Top 7 Supply Chain Strategies for Making Free Shipping Profitable

Last updated on March 13, 2025

In this article

18 minutes

18 minutes

Free shipping has become an expectation in ecommerce, but for many businesses, it feels like an uphill battle against shrinking profit margins. The key to making free shipping work isn’t just about absorbing the cost, it’s about optimizing your supply chain to offset those expenses. From strategic inventory management to innovative fulfillment methods, businesses that refine their logistics can transform free shipping from a financial burden into a competitive advantage. In this guide, we’ll explore supply chain strategies that not only help sustain free shipping but also attract more customers without compromising your bottom line.

1. Minimize Inventory Storage With Just-in-Time Procurement

Just-in-Time inventory Stocking (JIT) is a common inventory management technique and a lean methodology to increase efficiency. A successful example is the apparel retailer Zara, with its “mind-spinningly supersonic” supply chain. Zara operates in an industry where inventory “spoils” quickly so they commit less than a quarter of a season’s line and produces about half of its line at the start of the season. The remaining? They were designed and produced during the season. Zara identifies popular styles and puts new similar designs in stores throughout the season while they’re still popular. With JIT, Zara improved its cash flow by reducing low-demand inventory while doubling down on what’s working.

Today, online Sellers can quickly gather and process historical sales data to make better demand predictions, but they are still just guesses. And yes, some safety stock is still needed as a buffer, but Sellers don’t need to dedicate as much space for storage as they had in the past. With proper data analysis and planning for smaller but more frequent procurement cycles, merchants can derisk the capital investment and direct the savings into their customer acquisition strategy.

Another application of JIT is cutting storage costs at 3PLs such as Fulfilled by Amazon. FBA is generally an excellent option, but only if the Seller can handle the storage costs (including peak season storage rates and aged inventory surcharges). By estimating their sales via FBA, Sellers can ship items regularly to FBA warehouses in quantities that will sell quickly. The remaining items can be stored in an inexpensive warehouse or their own facility.

2. Buy Online Pick Up In Store (BOPIS)

This is not strictly a solution for improving shipping costs, but it can help the customer get their order on their schedule at a lower cost to you. Buy Online Pick Up in Store (BOPIS) enables customers to pick up their items from one of your physical retail locations. The key here is to eliminate the shipping cost altogether by encouraging the customer to pick up their order.

Customers expect free and fast shipping and in some categories such as grocery, healthcare products, and some household items, fast shipping is a priority over free shipping. You may even want to offer a discount to encourage in-store pick-up which is a win-win for both you and your customer.

BOPIS bypasses the shipping process, cutting delivery from days to mere hours. Moreover, it can be a differentiator between you and a competitor, leading to higher top-line revenue. To minimize additional staffing needs and wait times, self-service package lockers can be used as a touchless way for customers to pick up their orders. Prepared orders are delivered to a locker inside or outside of your store that customers can open via an app or one-time password.

3. Zero Inventory Through Dropshipping

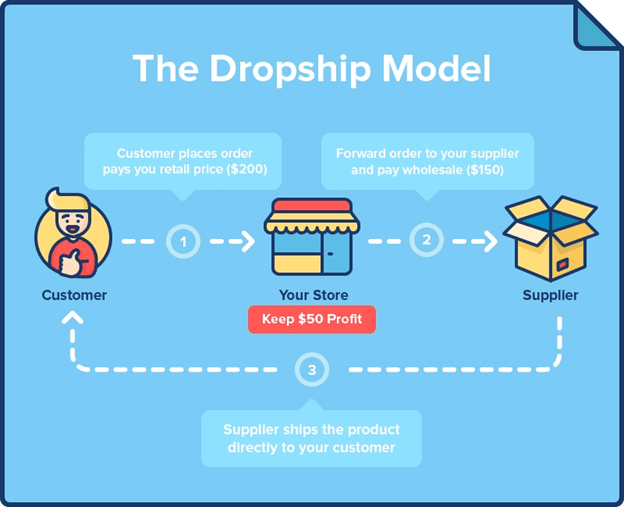

Dropshipping is a popular order fulfillment method used by many online Sellers. Dropshipping is an ecommerce business model that allows retailers to sell products without holding onto inventory. Instead, the retailer forwards customer orders to a third-party supplier who ships the product directly to the customer for a fee. Sellers don’t stock the items in their warehouse, effectively making it a zero-inventory business. When an order for a dropship item is received, the Seller purchases the item from a wholesale supplier who ships the order directly to the customer on behalf of the Seller. Sellers don’t handle or even see the product in the whole process.

