Preparing for Peak Holiday Shipping Season [Guide for 3PLs]

Last updated on April 16, 2025

In this article

8 minutes

8 minutes

- 2024 Important Dates

- Strategic Demand Analysis, Forecasting, and Marketing Execution

- Optimizing Fulfillment and Logistics

- Transparency and Communication

- Leveraging Technology

- Elevating the Customer Experience

- Preparing Customer Support Teams

- Managing Returns Effectively

- Contingency Planning for Unforeseen Challenges

- Converting Challenges into Strategic Wins

- Frequently Asked Questions

The peak holiday season is the most critical time for e-commerce businesses due to spikes in order volumes, high consumer expectations, and operational complexities. Proactively forecasting with clients, planning logistics needs, and supporting technologies are essential for effectively navigating this high-stakes period. The risk of losing clients due to operational issues that lead to late shipments, late deliveries, and damaged shipments is high.

2024 Important Dates

With Thanksgiving falling on November 28th this year (which is the latest it can fall relative to Christmas), the 2024 holiday shopping season is the shortest that it can be for shoppers who don’t start browsing or buying until November 29th.

Daily shipment volumes can increase by 1,000% or more in ‘normal’ years, placing significant strain on fulfillment operations. However, some will see even higher spikes in demand this year due to the unusually late Thanksgiving Day. So, the shipping deadlines below will feel tighter this year as carrier network capacity is constrained to fewer days. Thus, 3PLs will want to be more proactive in preparing for fulfillment this year (i.e., advancing ship dates as early as possible).

Carrier Published Shipping Deadlines to Ensure Delivery on or Before Christmas Eve

|

Carrier / Service

|

Contiguous U.S. (lower 48 states)

|

Alaska, Hawaii, International, Military

|

|---|---|---|

|

USPS Ground Advantage

|

December 18

|

|

|

USPS Priority Mail

|

December 19

|

|

|

USPS Priority Mail Express

|

December 21

|

|

|

UPS 3 Day Select

|

December 19

|

|

|

UPS 2nd Day Air

|

December 20

|

|

|

UPS Next Day Air

|

December 23

|

|

|

FedEx Ground Economy

|

December 13

|

|

|

FedEx Express Saver

|

December 19

|

|

|

FedEx 2Day & 2Day AM

|

December 20

|

|

|

FedEx SameDay

|

December 24

|

Strategic Demand Analysis, Forecasting, and Marketing Execution

Accurate forecasting is the foundation of successful holiday operations. Working with clients proactively to assess year-over-year sales increase expectations will be key (especially if any big spikes are expected from special promotions or sales such as Good Morning America Deals & Steals). Collaborating with clients well in advance to secure early inbound shipment creation and delivery, including any specialty items such as inserts or branded packaging materials, is critical to prevent stockouts and canceled orders, which impact all three parties negatively (Sellers, Customers, and 3PLs).

Investing the time (well in advance) to learn about the timing of client promotions and the configuration and accurate put away of new SKUs, new bundles and/or kits SKUs, multi-packs, etc., can help increase fulfillment workflow efficiency.

Optimizing Fulfillment and Logistics

Meeting increased demand during the holiday season requires a well-structured fulfillment strategy. Partnering with third parties such as Cahoot can augment a 3PL’s existing operational capacity and benefit their clients by offering distributed inventory options that reduce transit times, lower transportation costs, and increase nationwide on-time delivery reliability. Cahoot’s advanced tools and infrastructure enable 3PLs to rapidly increase scalability to support their growth targets while taking advantage of shipping carrier discounts that can become new profit centers. Likewise, 3PLs can join the Cahoot fulfillment network and create a new revenue stream by fulfilling orders for Cahoot clients.

Transparency and Communication

3PLs should transparently communicate inbound receiving deadlines and blackout dates, including inventory prep and work order (e.g., FBA Prep), and plan to have the staff available to get new inventory inbounded and fulfillment ready by Monday, November 25th. Get containers, FTL, and LTL tracking info, and ensure clients send updates on estimated delivery dates on time. Communicate emergency contact info expectations clearly and well in advance.

Leveraging Technology

Leveling up tech stacks is critical to maintaining efficiency during peak periods and earning customer trust, which can lead to long-term mutual success. Warehouse Management Systems streamline and optimize the movement of goods within a warehouse, ensuring efficient and cost-effective inventory management by tracking its location, quantity, and movement throughout the receiving, storage, picking, packing, and shipping workflows, ultimately enabling overall warehouse productivity and fulfillment accuracy.

Scalable solutions are essential to handle the dramatic increase in holiday orders. Investments in automation, such as robotic picking systems or conveyor technologies, improve efficiency and accuracy. Implementing simple scan verification and next-generation shipping software into the fulfillment workflow achieves a similar result without considerable capital expense.

Elevating the Customer Experience

Third-party logistics providers work for the merchants but ultimately answer to the end customer. It’s the customer experience that the merchants are paying for. Beyond just retention of the client, providing an exceptional on-time shipping and delivery experience can result in growth for merchants, which benefits their fulfillment providers by way of volume growth. Offering real-time order tracking and flexible shipping options results in a high degree of transparency that decreases the customer support burden. Lastly, supporting personalized packaging, including eco-friendly options, branded unboxing experiences, and thoughtful details like gift notes and/or sample products during the fulfillment workflow can leave a lasting impression on customers that increases their lifetime value, which again, trickles down to the fulfillment partner in the form of increased revenue.

