Understanding 3PL Costs for ECommerce Fulfillment

Last updated on February 28, 2025

Third-party logistics (3PL) providers play a crucial role in helping ecommerce businesses manage order fulfillment efficiently. By outsourcing warehousing, inventory management, picking, packing, and shipping to a 3PL, businesses can save time and resources while providing a consistent and reliable customer experience, but ecommerce fulfillment costs can vary based on order volume, storage needs, and service requirements.

Therefore, understanding the cost structure of third-party logistics (3PL) services is essential for ecommerce businesses looking to budget for logistics. Identifying the different cost components that will apply to the particular situation and calculating the estimated fulfillment expenses associated with using each 3PL being considered should be done well before deciding which one to partner with.

What is a 3PL and How Does it Work?

A 3PL, or third-party logistics provider, is a company that offers comprehensive logistics and supply chain management services to ecommerce businesses. These services can encompass warehousing, inventory management, picking and packing, shipping, and more. By outsourcing these critical tasks to a 3PL, ecommerce businesses can save time and money, allowing them to focus on scaling their operations and enhancing customer satisfaction.

Here’s how it typically works:

- An ecommerce business partners with a 3PL provider.

- The 3PL provider receives and stores the business’s inventory in their fulfillment center(s).

- When a customer places an order, the 3PL provider picks and packs the order.

- The 3PL provider ships the order to the customer.

- The 3PL provider handles any returns or issues that may arise with the shipment.

By leveraging the expertise and infrastructure of a 3PL, ecommerce businesses can benefit from significant cost savings, increased operational efficiency, and improved customer satisfaction. This partnership allows businesses to streamline their logistics processes and focus on growth and innovation.

3PL Pricing Models

3PL pricing models can vary widely depending on the provider and the specific services offered. Here are some common pricing models used by 3PLs:

- Per-Order Pricing: This model charges a flat fee per order, which typically includes picking, packing, and shipping. It’s straightforward and easy to predict, making it ideal for businesses with consistent order volumes.

- Per-Unit Pricing: This model charges a fee per unit of inventory stored or shipped. It’s beneficial for businesses with varying order sizes, as costs are directly tied to the number of units handled.

- Tiered Pricing: This model offers different rates based on the volume of orders or inventory stored. Higher volumes often qualify for lower rates, providing cost savings for businesses with large or growing order volumes.

- Custom Pricing: This model provides customized pricing based on the specific needs of the ecommerce business. It’s tailored to accommodate unique requirements, such as specialized handling or custom packaging.

Understanding the pricing model used by a 3PL provider is crucial to ensure it aligns with your business needs and budget. By selecting the right pricing model, ecommerce businesses can optimize their fulfillment costs and improve their bottom line.

Breakdown of 3PL Costs

The pricing structure of 3PL providers typically involves multiple cost components, including one-time setup fees, ongoing warehousing costs, fulfillment costs, variable shipping fees, and returns processing. Each cost should be carefully considered to determine the total cost of outsourced logistics and its impact on profitability.

Onboarding and Setup Fees

Getting started with a 3PL often involves onboarding and setup costs. These fees cover onboarding, training, integrating systems, configuring product catalog, and aligning workflows with Seller expectations. Businesses might pay anywhere from $100 to over $1,000 for these services depending on the complexity of the requirements, number of SKUs, number of fulfillment centers (for distributed inventory), etc. While this is a one-time cost, it is an essential consideration when switching to a new provider.

Receiving and Inventory Storage Fees

Once inventory is delivered to a 3PL’s facilities, it must be received, inspected, and put away for storage. Fees for receiving are often charged per pallet, per item, or by the hour, and these can include specialized labor costs, especially for items requiring special handling. For example, a provider may charge $5 – $15 per pallet containing 1 or 2 SKUs, or time and materials at an hourly rate of $40 – $50 for inbound processing of mixed cases, containers, and full truckloads. The hourly rate is the most fair for both parties because it’s based on time and materials actually spent on receiving and putting away the inventory.

Storage fees depend on how much space inventory occupies and the pricing model used by the 3PL. Some providers charge per pallet, while others calculate storage fees per cubic foot, per bin, or per shelf. Monthly costs can range from $5 per bin to $40 per pallet, and long-term storage fees (LTSFs) will often apply if inventory remains in storage for extended periods. So it’s wise to ‘right-size’ inbound shipments to minimize storage costs.

Pick and Pack Fees

The foremost task in the 3PLs daily fulfillment workflow is picking and packing orders as they are placed by customers. Fulfillment companies often utilize a pick-and-pack pricing model that charges based on the number of items handled per order. These fees are typically structured per order or per item. A standard pick and pack fee might start at around $2.49 per item, with additional charges for custom packaging, kitting services, or adding inserts (e.g., coupons or thank you messages). If an order contains multiple items, additional picks may be charged at $0.49 – $0.99 per unit or more depending on the size, weight, or complexity of the additional units.