Dropshipping has a host of advantages as the online Seller does not require capital to pre-purchase inventory, does not need a warehouse to store it, and doesn’t even need expertise in order fulfillment and operations. However, the Seller must contend with low margins and no control over fulfillment. Therefore, dropshipping should be pursued by Sellers who intend to focus on building a diverse and creative product portfolio and concentrate on marketing to drive sales and revenue growth.

In the dropshipping model, the suppliers assume the risk of unsold inventory, though it’s minimal as they tend to have many affiliates selling their wares, and they pass the cost of logistics to the dropship Seller. Running an assetless business and maintaining low operational costs allows you to offer free shipping while concentrating on improving your sales without worrying about fulfillment.

Another form of dropshipping is cross-docking. In this ecommerce business model, instead of the wholesaler shipping orders directly to their affiliate’s customers, they bulk ship all the days’ orders to the merchant’s warehouse, who then fulfills all the customer orders. Cross-cocking tends to be used by merchants that already have the fulfillment infrastructure and the sunk costs of operating a physical ecommerce business. However, this strategy enables them to sell an expanded product catalog with lower product pricing and logistics fees, which results in higher profitability at a lower risk profile comparable to pure-play dropshipping.

4. Streamlining Your Supply Chain

The supply chain, in general, is not easy to manipulate. However, it’s a good idea to step back and reassess your supply chain for opportunities to improve your cost structure and allow you to offer free shipping.

Here are a few high-level recommendations to streamline your supply chain:

Optimize Sourcing: When you first open an online store, you would typically start with the easiest product sourcing options. As you scale and increase your bargaining power, though, you should look beyond the current sourcing and look for alternative suppliers that align with your selling strategy, which can be a cost leader, highly differentiated, or anywhere in between. You should also consider talking directly with manufacturers, if you’re not already (and using a broker or aggregator), and have a conversation about how you can bring your landed costs down. For example, sometimes overseas factories have preferred freight forwarders with much better ocean container rates than you might currently have available. Ask your 3PL/4PL if they can help with container shipping rates for the same reason…they can often get better rates by aggregating volume across clients.

Optimize Your Order Fulfillment Location: Ecommerce allows businesses to operate from anywhere they can get an internet connection. But as you scale, the inbound and outbound shipping becomes one of the most significant contributors to fulfillment costs. Moving your fulfillment location closer to the customer can save you money AND delight customers with faster shipping; middle of the country, for example (if more than one warehouse is not feasible, though Cahoot makes it easy to add warehouse locations to your existing setup to improve efficiency and reduce cost). On the other hand, being closer to vendors will help you reduce lead time and inbound costs. Both of these factors should be considered in deciding the optimal fulfillment center location. In addition, some locations also enjoy cheaper warehouse rents, cheaper labor costs, and may have government incentives. Taken together, an optimized fulfillment infrastructure can sometimes save substantial money.

Reduce Inventory: As an ecommerce business grows, the common reaction is to increase the size of the warehousing facility as well as the inventory on hand to meet the customer demand. But inventory is a cost trap and increasing inventory should be avoided as much as possible. Explore options such as reducing lead time from suppliers and getting rid of slow-moving inventory. Drastic measures such as liquidation and promotional sale of obsolete items should be standard practices in an industry with dynamic SKUs.

Consider Distributed Inventory: Distributed warehousing is a well-known solution for offering fast and free shipping. Whether leveraging a 3PL service such Amazon FBA, Multi-Channel Fulfillment (MCF), or a 3PL that has many locations, the benefits of distributing inventory to minimize final-mile shipping cost can often improve margins enough to be able to offer free shipping.

Multi-Channel Sales: Many studies have shown that the advantage of selling on many channels is huge. You reach more customers and the topline sales growth increases. This is not different from the conventional brand offering their product through the flagship store, departmental stores, specialty stores, or even outlets. In a similar vein, online shoppers have different channel preferences, and as such, different channels tend to command the attention and loyalty of different demographics. For example, Gen Z is more likely to shop via social channels and be drawn to influencer marketing while millennials prefer comparing different marketplaces and stores. Mix up your strategy to reach more eyeballs to grow revenue and earn the budget needed to cover free shipping.

