Warehousing Services: How to Pick the Right Provider

Last updated on February 7, 2025

As ecommerce gains a larger share of the total retail market, the demands on warehouses keep growing. While the underlying principle of what a warehouse is remains the same, the actual processes run within warehouses look far different from what they did even 20 years ago. Warehousing services have evolved from simple storage solutions into integral components of the global supply chain.

Products need to be stored securely and handled properly, and multi-channel ecommerce orders need to be delivered on time, all of which directly impact a merchant’s revenue and profitability. Efficiently handling long-term storage, Business-to-Business (B2B) replenishment, and online direct-to-consumer (DTC) orders is a tall task for any one warehouse, and rising consumer expectations are pushing costs higher.

What seems like a simple decision – where to store your products before last mile delivery – can get complicated in a hurry. Understanding the breadth of warehousing services, their benefits, and how to choose the right outsourcing partner is crucial to optimizing for success.

What Are Warehousing And Fulfillment Services?

Simply put, warehousing is the term for the storage of inventory before the goods are sold. Warehouses focus on storing inventory inexpensively, securely, and in a way that supports necessary access to the goods. Warehousing can occur at many steps along the supply chain: manufacturers need to store products, warehouses are often needed to help with middle mile distribution, and inventory is stored in a warehouse until it’s shipped to a customer. Within the enormous category of ‘supply chain’, there are many different types of warehouses that may or may not specialize their offerings. But the four primary types of warehouses are:

Public warehouses

These facilities offer short-term and long-term storage solutions for multiple clients, making them a cost-effective option for businesses with fluctuating inventory or order fulfillment needs.

Private warehouses

Owned and operated by a single business, private warehouses provide maximum control but require significant investment.

Bonded warehouses

Used for storing imported goods before customs duties are paid, allowing businesses to manage international shipments efficiently.

Fulfillment warehouses

Specializing in ecommerce and DTC shipping, these warehouses focus on quick and high-volume order fulfillment (often same-day).

Warehouse specializations include things like:

- Temperature-controlled storage for perishable items, pharmaceuticals, and food products.

- Sustainable warehousing that supports brand reputation and image by using energy-efficient operations such as microgrid implementation for warehouse energy independence and decarbonization, and eco-friendly packaging such as fully organic mycelium-based materials.

- Secure storage for high-value items such as electronics, luxury goods, and jewelry that may require different security measures.

- Hazardous materials storage that requires warehouses to comply with safety regulations (e.g., chemicals, flammable goods, lithium-ion batteries).

- Food-grade warehouses require certification and stringent hygiene and temperature control standards if they prepare food products.

- FDA Food Facility Registration (FFR) for facilities that store and ship food products.

Essential fulfillment services, such as picking, packing, shipping, and storage, are fundamental offerings provided by fulfillment warehouses. Their services are crucial for developing an effective ecommerce fulfillment strategy. These are the warehouses that have seen the most change over the past few decades as they’ve shifted from focusing entirely on B2B orders (pre-ecommerce era) to being able to fulfill a large number of Business-to-Consumers (B2C) orders straight from their shelves.

How has that shift impacted warehousing & fulfillment services?

Definition And Purpose Of Warehousing Services

Warehousing services refer to the storage and management of goods in a designated facility, playing a critical role in the supply chain. These services provide a central point for receiving, storing, and shipping products, ensuring that goods are managed properly and maintain their quality and availability as the market demands. By acting as a hub in the supply chain, warehousing services help streamline the flow of goods from manufacturers to customers, reducing delays and improving overall efficiency. Warehouse services also include closely related inventory management and logistics functions.

Logistics services (a.k.a inventory management and logistics functions) play a crucial role in warehouse fulfillment operations by offering efficient and cost-effective solutions for attending to the modern merchant’s needs (e.g., inventory preparation such as kitting and barcoding, or FBA forwarding, etc.). Not all warehouses provide these services, but they play a vital role in the success of today’s multi-channel ecommerce sellers. They should not be overlooked when considering whether to partner with a provider.

Not to be confused with distribution centers and distribution services that focus on facilitating the movement of goods between fulfillment centers, businesses also require these services and will need to separately evaluate their operational needs to determine the right mix of ecommerce order fulfillment and bulk storage and distribution services.