3PLs are pretty split when it comes to charging monthly minimum fulfillment fees. That is, if the pick/pack fee is $2.49 per order (using a single unit in this example), then a $499 monthly minimum fulfillment fee means that the business will pay this minimum whether the 3PL fulfills the 200 units that add up to $499 or not.

Packaging Costs

Many 3PL providers include basic packaging materials as part of their fulfillment services, which can help businesses manage their order volume and shipping requirements effectively. Others pass the actual cost per order directly to the merchant, which benefits those that only need a $0.30 bubble mailer and don’t want to be charged an average price per order (for example, $1.50 per order baked into the fulfillment fee, which is ultimately what’s happening when a 3PL ‘includes’ the cost of shipping supplies). In either case, custom packaging, branded boxes, and eco-friendly options most often cost extra and can add $0.25 – $2.00 per shipment, plus the cost to store the custom supplies.

Shipping Fees

Shipping costs depend on factors like package weight, dimensions, distance traveled, shipping speed, and carrier rates. Some 3PLs pass carrier fees directly to merchants, while others apply a markup. In some rare cases, some 3PLs will allow you to ‘Bring Your Own’ (BYO) negotiated carrier accounts, but more times than not, the aggregation of very large shipping volume means the provider’s rates will be better and save more money as a whole.

Beware 3PLs that give a one-size-fits-all fulfillment price that includes shipping cost. The only way to do that profitably is to use low-cost and less reliable shipping carriers and averaging the shipping cost across all merchants; not charging for just what they use. Shipping price transparency is best. And since shipping is often one of the largest expenses in order fulfillment, businesses should analyze their historical shipping distribution and work with the 3PL to pick the best warehouse location (or locations) to minimize final mile shipping costs to their customers.

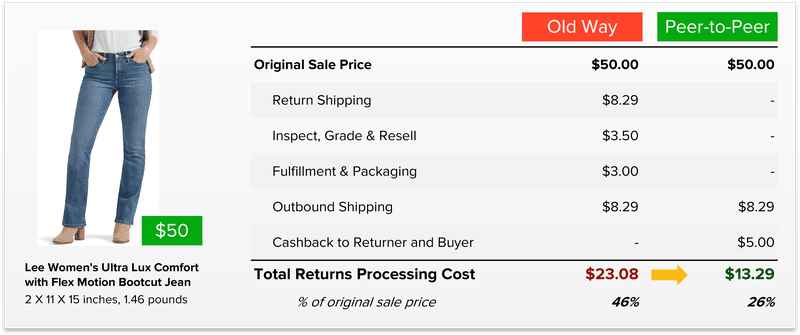

Returns Processing

Handling product returns involves additional labor and logistics. Many 3PLs charge fees for receiving, inspecting, restocking, or disposing of returned items. These fees vary but may include per-item charges, such as $3.99 per unit, or time and materials labor rates in the $40 – $50 range. Efficient returns processing can enhance customer satisfaction while minimizing additional costs.

*Shipments that are returned to sender by the carrier (not a return intentionally initiated by a customer) may also fall into this category, and storage fees will resume when the item is delivered back to the fulfillment center.*

Platform Fee

Some 3PLs charge a platform or technology fee for the continuous improvement and development of the software and services. It might run anywhere from $49 – $999 per month depending on the complexity of the software and services that are being provided.

Account Management and Support

Some 3PLs charge monthly account management fees, especially for businesses requiring dedicated support, quarterly business reviews, or advanced reporting. Fees can range from $75 – $250 per month or $40 – $60 per hour for support services. These costs ensure smooth and reliable communication and speedy issue resolution.

How to Calculate Total Fulfillment Cost Per Order

To determine the total cost per order, businesses must factor in all relevant expenses. A simplified formula for calculating fulfillment costs (less shipping cost which is highly variable) looks like this:

Total Warehouse Storage Fee = Number of pallets × Storage Fee per pallet

Total Pick & Pack Fee = (Number of orders per month, first unit × Pick & Pack Fee per first unit) + (Number of additional units per month × Pick & Pack Fee per additional unit)

Total Receiving Fee = Number of units received every month × Receiving Fee per unit, OR, Time and Materials spent receiving every month × Receiving Fee per hour

Total Monthly Fulfillment Cost = Storage Fee + Pick & Pack Fee + Receiving Fee

Cost Per Order = Total monthly fulfillment cost ÷ Number of orders per month

This calculation helps businesses estimate their fulfillment expenses and assess the cost-effectiveness of outsourcing logistics. Note that while shipping cost is not included in these calculations, many 3PLs should be able to analyze shipment history and provide a fairly accurate forward-looking shipping cost estimate.

Factors That Affect 3PL Pricing

Pricing can fluctuate based on several factors, including:

- Order Volume or Order Volume Commitments: Higher volumes may qualify for bulk discounts.