5. Optimize Shipment Packaging

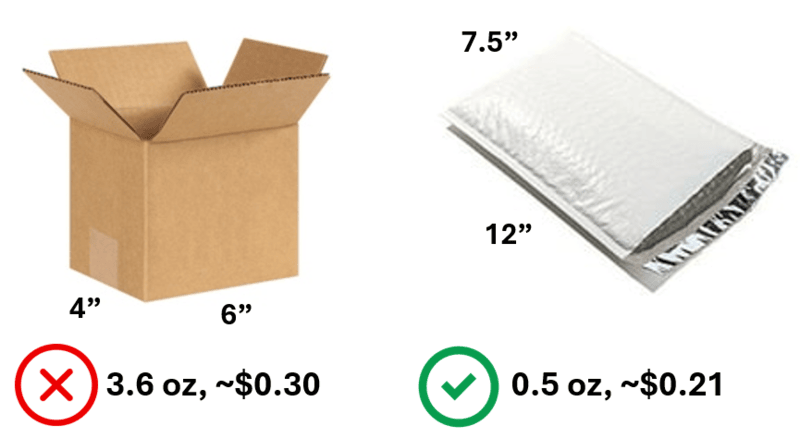

Packaging is an often-overlooked opportunity to optimize shipping costs. Shipping costs are dependent on the size and weight of the package, and online Sellers should look to cut down on both while choosing the optimal packaging. Shipping “air” is throwing money out the window.

If you are using small cardboard boxes, you can cut down on weight and size both by going with poly bubble mailers (if the product can ship and deliver safely in one). Poly mailers are versatile and can accommodate different shapes and sizes of items while keeping the cubic volume and weights low. For example, a poly bubble mailer of size 7.5” x 12” can weigh just 0.5 ounces compared to 3.6 ounces for a small 6”x6”x4” box. Be mindful of only shipping small and strong items using poly mailers like books, cables, or kitchen gadgets. For apparel, some brands like Abercrombie & Fitch use un-padded poly mailers that cost and weigh even less than their bubble-padded brethren.

Another way to cut costs is to use carrier-provided boxes or packaging. All carriers give away free packaging for specific classes of mail. If you are shipping within that service, buying a separate box and affixing the label to it may be more costly than just going with the carrier-provided packaging.

Lastly, consolidate shipping supplies into the 20-ish sizes that are used most often and negotiate bulk discounts to help reduce your packaging costs. As a part of the exercise, take the time to optimize your packaging sizes around the frequency of multi-line/multi-quantity orders by SKU. In other words, figure out the most frequently ordered quantities for your products and purchase the packaging that is optimum for those orders. For example, you may be using the same package to ship multiple quantities of an item like soap. But if your box is designed to accommodate 5 units of soap, and your most commonly order quantity is 2 units, you should consider getting a separate smaller package and save money on the cheaper box or mailer and lower shipping cost. It increases complexity but will save money over time.

Smart cartonization software can be worth its weight in gold and could protect most of your shipping budget by itself by helping you automatically ship in the most economical packaging, minimizing the amount of shipped “air” and extra cost associated with the larger shipment. It can also help you track packaging inventory and alert you when you’re running low.

PRO TIP: Order packaging in bulk directly from overseas manufacturers for the most impactful savings. Buying from domestic suppliers allows you to buy Just In Time and minimize how much is spent at once, but the advantage of saving ~30 – 40% on shipping supplies may far outweigh the convenience of local sourcing in the long run.

6. Reuse Packaging from Inbound Orders

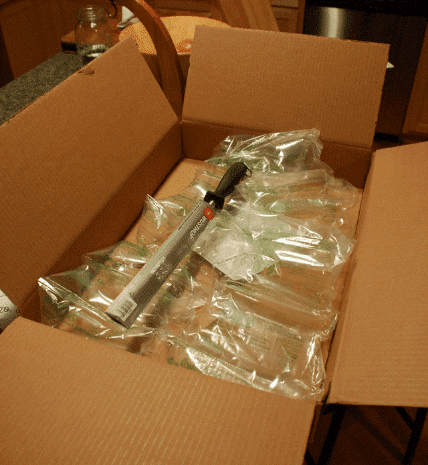

There are two main benefits of reusing supplies from inbound orders. The first is reducing waste (most used shipping supplies are sent to the landfill), and the second is reducing the supplies you need to buy. Packaging supplies like boxes, mailers, and void fill may look trivial when you consider the cost of 1 unit, but en masse, the costs can really add up because they apply to every order shipped.

If you offer fragile or sensitive items that require special packaging, chances are some materials from your inbound shipments can be reused. For example, reusing void fill materials like bubble wrap, peanuts, or crinkled paper can reduce your spending on new supplies while reducing waste. Of course, the amount that can be reused may vary from each Seller, but it’s generally a better idea to reuse before finally recycling them.

Inbound boxes can also be reused to save money here and there, especially if you’re shipping larger items. But be aware that customers can be sensitive to what their package looks like when it’s delivered. If a reused box has old shipping labels, stickers, tape, and/or writing on them, they may have a poor experience and may not buy from you again.