Inventory Management And Storage

Much of the floorspace in a warehouse is dedicated to inventory storage, but how inventory is stored has changed dramatically thanks to the shift toward ecommerce order fulfillment. Efficient warehousing is essential for clothing retailers, for example, to manage inventory effectively.

Warehouses focusing on B2B replenishment store their inventory efficiently in large bundles – think of a full pallet of goods or a pallet of goods from which multiple cases can quickly be picked. Relatively little is needed to receive the goods and put them into storage: if orders are pallet-sized, then they might not even need to be unpacked at all.

Contrast that with inventory storage at a warehouse that fulfills ecommerce orders – goods have to be stored in such a way that they can be easily picked in eaches (single unit quantities). When an ecommerce warehouse receives pallets of inventory, they have to unpack the pallet, put away cases of goods, and then open some of the cases so that they can easily access the products inside. The speed with which a warehouse picker can get to the items and pull one or more out of the carton becomes of paramount importance because they have to repeat the process hundreds of times per day.

Thus, the explosion of ecommerce has been accompanied by an explosion in warehouse automation as providers try to make their operations ever more efficient. When storing products, warehouse personnel must be able to pinpoint the exact location of all SKUs quickly, count the number of units on hand, and respond to recalls. Each of those tasks can be made considerably easier with the intelligent use of technology, like barcode scanning. Another [very high-tech] example making waves in 2025 is augmented reality-powered inventory management: implementing AR technology for real-time, hands-free inventory tracking and optimization in warehouse environments. These are very expensive systems, but the ROI on the investment is substantial.

Ecommerce Order Fulfillment

Moving from a handful of large B2B orders every day to thousands of B2C orders per day is a massive shift. Just like the changes to warehouse storage strategy, a change in fulfillment strategy has led to a significant increase in the complexity and cost of warehousing.

Warehouses need to employ more fulfillment personnel and deploy more technology in order to get products from storage into boxes or mailers and affixed with shipping labels as quickly as possible. Amazon Prime’s continual push to cut delivery times shorter means that warehouses can’t wait to fulfill orders; each customer that presses “buy” needs to have their item picked, packed, and handed over to a national carrier that same day.

Amazon SFP support

Speed is the name of the game when it comes to the Amazon Seller Fulfilled Prime (SFP) program. Amazon’s requirements are so intense that barely a half-dozen providers in the entire country have the infrastructure and resources to support it.

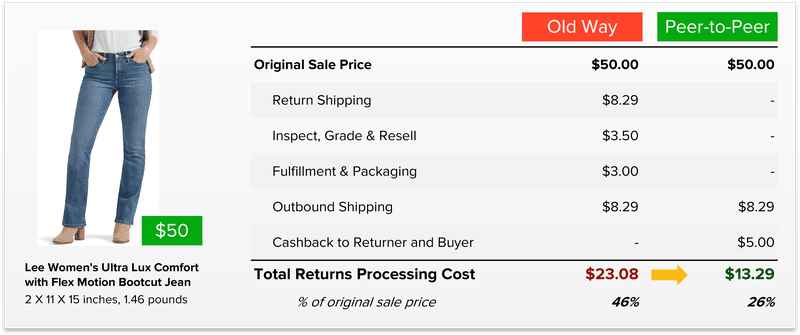

Returns Processing

Ecommerce warehouses must be able to process returns as one of its services – those that don’t leave their clients unable to provide a critical service to their customers. Marketplaces again have led the market with super-easy no-fault returns policies, so online merchants of all stripes are under heavy pressure to offer the same on their DTC sites. So, warehouses have to be able to receive returns, assess whether they’re damaged or not, and process them back into available stock whenever possible to minimize loss from returns.

Consolidation

Consolidation involves combining multiple smaller shipments into one larger shipment to reduce transportation costs and improve efficiency. Goods are picked, sorted, and packaged before being transported as one unit, leveraging economies of scale. Common uses include retail restocking and FBA forwarding, where shared truck space minimizes expenses and environmental impact while maintaining delivery reliability.