A bad experience related to a time-sensitive order can push customers away. Include enough dunnage (void fill) to prevent damage in transit. Ship with the proper hazmat designation so orders are not returned to the sender (and this also ensures that carrier accounts are kept in good standing). Create international shipments for validated addresses using the correct HTS Code, goods description, and compliance with each destination country’s regulatory requirements. Get organized and hand over packages to the correct carriers, another source for potential delays, not to mention the reputation risk for the client/brand.

Preparing Customer Support Teams

The holiday season places heightened demands on 3PL customer service. Merchants are busy supporting their customers, increasing the support required by the fulfillment partner. Expanding support teams and equipping them with the tools and training needed enables quicker, more accurate resolution of inquiries. Comprehensive Help Center self-service content and automated chat solutions provide additional support layers, ensuring seamless communication using the customer’s desired outreach method.

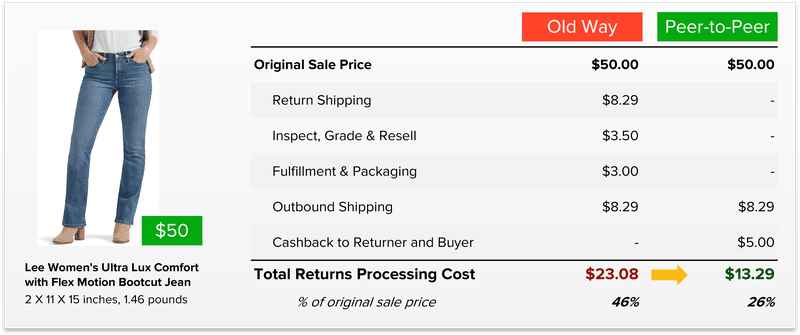

Managing Returns Effectively

Returns rates during the holiday season can approach 30%, a revenue opportunity for fulfillment partners. Establishing an efficient returns processing workflow with clear and easily understandable guidelines is critical to the overall strategy as it reduces client frustration and customer support inquiries. Advanced returns processing and restocking inventory systems minimize revenue losses and improve operational efficiency.

Contingency Planning for Unforeseen Challenges

Even with thorough preparation, unexpected challenges such as extreme weather or carrier delays can arise, negatively impacting a client’s performance metrics and/or customer experience. Flexible contingency plans, including diversified carrier options and alternative fulfillment strategies (such as partnering with a solution provider that supports distributed fulfillment as discussed above), ensure continued operations during local disruptions.

Prepare hardware, such as shipping label printers, well in advance by cleaning printer heads to avoid blurry barcodes that will be returned to sender or delay delivery. Stock plenty of label paper, thermal transfer ribbon, and the like. Consider procuring backup printers, barcode scanners, and packing slip pouches for international customs documents.

Converting Challenges into Strategic Wins

Peak season preparation should begin months in advance. Early steps include finalizing demand forecasts with clients, optimizing inventory positioning, hiring seasonal labor to match the anticipated demand, and testing technical solutions for peak performance. Training teams and conducting trial runs of fulfillment processes help identify and address potential issues before order volumes surge. Maintaining clear communication with all stakeholders and monitoring performance metrics ensures a smooth operation.

The holiday season presents a unique opportunity to demonstrate operational excellence and build lasting client relationships. By focusing on strategic planning, leveraging technology, and prioritizing the customer experience, third-party fulfillment partners can transform the challenges of peak season into a powerful growth opportunity. The most successful organizations approach this period with adaptability, innovation, and a commitment to excellence.

Frequently Asked Questions

How should 3PLs adjust their operations to prepare for the compressed 2024 holiday season?

Start planning earlier than usual due to the shortened season. Inbound inventory should be received and ready for fulfillment by November 25. Collaborate closely with clients to forecast demand spikes and secure labor, storage, and tech capacity early.

What’s the risk if a 3PL fails to deliver during peak season?

Failure to meet service levels during peak season can result in lost merchant clients, negative end-customer experiences, and reputational damage. Clients rely on their 3PLs to preserve brand trust, especially during time-sensitive periods.

How can partnering with Cahoot benefit 3PLs during peak periods?

Cahoot offers distributed fulfillment capabilities that 3PLs can use to reduce delivery times and costs. 3PLs can also join the Cahoot network to monetize excess capacity by fulfilling orders for other sellers, creating new revenue streams.

What tech investments should 3PLs prioritize for peak season readiness?

WMS upgrades, scan verification systems, and autonomous shipping software like Cahoot can dramatically reduce errors. These systems improve picking accuracy, reduce misshipments, and generate compliant shipping labels without human intervention.

How should 3PLs prepare for returns during the holiday season?

Returns may reach up to 30% post-holiday. Establish a clear returns workflow now, including restocking SOPs and communication guidelines for clients. Offering return handling as a value-added service can improve margins and client satisfaction.

Up to 64% Lower Returns Processing Cost