7. Warehouse Robots

Autonomous mobile robotics (AMR) is an exciting innovation in warehousing operations that helps reduce the costs of the picking, packing, and sorting parts of the fulfillment workflow. The robots eliminate the cost of labor from these steps while increasing efficiency. Fulfillment is faster and there are fewer mistakes when a robot conducts an operation. Currently, order fulfillment centers that have robots working alongside humans can transport many more items at once, and in some cases, the complete rack of shelves are brought to stations manned by humans, rather than humans going to the shelves to pick products.

In other cases, robots speed-sort items by weight and volume to be packaged accordingly for different shipping services. This reduces human error while increasing fulfillment speed.

Kiva Systems and 6 River Systems have been two breakthrough AMR robot developers that have helped lower costs significantly for ecommerce Sellers. Kiva specializes in moving the entire shelf of products mentioned previously and was acquired by Amazon for the exclusive use of Amazon fulfillment centers. 6 River Systems was acquired by Shopify and is best known for their collaborative mobile robot named “Chuck” that uses sensors to navigate warehouses, avoiding obstacles and slowing down around people and equipment, guiding workers through their work zones to reduce walking and increase efficiency.

According to Amazon in 2016, Kiva robots cut the cost of warehousing by 20%, which amounts to more than $22 million dollars per warehouse per year. It is estimated that Amazon could save as much as $2.5 billion per year if the robots were deployed to all facilities.

Using robots helps businesses cut the time required to fulfill each order. At the same time, it has allowed better utilization of space by building narrower isles and getting rid of handling mechanisms that were required before.

For a warehouse without any robots, simple solutions such as Automated Guided Vehicles (AGV’s) can be an entry level solution. They are used extensively on factory floors and follow a predetermined path to transport materials without human intervention. This helps reduce manpower. Another solution could be Autonomous Mobile Robots (AMR’s) that can identify their environment and information on packages, where items are located on shelves, and can be used for picking, putaway, sorting, counting, and replenishment tasks, reducing human intervention even further.

Summary

Successful ecommerce businesses don’t just offer free shipping, they master the logistics behind it. Whether through just-in-time inventory, dropshipping, or regional fulfillment centers, the right logistical decisions can make all the difference. Businesses that stay ahead in supply chain optimization will not only keep shipping costs under control but also position themselves for scalable, long-term success. The key is to continuously refine operations, embrace emerging technologies, and find efficiencies that drive long-term savings that can be reinvested into a growth strategy that includes free shipping. With the right approach, free shipping can become a sustainable and profitable part of your business.

Download The Ultimate Guide to Profitable Free Shipping

Frequently Asked Questions

How to lower supply chain costs?

Companies can reduce their supply chain costs by working with suppliers, choosing specialist logistics and warehousing firms, using technology to boost efficiency, and finding ways to reduce waste such as materials or time.

How to reduce the cost of supply chain?

Streamlined processes, efficient transportation, and optimized inventory management all contribute to significant cost savings. By minimizing waste and maximizing resource utilization, businesses can lower expenses and boost profitability.

What is an efficient supply chain?

Supply chain efficiency focuses on delivering quality products to customers at the lowest possible cost by maximizing such resources as materials and labor. Supply chain responsiveness focuses on customers’ expectations and strives to provide a quality product faster.

What is cost control in supply chain management?

It involves optimizing operations to deliver maximum value with minimum waste, thereby impacting the total cost of the products or services. Supply chain managers and leaders have a pivotal role in analyzing and optimizing the supply chain.

Where can I reduce supply chain costs?

Some examples include: avoid minimum order quantities, know your reorder point, get rid of obsolete stock, implement Just-in-Time inventory management practices, and use consignment inventory (or a drop shipping business model).

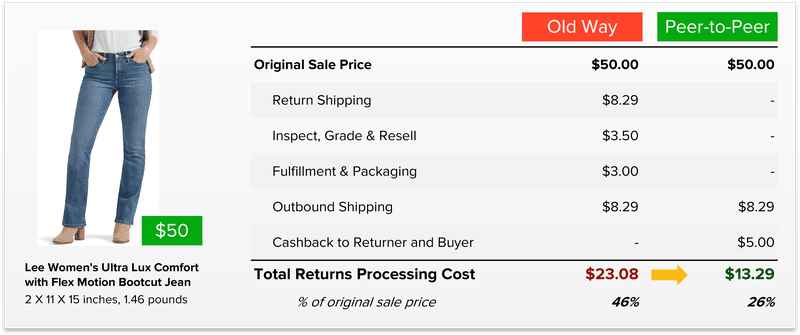

Up to 64% Lower Returns Processing Cost