Deconsolidation

Deconsolidation is the breaking down of large amounts of inventory into smaller batches for efficient regional distribution. Goods are unpacked, sorted, inspected, and repackaged for delivery to separate fulfillment centers. This service prioritizes speed and accuracy, enabling rapid redistribution of inventory for faster and cheaper delivery to customers.

Cross-docking

Cross-docking is a logistics strategy where incoming goods are transferred directly from inbound to outbound transportation with minimal or no storage. Products arrive at a warehouse, are sorted, and immediately reloaded onto outbound vehicles bound for final destinations. This warehouse service prioritizes speed, eliminates warehouse holding time, and is ideal for perishables, time-sensitive retail goods, or high-turnover inventory.

Transloading

Transloading is the transferring of inventory between different transportation modes (e.g., freight container to truck van). Goods are unloaded from one carrier and temporarily stored if needed (usually hours or days, not weeks or longer), and then they are reloaded onto another carrier. Transloading enables cost-effective long-haul shipping.

Benefits Of Using Warehousing Services

Using warehousing services can bring numerous benefits to businesses, including:

- Cost Savings: By leveraging shared storage space and economies of scale, businesses can significantly reduce costs associated with storage, labor, and transportation.

- Improved Efficiency: Warehousing services optimize inventory management, reducing the need for frequent transportation and minimizing handling costs. This leads to a more streamlined and efficient supply chain.

- Enhanced Customer Satisfaction: Timely delivery of products is crucial for customer satisfaction. Warehousing services ensure that products are stored strategically and shipped promptly according to defined service-level agreements (SLAs), improving customer loyalty and satisfaction.

- Scalability: Warehousing services offer the flexibility to scale up or down according to changing market demands. This adaptability is essential for businesses looking to grow or adjust to market fluctuations like peak season demand.

How To Choose The Right Warehouse

Choosing the right warehouse to support your business can be a daunting proposition. There is a huge variety of services provided by warehouses and 3PLs, and it can be difficult to figure out what each company specializes in at first glance.

One crucial factor to consider is the availability of specialized services. These services can include order picking, packing, and specialized handling for unique products like beauty items, perishables, or fragile glass beverages that require custom shipping containers to avoid breakage in transit, which go beyond basic inventory storage and fulfillment.

What are the key criteria that you should keep in mind?

Key Considerations

- Technology: Advanced warehouse management systems (WMS) ensure efficiency, real-time tracking, and visibility of inventory and shipment status.

- Scalability: The warehouse should be able to accommodate growth and seasonal demand fluctuations.

- Geographic Location: Proximity to major distribution hubs and ports reduces inbound shipping costs, and locations in major metro areas decrease overall shipping costs and delivery times.

- Shared vs. Dedicated Warehousing: Shared services are cost-effective and flexible, while dedicated space and resources provide peace of mind and special attention but come at a higher cost.

Sales Channels

Where are you selling now? What’s your growth strategy?

Many online sellers get their start on Amazon and rely on Fulfillment by Amazon (FBA) for their warehousing and fulfillment. It’s only suitable for selling on Amazon, though, so they quickly find that they need an FBA alternative for their non-Amazon sales volume. The same is true of sellers that rely on Walmart Fulfillment Services for their Walmart volume; its warehouses are reserved for its own channel only. If you want to sell direct-to-consumer, or if you want to sell on more channels than just Amazon and Walmart, you can’t solely rely on those warehouse solutions. Today’s marketplace space is very diverse: Target Plus, Nordstrom, Macy’s, Wayfair, and more are thriving.

Stepping outside the big marketplaces, you’ll find that many warehouses and 3PLs specialize in either B2B or B2C orders, not both. Picking a specialist provider can be a strong strategy for sellers who are certain they’ll never want to cross over from retail to online sales or vice versa, but most have ambitions to grow on both channels.

If you’re currently selling both B2B and B2C or have plans to do so, you should know that there are providers that can do both at a high level. Many sellers start out with a warehouse that specializes in the one channel on which they sell (like FBA for an Amazon seller or a single Shopify 3PL for a DTC brand). Then, they add different warehouse and fulfillment companies as they grow to new channels that their existing provider can’t address.