- Product Characteristics: Heavy, oversized, and fragile items often require additional handling, more substantial shipping supplies, and higher storage fees.

- Warehouse Location: Proximity to customers can impact shipping costs and delivery times. It’s best to partner with a 3PL that can manage distributed inventory across a minimum of 2 strategically located warehouses, but 4 or more locations might be warranted if expedited shipping options are being offered to customers.

- Seasonal Demand: Increased storage or expedited services during peak sales periods may add surcharges.

Choosing the Right 3PL for Your Ecommerce Business

Selecting the right 3PL for your ecommerce business can be a complex decision. Here are some key factors to consider:

- Services Offered: Ensure that the 3PL provider offers the services you need, such as inventory preparation (e.g. barcoding, polybagging), FBA forwarding, and/or support for hazardous materials. Comprehensive services can streamline your operations and reduce the need for multiple vendors.

- Pricing: Compare pricing models and rates among different 3PL providers to ensure you’re getting the best deal. Look for transparent pricing structures that align with your budget and business model.

- Reputation: Research the 3PL provider’s reputation online and ask for references from other ecommerce businesses. A provider with a strong track record of reliability and customer satisfaction is essential.

- Technology: Ensure that the 3PL provider has the technology and systems in place to efficiently manage your inventory and orders. Advanced technology can enhance accuracy, speed, and overall efficiency, which keeps cost down by design.

- Scalability: Choose a 3PL provider that can scale with your business as it grows. The ability to handle increased order volumes and expand services is crucial for long-term success.

By carefully considering these factors, you can select a 3PL provider that meets your business needs and helps you achieve cost savings and improved customer satisfaction.

Hidden Costs to Watch Out For

When partnering with a 3PL provider, it’s important to be aware of potential non-obvious costs that can impact your budget. Here are some examples:

- Handling Fees: Additional handling fees may be charged for tasks such as kitting, assembly, or special packaging. These fees can add up, especially for businesses with complex product requirements.

- Storage Fees: Storage fees for inventory stored in the fulfillment center can add up if too much space is being occupied compared to the order volume, or if too many warehouses are storing inventory unnecessarily. Long-term storage fees may apply if inventory remains in storage for extended periods, and some 3PLs charge fees for each warehouse where stock is stored, so it’s wise to optimize inventory storage through strategic and active management.

- Account Management Fees: Some 3PL providers charge extra for account management services and let merchants self-manage their operations to minimize overall cost. It’s important to first know if they are needed, and therefore included, or if charges will only apply to account management or consulting services actually rendered.

- Credit Card Fees: Business credit card transaction fees charged by banks can be passed on to fulfillment services clients. The cheapest option is to pay invoices by ACH or wire transfer to eliminate or reduce bank fees.

By understanding and anticipating these non-obvious costs, you can better manage your budget and ensure that you’re getting the best value from your 3PL provider. Careful planning and regular reviews of your 3PL partnership can help you avoid unexpected expenses and maintain cost-effective operations.

Making an Informed Decision

While cost is a significant factor in selecting a 3PL, businesses should also evaluate service quality, fulfillment speed, technology capabilities, and scalability. The cheapest provider may not always offer the best long-term value if inefficiencies or delays lead to fulfillment defects and dissatisfied customers.

Outsourcing fulfillment to a reliable 3PL can streamline operations, reduce overhead, and allow ecommerce businesses to focus on growth. However, understanding the full scope of costs and conducting thorough comparisons will ensure that the partnership aligns with financial and operational goals.

Frequently Asked Questions

What does 3PL stand for?

Third-party logistics company. A third-party logistics company (3PL) is a service provider that either arranges or handles a variety of supply chain functions for a business. These functions can include brokering, shipping, storing, or packing a company’s freight, as well as supply chain strategy and access to technology.

Who needs 3PL?

Typically used by larger ecommerce companies, 3PLs optimize your company’s logistics network by providing services ranging from accounting and cost control to freight forwarding, inventory tracking and management, and similar functions. Some larger 3PLs offer services in all of the above areas for their clients.

Is it cheaper to use a 3PL?

3PLs can provide lower costs on order fulfillment by leveraging economies of scale to offer better rates for shipping, packaging supplies, warehousing services, etc. A 3PL can typically reduce transportation costs by 5% – 20% or more, and ensure full management of your inventory while using up-to-date equipment and software.

Is a 3PL worth it?

One of the key advantages of using a 3PL is its ability to maximize speed and efficiency. As your business grows, a 3PL can handle increased order volume without the need for additional staff. They also leverage their network to negotiate lower shipping rates and expedite delivery times.

Is Amazon a 3PL or 4PL?

Two of Amazon’s businesses, Fulfillment by Amazon (FBA) and Amazon Multi-Channel Fulfillment (MCF), can be classified as 3PL providers. FBA is a warehousing and fulfillment service for orders placed on Amazon.com only.

Up to 64% Lower Returns Processing Cost

13 minutes

13 minutes