated technology stacks now connect ecommerce platforms, order management systems, warehouse management systems, transportation management systems, and customer service platforms. This integration enables real-time inventory visibility, automated order routing, dynamic carrier selection, and proactive exception management. For customers, it provides accurate delivery promises during shopping, consistent order status updates, and seamless communication across touchpoints. The most advanced systems leverage artificial intelligence to continuously optimize decisions, from inventory placement to shipping method selection, ensuring the optimal balance of service level and cost for each order.

How can in-house fulfillment technologically keep up without exorbitant cost?

Returns on the Rise

Returns management has evolved from an afterthought to a critical component of ecommerce fulfillment strategy. Online purchases are returned at three to four times the rate of in-store purchases, creating significant operational challenges and costs.

Progressive retailers now view returns as an opportunity to enhance customer loyalty rather than a necessary evil. Streamlined return policies, prepaid return labels, and convenient drop-off options reduce friction for customers. Behind the scenes, sellers must stay vigilant for patterns that may indicate fraud or quality issues requiring attention. Effective returns management doesn’t just mitigate costs; it creates opportunities to recover value and improve customer satisfaction.

The Future of Fulfillment

The future of ecommerce fulfillment points toward even greater personalization and sustainability. Customers increasingly expect delivery experiences tailored to their preferences—from packaging options to delivery windows to unboxing experiences. Simultaneously, environmental concerns are driving innovation in sustainable packaging, optimized delivery routes, and circular supply chains that minimize waste. Forward-thinking retailers are exploring micro-fulfillment centers within urban areas, using existing retail space for rapid order processing. Emerging technologies like predictive shipping, where orders are positioned in the distribution network before purchase based on forecasted demand, promise to further reduce delivery times while maintaining efficiency.

Conclusion

Ultimately, successful ecommerce fulfillment requires balancing sometimes conflicting priorities; customer experience, operational efficiency, and financial performance. Cahoot can help improve all aspects, while keeping costs down.

The most successful ecommerce businesses view fulfillment not as a cost center but as a strategic differentiator; one that delivers not just packages, but competitive advantage in an increasingly crowded marketplace.

Frequently Asked Questions

Should I handle fulfillment myself or use a 3PL?

As sales volume grows, 3PLs become more attractive to small businesses. A quick heuristic would be checking air vs ground shipping costs; having multiple warehouses helps cut down on expensive shipping.

What are some good KPIs to monitor?

Good KPIs for Order Fulfillment are Order Picking Accuracy (Correctly Picked Orders ÷ Total Orders Picked) and Order Cycle Time (Average Time from Order Receipt to Shipment)

How can I package orders efficiently?

Optimizing packaging is a great way to save on shipping costs. This is easy for single item orders, but multiple item orders and juggling many boxes swiftly becomes exponentially more difficult. Smart cartonization software automates this complexity.

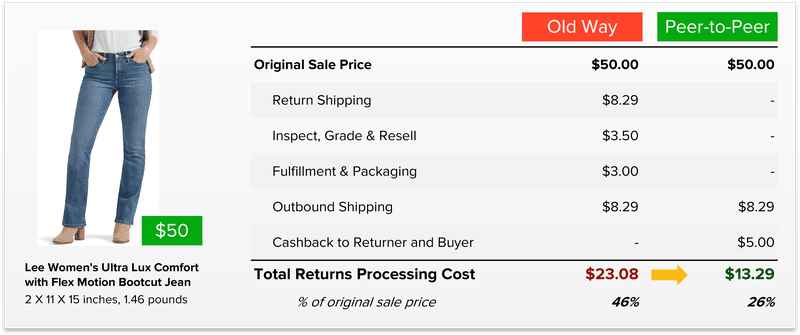

Up to 64% Lower Returns Processing Cost

8 minutes

8 minutes