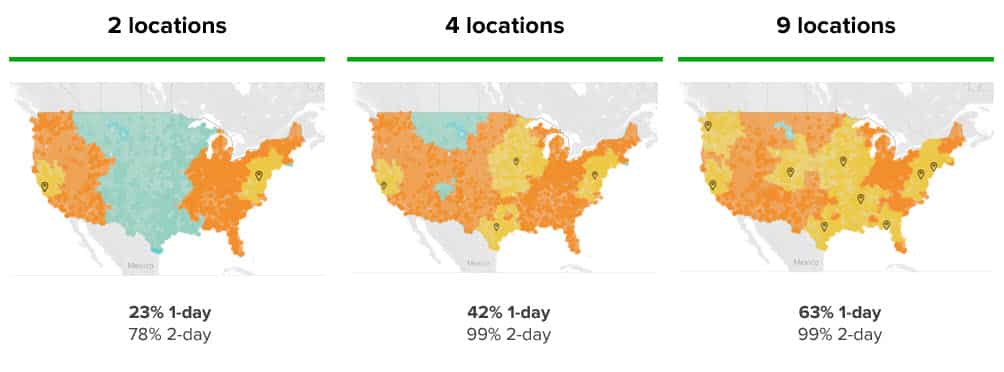

On the other hand, flexible 3PL networks like Cahoot will scale with you and seamlessly add the warehouse capacity you need for whatever channels you’re adding. Thanks to our peer-to-peer model, we have a dense network of many different types of warehouses – so we can consolidate your fulfillment needs into a single organization and customize our approach to your evolving needs.

It’s not so simple, though – most sellers have fast-movers and slow-movers in their catalog. Their hero SKUs generate an outsized chunk of their profits, but they need the “long tail” to bolster their brand and provide holistic value to customers. These slower movers are most efficiently stored in less expensive areas of the country, and moreover, they’re difficult to distribute around the country because that strategy significantly increases inventory carrying costs. In short, you want an entirely different warehousing strategy for your slow movers from your fast movers.

Some fulfillment networks like FBA specialize in fast movers only; most Amazon sellers have learned this painful lesson from getting hit with restrictive FBA limits that push all but their best sellers out of the service. Many of the tech-enabled 3PLs like Flexport have adopted similar models, and they all have similar markers: they have strict limitations on the inventory they’ll accept (and in particular, they don’t like large items), they charge huge long-term storage fees, and they put punishing surcharges on storage and fulfillment during peak seasons.

You can choose a mixed warehouse strategy in which you use fast-turn-optimized fulfillment centers like FBA for your fast movers and more efficient, low-cost providers for your slow movers. This can work, but it also requires a large amount of managerial time, and you’ll find yourself frustrated when you have too much inventory in one warehouse and too little in another. Alternatively, more innovative networks like Cahoot bring together warehouses that specialize in fast movers, slow movers, B2B orders, and everything in between. That way, you can consolidate your operations with one provider, simplify your life, and enjoy economies of scale.

On top of these considerations, the recent resurgence of volatile supply chain issues adds another wrinkle to your warehousing decision. Many sellers are opting to stock up on as much inventory as they can in advance because they know that “just in time” shipments from overseas will likely not arrive when they are estimated to. This adds another need for super-efficient storage – if you try to keep 6+ months of inventory in a warehouse optimized for B2C fulfillment, you’ll rack up ruinous storage fees. If you’re going to be bringing in more inventory than usual, our advice is to find a long-term storage warehouse in a relatively low-cost area close to your port of entry. There’s no avoiding the fact that you’ll have to pay more to store this inventory than if you brought it in “just in time,” but you can mitigate the cost with this approach. And if you’re stuck with extra inventory and no place to put it unexpectedly (for instance, from reduced FBA inventory limits), then you’ll need on-demand warehousing.

In the same vein, efficient management of raw materials is also crucial in inventory management, especially for industries like automobile manufacturing and food services. Proper storage and distribution of raw materials ensures timely order fulfillment and smooth operations.

Technology Needs And Warehouse Management Systems

Whether you sell online, wholesale, or both, you can’t avoid having a complicated tech stack in the 21st century. Even ten years ago, many warehouses were still operating via Excel spreadsheets – customers would email over the previous day’s orders, and the warehouse would get to work shipping them out. Warehouse operations have changed dramatically, and you need to carefully understand what technologies your warehouse can integrate with.

It starts with sales channels, ecommerce platforms, and order management systems: does your chosen warehouse have a pre-built integration with the services that you use? Does it have an open API and developer support so that you can connect lesser-known channels or custom technology to the warehouse? If you want efficient operations, at a minimum, your warehouse should automatically receive orders from you and then automatically update all of your customer management, inventory management, and ERP software with shipment information. It’s not easy, and many warehouses and 3PLs have struggled to make the digital transition.

On top of that, the technology that your chosen warehouse(s) use to operate day-to-day can have a significant impact on your total costs. Most warehouses and fulfillment centers make the shipping label decision for you because the label has to be printed on location. If they’re relying on an older shipping software, they likely have to pick shipping labels manually. This often leads to you paying more than you need to because they won’t always pick the optimal label. Next-gen shipping software completely removes the human from the process and autonomously identifies and creates the best shipping labels. They will automatically rate shop all of the supported carriers and pick the lowest-cost delivery service that meets your SLA. In this way, your warehouse’s technology substantially impacts your total fulfillment cost.

Warehousing Services Recap

Your needs for warehousing services can vary dramatically based on what and where you’re selling – from the humble long-term storage warehouse to the highly automated fulfillment center.

Many sellers take a piecemeal approach to warehousing as they grow; they’ll start with a 3PL that meets their initial use case but quickly outgrow it and have to add multiple providers. Keeping up with a broad set of warehouse providers is time-consuming and inefficient, especially when transferring inventory between locations and across software systems. But new warehouse and fulfillment networks are here to address the challenge.

Cahoot’s innovative peer-to-peer network has the flexibility to cover a wide range of use cases, all under one company (and multiple warehouse roofs).

Cahoot’s fulfillment network is built for the ever-shifting needs of growing ecommerce sellers. We’ll help you delight your customers with a stellar, Amazon-like delivery experience no matter where you sell. We have pre-built integrations with major marketplaces, shopping carts, listing services, carriers, and ecommerce platforms to fuel your multi-channel growth.

We don’t stop there, though. We’ve expanded our dense network to add significant B2B capabilities so that we can efficiently support retail replenishment.

We can do this while others can’t because our warehouses are operated by merchants just like you with excellent fulfillment operations. There are millions of unique merchants in the US, and chances are that we have a few merchant clients just like you.If you need warehousing services built to help you scale into the future, contact us for a free consultation today.

FAQ

What are warehousing services?

Warehousing is the process of storing goods in a warehouse for the purpose of distribution, sale, or manufacturing. Warehouses are used for storing goods for an extended period of time and are typically equipped with storage areas, shelving, loading docks, conveyors, forklifts, pallet jacks, and other inventory-handling equipment. Businesses can benefit from warehousing in several ways, including more efficiently managing inventory and optimizing the shipment process.

What do warehousing companies do?

Warehousing companies provide facilities to store goods. They do not sell the goods they handle. These businesses take responsibility for storing the goods and keeping them secure. They may also provide a range of services, often referred to as logistics services, related to the distribution of goods.

Is warehousing the same as storage?

Warehousing is typically a temporary holding place for goods, with products moving in and out regularly. Storage can be short-term or long-term, depending on the specific requirements. Warehouses are often large facilities with ample space for storing and maneuvering goods.

Why would a business use warehousing?

Warehousing provides companies with a centralized location to store, manage, and distribute their goods to their end customers. This reduces the complexities involved in inventory monitoring and management and cuts down staffing needs and operation costs.

How much does warehousing cost?

On average, businesses can expect to pay between $5,000 and $25,000 per year for smaller co-warehousing spaces of less than 3,000 square feet and between $50,000 and $500,000 per year for a larger warehouse lease, urban areas commanding the higher end of the range.

How to calculate warehousing cost?

Measure Your Space: Start by measuring the total square footage of your warehouse. This measurement is the foundation for calculating many of your storage costs. Calculate Cost Per Square Foot: Determine the cost per square foot by dividing your total operating costs by the warehouse’s total square footage.

Up to 64% Lower Returns Processing Cost

17 minutes

17 minutes